Warwick Mills shows the kind of innovative know-how common among American textile companies that have survived the fierce global competition of recent years.

The small private company in New Hampshire has climbed steadily up the economic ladder of its industry to produce specialized fabrics that weave in ceramics, metals and fiberglass. These high-value fabrics are used in products like safety gloves for industrial workers and body armor for the police and military.

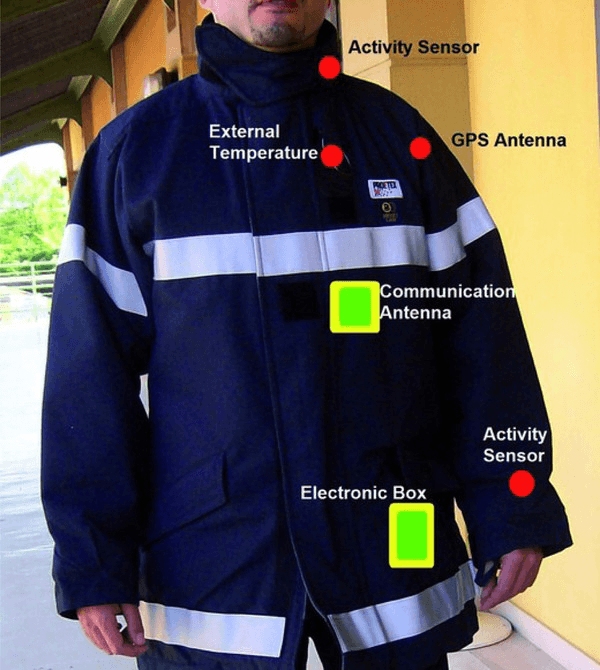

Now, Warwick Mills is joining the Defense Department, universities including the Massachusetts Institute of Technology, and nearly 50 other companies in an ambitious $320 million project to push the American textile industry into the digital age. Key to the plan is a technical ingredient: embedding a variety of tiny semiconductors and sensors into fabrics that can see, hear, communicate, store energy, warm or cool a person or monitor the wearer’s health.

“These would be high-tech offerings that change the game for the companies involved and for the industry,” said Charles Howland, president and chief engineer of Warwick Mills.

The advanced fabrics project, which is being announced on Friday, represents a new frontier for the Internet of Things. The term describes putting sensors and computing in all manner of physical objects — jet engines, power generators, cars, farm equipment and thermostats, among others — to measure and monitor everything from machines in need of repair to traffic patterns. Venture capitalists, start-ups and big corporations like General Electric and IBM are rushing to Internet of Things technology.

This latest initiative, Advanced Functional Fabrics of America, is intended to create a national network of research and development, design and manufacturing capabilities for the new fabrics. The products of this emerging field are being called “functional fabrics,” “connected fabrics,” “textile devices” and “smart garments.”

The field requires contributions from many disciplines, including materials science, electrical engineering, software development, human-computer interaction, advanced manufacturing and fashion design.

The Defense Department is investing to develop new combat uniforms that might communicate and change color, signaling friend or foe to help prevent deaths by friendly fire, or uniforms filled with optical sensors to make a soldier invisible to an enemy’s night-vision goggles. So far, the Pentagon, more than 30 universities, 49 companies and the state governments of Massachusetts and Georgia have agreed to participate, and more are expected to join.

Some of the pioneering research has been done at M.I.T., which is leading the project. Advanced research, in the precompetitive stage, will be published and shared.

Learn more: U.S. Textile Industry Turns to Tech as Gateway to Revival

The Latest on: Smart garments

[google_news title=”” keyword=”smart garments” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Smart garments

- What Wall Street finance bros should wear this summeron May 8, 2024 at 2:24 am

Wall Street is back in the office, and finance bros are having to ditch the sweatpants. Here's what style experts say they should wear this summer.

- Review: When Japan became modern: Meiji-era art and artifacts are now at Smart Museumon May 7, 2024 at 3:30 am

Fifty Years of New Japan” is a building-wide exhibition and much of it shows a fusion of old and new, traditional and modern, Japanese and foreign.

- Smart packing: How to travel light and stylishon May 6, 2024 at 10:55 pm

The key to a light suitcase is selecting versatile clothing. This article will steer you through picking multi-functional pieces that save space and maintain your fashion sense. Learn to pack smart ...

- Sweden offers Bangladesh partnership for garment sector sustainabilityon May 5, 2024 at 7:55 am

Sweden has offered Bangladesh to work for green transition in the garment sector on partnership basis. The European nation made the offer when its ambassador to Bangladesh Alexandra Berg Von Linde ...

- Smart search shirt: AHRS invention group’s garment will report rescuers’ vital signs and locationon May 3, 2024 at 9:50 pm

Understanding the risks they take, a group students at Amherst Regional High School, known as an InvenTeam, is creating a smart garment that can easily be put on and worn by rescuers ...

- The Best Garment Bag There Ison May 3, 2024 at 2:06 am

Bennett Winch, the first luggage brand ever to open on Savile Row, has introduced a clever new bag designed for keeping clothes smart during short-term trips. Handmade in England, the Trifold is a ...

- Researchers explore nano-printing for smart textileson May 2, 2024 at 2:35 am

Described as ‘nano-printing’, the technology involves integrating functional nano-materials directly into textile fibres to produce ‘smart clothing’ that avoids the use of bulky components that can ...

- Save The Duck Redefines Everyday Comfort with New Smartleisure Collectionon April 29, 2024 at 3:39 am

In addition to these refined technical styles, Save The Duck opts for a palette of beige, khaki green, brown as well as deeper tones of blue and red. Washed over the garments in one single color block ...

- Hisense Unveils The Revolutionary 7S Smart Laundry Washer & Dryer, Redefining Garment Care In MENA - Middle East Business News And Informationon April 26, 2024 at 1:15 pm

Dubai, United Arab Emirates– Hisense, a leading global provider of consumer electronics and premium home appliances, has today announced the launch ...

- Hisense Unveils the Revolutionary 7S Smart Laundry Washer & Dryer, Redefining Garment Care in MENAon April 26, 2024 at 3:11 am

Hisense, a leading global provider of consumer electronics and premium home appliances, has today announced the launch of the groundbreaking 7S Smart Laundry Washer & Dryer in the MENA region. This ...

via Bing News