Researchers at a California, U.S.-based laboratory claimed to have successfully printed three-dimensional (3D) ceramic parts capable of withstanding high temperatures while retaining crucial strength.

Researchers at a California, U.S.-based laboratory claimed to have successfully printed three-dimensional (3D) ceramic parts capable of withstanding high temperatures while retaining crucial strength.

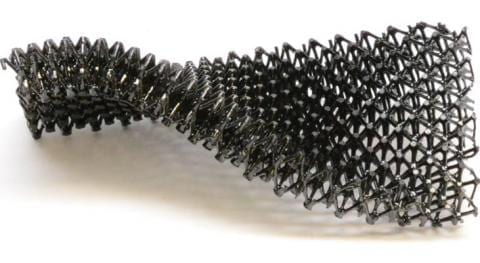

Despite having several useful properties like durability, use of ceramics in complex shapes has largely remained challenging task because of some flaws in the material that can leave the door open for catastrophic failures.

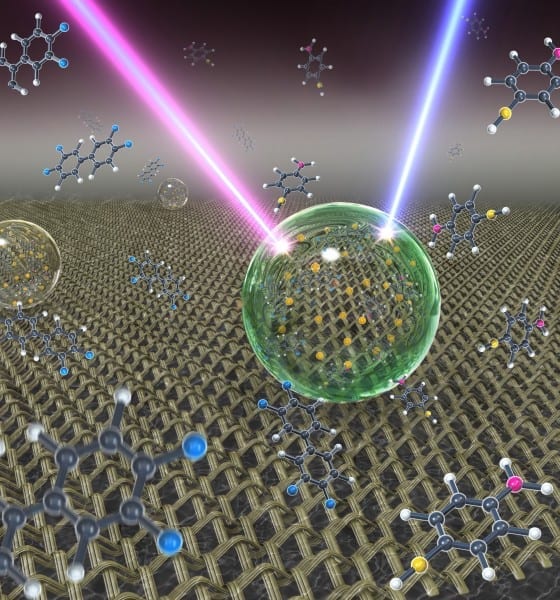

But, researchers at HRL Sensors and Materials Laboratory have managed to create 3D printing ceramics by combines numerous techniques that have already been in use. The breakthrough can help create complex and complicated structures that are very strong and can withstand temperatures of up to 1,700 degrees Celsius.

Dr. Tobias Schaedler, a senior scientist at the lab, said, “Our team surmounted the challenges inherent in ceramics to develop an innovative material that has myriad applications in a variety of industries. The resulting material can withstand ultrahigh temperatures in excess of 1700°C and exhibits strength ten times higher than similar materials.”

Unlike polymers and metals, ceramics are very difficult to process because they can’t be cast or machined easily. Thus, it limits the shapes that can be achieved with ceramics.

Further technical details of the research, which was funded by HRL and the U.S. Defense Advanced Research Projects Agency (DARPA), appeared in a recent edition of journal Science.

In other news NextBigFuture reported, HRL Laboratories, LLC, Malibu, California is a corporate research-and-development laboratory owned by The Boeing Company and General Motors specializing in research into sensors and materials, information and systems sciences, applied electromagnetics, and microelectronics.

HRL’s Senior Chemical Engineer Zak Eckel and Senior Chemist Dr. Chaoyin Zhou invented a resin formulation that can be 3D printed into parts of virtually any shape and size. The printed resin can then be fired, converting it into a high strength, fully dense ceramic. The resulting material can withstand ultrahigh temperatures in excess of 1700°C and exhibits strength ten times higher than similar materials.

In a statement provided to I4U, scientists have developed a new 3D printing technique that allows them to eliminate shortcomings of traditional ceramic processing and to create more strong and flawless ceramics

The material can withstand temperature in excess of 1,700 degree Celsius and scientists believe that it will soon be used in aerospace industry for building future spaceships and hypersonic aircrafts.

Read more: U.S. researchers hit ceramic 3D printing breakthrough

The Latest on: 3D printed ceramic parts

[google_news title=”” keyword=”3D printed ceramic parts” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: 3D printed ceramic parts

- Prodways & SINTX announce deep technical ceramic 3D printing partnershipon April 30, 2024 at 12:44 am

Advanced technical ceramic company SINTX Technologies has entered into a technical partnership and ceramic slurry supply agreement with Prodways.

- SINTX AND PRODWAYS AGREE ON CERAMIC SLURRY SUPPLY AND 3D PRINTING AGREEMENTon April 29, 2024 at 6:58 am

SINTX was an early pioneer of the ceramic 3D printing industry, successfully printing components beginning in 1998. The company invested in R&D for more than a decade - successfully growing its ...

- How 3D Printing can Help Fuel the South America Oil Boomon April 26, 2024 at 6:59 am

Charles R. Goulding and Andressa Bonafe discuss how South American countries can leverage 3D printing technology to bolster their positions as emerging players in the global oil and gas market.

- Magnus Metal wants to revamp the 4,000-year-old way metal parts are madeon April 18, 2024 at 6:00 am

Humans have cast metal parts in basically the same way for thousands of years: by pouring molten metal into a mold, often made of compacted sand and clay. There’s a reason this ancient method is used ...

- The redesigned 3D printer from Formlabs gets us one step closer to the Enterprise Replicatoron April 17, 2024 at 6:23 am

The Form 4 is modular, more precise, and five times faster than the previous generation. The Form 4 3D printer is modular, more precise, and five times faster than the previous generation.

- MIT Can 3D Print a Metal Chair in Minutes. Just Don’t Expect It to Look Niceon January 25, 2024 at 10:15 am

Creating an object one thin layer at a time is a time-consuming process, and although there are 3D printers that can create parts from metal, the printing ... found that ceramic was the best ...

- The 3D Printing Behind The Billion-Dollar Smile Businesson August 13, 2023 at 9:49 am

3D printer maker Formlabs launched the Form Auto in 2023 that automatically removes finished parts ... LightForce are 3D printed ceramic brackets customized to the shape and orientation ...

- Chinese scientists develop cutting-edge tech for 3D ceramic printing in the air to create complex engineering partson May 14, 2023 at 7:20 am

This cutting-edge method can construct ceramic parts at almost any angle, enabling the creation of shapes that were previously impossible for typical 3D printing techniques. Ceramics are widely ...

- DuPont Bets On Electronics 3D Printingon March 7, 2022 at 8:43 am

I have covered 3D ... printer that can process a much wider range of materials than many AM systems out there. One of its powers is the ability to magnetically align composite particles, such as ...

- 3D Printing Nuclear Reactors For Fun And Profiton June 8, 2020 at 12:50 am

In the nuclear power industry, these benefits haven’t gone unnoticed, which has led to 3D printed parts being developed ... the material (e.g. nylon, metal, ceramic or glass), but without ...

via Bing News