A wrench and hammer might be good for some building projects, but the nuts and bolts found in a standard garage toolbox definitely wouldn’t hit the nail on the head when it comes to constructing a 321-foot, 5.5 million-pound rocket.

That’s why engineers at NASA’s Michoud Assembly Facility in New Orleans are installing massive tools — one more than 170 feet tall — specifically designed and built to weld together pieces of the core stage of the Space Launch System (SLS) — NASA’s new heavy-lift rocket that will send humans to deep space destinations, including an asteroid and Mars.

“One of the challenges that we face in building this large core stage is to develop world-class tooling using modern manufacturing methods in an affordable way, while maintaining the scheduled first launch in 2017,” said Tony Lavoie, manager of the Stages Office at NASA‘s Marshall Space Flight Center in Huntsville, Ala. “This tool set that we’ve developed for Michoud to build the core stage is a perfect blend of those requirements and constraints.”

Six substantial welding tools will be used to handle assembly of the new cryogenic core stage on SLS. Suppliers worked with NASA and The Boeing Company of Huntsville over the course of a year to design and build the tools. Boeing is the prime contractor for the SLS Core Stage, including avionics.

The tools include:

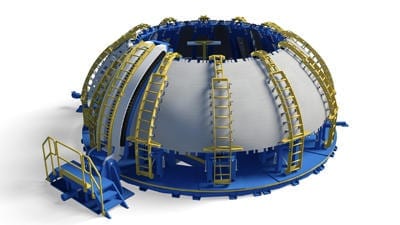

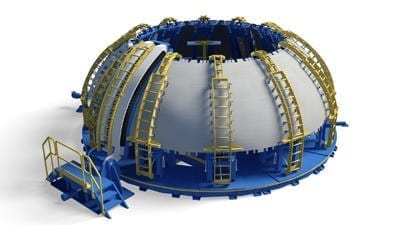

- The Circumferential Dome Weld Tool will be used to perform circumferential friction stir welds in the production of dome assemblies for the SLS core stage cryogenic tanks.

- The Gore Weld Tool will perform vertical conventional friction stir welds in the production of gore assemblies for the SLS core stage tanks. Gores are preformed aluminum alloy dome segments that are welded together to make the dome.

- The Circumferential Dome Weld and Gore Weld tools are special tooling for the Enhanced Robotic Weld Tool — used to make dome components for SLS.

- The Vertical Weld Center is a friction-stir-weld tool for wet and dry structures on the SLS core stage. It will weld barrel panels together to produce whole barrels for the two pressurized tanks, the Intertank, the Forward Skirt and the Aft Engine Section. It stands about three stories tall and weighs 150 tons.

- The Segmented Ring Tool will use a friction-stir-weld process to produce segmented support rings for the SLS core stage. The rings connect and provide stiffness between domes and barrels.

- The Vertical Assembly Center (VAC), where domes, rings and barrels will be joined together to complete the tanks or dry structure assemblies. The tool also will perform nondestructive evaluation on the completed welds. The VAC, measuring 170 feet tall and 78 feet wide, is one of the world’s largest welding tools. It is anticipated to be completed in 2014.

“It’s an exciting time to be a part of NASA’s team,” said Rick Navarro, Boeing operations manager at Michoud.

The Latest Bing News on:

Space Launch System

- LEGO NASA Artemis Space Launch System Set: What we know about release date, price, features, part count and designon April 27, 2024 at 1:26 pm

LEGO's upcoming Artemis Space Launch System set is a detailed replica of NASA's rocket system, offering a challenging build experience with its 3601 pieces. It is priced at $259.99 and set for release ...

- Boeing plans job cuts for SLS workers, NASA slowed Artemis launch scheduleon April 25, 2024 at 5:02 pm

Boeing confirmed Thursday that staffing changes are coming. The company employs 3,400 people in Huntsville. Boeing declined to say how many of those employees work on the SLS program and did not ...

- LEGO Artemis Space Launch System and Milky Way Sets Are Ready For Liftoffon April 25, 2024 at 7:28 am

At this point we know that the big LEGO drops for May 2024 are going to be the Star Wars Day sets, Despicable Me 4 sets, and the two space-themed sets that LEGO unveiled today – NASA Artemis Space ...

- Blast Off with LEGO's New NASA Artemis Space Launch System Seton April 25, 2024 at 5:23 am

Get ready to explore and build the NASA Artemis Space Launch System (SLS), which is a next-generation rocket that was designed to support the Artemis program, This NASA initiative was created to ...

