Satellite design doesn’t have to be rocket science

When you buy a mouse for your computer, removing the packaging is probably the hardest part of integrating it into your home system. Once you plug in the USB cable, you click on the mouse, and it just works. For it to “just work,” of course, a great many things have to happen in the background: Via the USB cable, the mouse’s circuitry receives power, initializes, and is recognized by the computer as a valid device. Then the driver software takes over, identifying the device as a mouse and not, say, a printer or a keyboard. Finally, a rapid succession of electrical messages traverses the cable, and these messages are translated into commands that then move the cursor smoothly across your computer screen. The fact that you don’t need to know any of this to operate a mouse is by design: The mouse’s computer chips and embedded software conceal the device’s complexity.

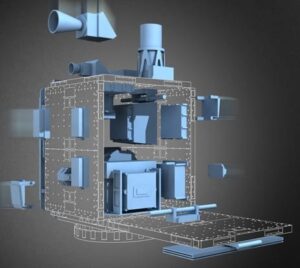

This was not an isolated case—indeed, it’s universal. So eight years ago, a few of us at the Air Force Research Laboratory (AFRL) set out to find a better way. Along with a small cadre of researchers from industry, government, and academia, we have been studying the example of the personal computer and “plug-and-play” concepts from other industries in search of lessons we could apply to the task of building better spacecraft. Traditionally, satellite designers strive to increase raw performance or system capabilities by turning to faster processors or more sophisticated sensors. But we took a very different approach, concentrating instead on slashing the time it takes to go from inception to launch. Our goal was, well, lofty: to build a working satellite in just six days.

We not only succeeded in the lab, we also laid the groundwork for others. Our plug-and-play concept is now being incorporated into several satellite projects, including a tactical battlefield spacecraft being developed by Northrop Grumman Corp. for the U.S. military. The basic architecture is also a perfect fit for spacecraft that carry an eclectic mix of instruments, such as weather and environmental monitoring satellites, and those that have an inherently modular design, such as communications satellites. And although our initial efforts have been aimed mainly at small satellites (that is, those weighing less than 450 kilograms), the plug-and-play architecture should work just as well regardless of the system’s size.

Meanwhile, parallel trends in satellite design and in manufacturing should make the adoption of plug-and-play satellites more palatable to the otherwise quite conservative aerospace industry. These include the enormous popularity of the miniature satellites known as CubeSats. Legions of college students and other space enthusiasts have worked on these tiny orbiters, in the process seeding the notion that spacecraft design need not be a high-overhead endeavor. The other development is 3-D printing, which allows quick production of three-dimensional objects directly from digital designs; embraced by the DIY crowd, this kind of rapid, on?demand manufacturing is also the perfect complement to plug-and-play satellite design.

via IEEE Spectrum – James C. Lyke

The Latest Streaming News: Plug-and-Play Satellites updated minute-by-minute