- Lego reveals NASA Artemis rocket, Milky Way galaxy sets coming in Mayon April 24, 2024 at 5:00 pm

The toy company on Thursday (April 25) revealed its upcoming Lego Icons NASA Artemis Space Launch System and Lego Art The Milky Way Galaxy sets. Both will go on sale beginning May 15. From ...

- Space startups are licking their lips after NASA converts $11B Mars mission into a free-for-allon April 16, 2024 at 1:27 pm

Although NASA’s troubled Space Launch System heavy launch vehicle is perhaps the largest such project, to abandon it now would be to throw away a great deal, while preemptively opting for a ...

- Saturn MLV Would Have Been the Mother of All Space Rockets, Here It Goes Like It Never Didon April 15, 2024 at 12:51 am

Before the Space Launch System rocket of the Artemis program and SpaceX's Starship got here, the Saturn V rocket used in the Apollo Moon exploration program was humanity's largest and most ...

- Opinion: The day of the Columbia disaster still haunts meon April 13, 2024 at 11:01 pm

So, there was a lot of focus on security. But I was also thinking about the fragility of the space launch system. Engineers had been most recently vexed by a series of cracks in the shuttle’s ...

- Delta IV Heavy rocket launch from Cape Canaveral: How to stream space coverage on iPhone, TVon April 9, 2024 at 9:53 am

It was following the success of this flight that NASA’s Orion crew capsule flew on NASA’s Space Launch System (SLS) rocket, successfully demonstrating an uncrewed mission around the moon in 2022.

- Delta IV Heavy launch recap: Historic final rocket flight from Cape Canaveral, Floridaon April 9, 2024 at 5:53 am

Air Liquide confirms that a pump failure occurred on March 28 at its nitrogen plant supplying NASA’s Space Launch System (SLS). Air Liquide worked diligently with NASA to understand the ...

The Latest Google Headlines on:

Space Launch System

[google_news title=”” keyword=”Space Launch System” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Heavy-lift rocket

- Russia launches new Angara A5 heavy-lift rocket on 4th orbital test mission (photos)on April 18, 2024 at 8:00 am

The Angara A5 took off from the nation's Vostochny Cosmodrome for the first time, placing an experimental cubesat into low Earth orbit.

- New Russian heavy-lift rocket makes it into space after 2 failed launcheson April 12, 2024 at 9:17 am

Russia has developed a new rocket and a new launch site as it considers a lunar research program. After two aborted launches, the Angara-A5 was successfully test-launched.

- Russia launches a heavy-lift rocket from Far East after two previous attempts cancelledon April 11, 2024 at 3:25 am

Russia launched a new heavy-lift rocket from its Far East space complex Thursday after two failed attempts earlier this week.

- In Russia's Far East, a new heavy-lift rocket blasts off into space after two aborted launcheson April 11, 2024 at 2:25 am

Russia has successfully test-launched a new heavy-lift rocket from its Far Eastern space complex, a lift-off that comes after two aborted attempts earlier this week MOSCOW -- Russia on Thursday ...

- ULA launches its last Delta IV Heavy rocket for US spy agencyon April 10, 2024 at 7:17 am

The last of United Launch Alliance's Delta IV Heavy rockets lifts off the launchpad at Cape Canaveral Space Force Station, in Florida, on April 9, 2024. It carries a classified payload to orbit for ...

- Russia aborts second attempt to launch a heavy-lift rocket from Far Easton April 10, 2024 at 2:25 am

Russia's second attempt to test-launch a new heavy-lift rocket from its Far Eastern space complex was aborted on Wednesday. The launch of the Angara-A5 rocket from the Vostochny spaceport was canceled ...

- Russia cancels attempt to launch heavy-lift Angara-A5 rocketon April 10, 2024 at 2:06 am

Russian space officials again canceled an attempt on Wednesday to test launch a new heavy-lift rocket, the Angara-A5, from Vostochny cosmodrome. An earlier attempt on Tuesday was aborted two minutes ...

- PHOTO GALLERY: Marking the End of an Era, ULA Successfully Launches Final Delta IV Heavy Rocketon April 9, 2024 at 9:11 pm

The Delta program, spanning 60 years, came to a close with the launch of the final Delta IV Heavy rocket by United Launch Alliance (ULA) on April 9 at 12:53 p.m. EDT from Space Launch Complex-37 at ...

The Latest Google Headlines on:

Heavy-lift rocket

[google_news title=”” keyword=”heavy-lift rocket” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]