This time they are hoping to produce the technologies for a 21st-century revolution in clean energy.

IN THE 1970s researchers lounging on bean bags at Xerox’s Palo Alto Research Centre (PARC) churned out the inventions that would trigger the coming revolution in information technology. The computer mouse was born here, as were icons, windows, Ethernet networking and the laser printer. Today, although the bean bags are long gone and PARC was spun out as a subsidiary a decade ago, its researchers are once again experimenting with printing. This time they are hoping to produce the technologies for a 21st-century revolution in clean energy.

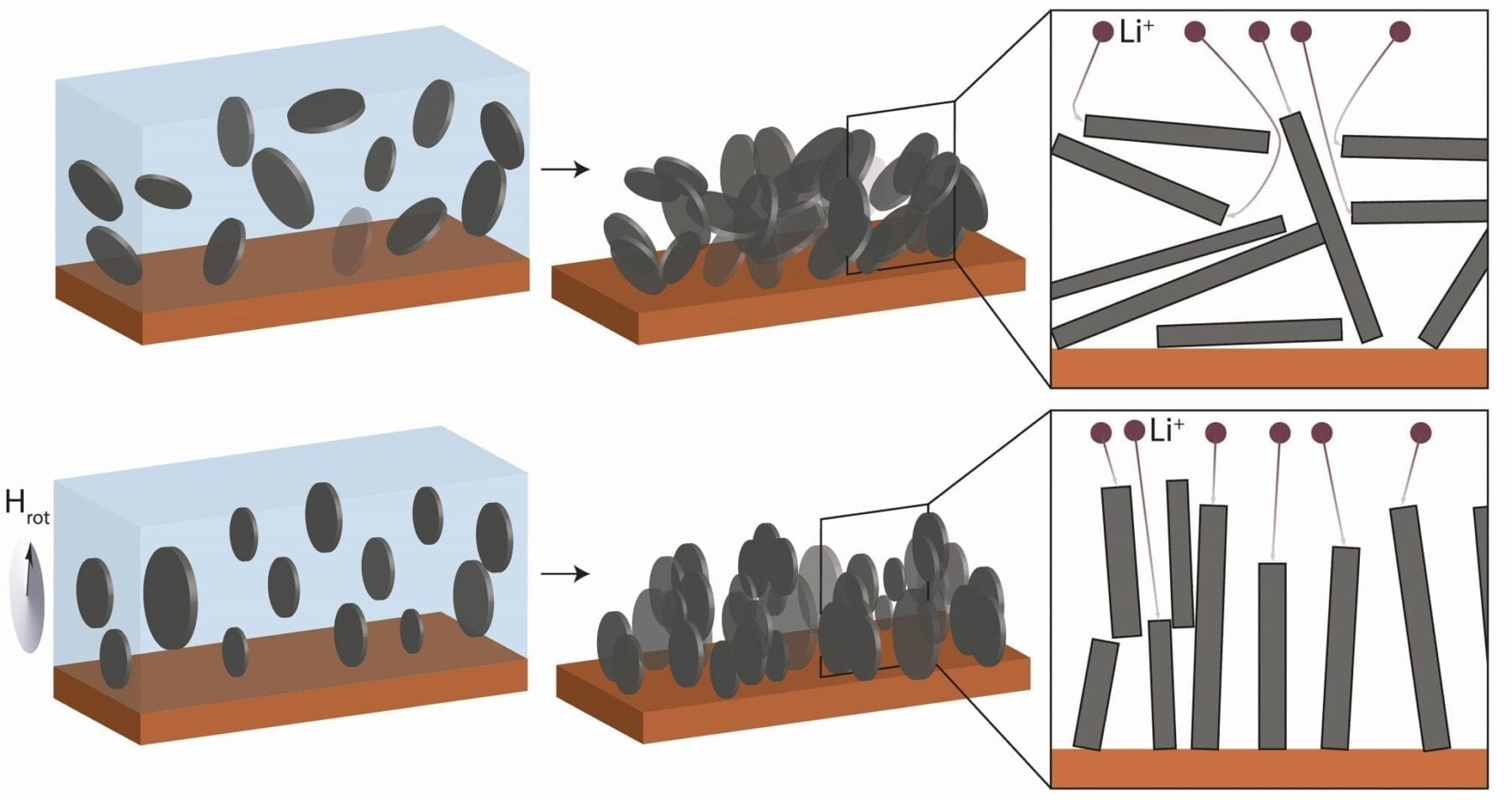

PARC’s Hardware Systems Laboratory is developing electric-vehicle lithium-ion batteries that can hold 20% more energy than traditional designs. Making a battery that can store more energy requires a larger cathode containing more lithium ions. However, the thicker the cathode, the slower the ions will move through it. This reduces the battery’s power, leading to sluggish acceleration.

PARC wants to evade this trade-off by constructing cathodes from two materials: one dense, and optimised for storage; the other porous, for the speedy transfer of charge. Wide storage regions would alternate with narrow conductive regions. That will enable a larger and more energy-dense battery to be constructed without sacrificing its power.

This basic idea has been understood for some time. The trick is building the regions small enough (about 100 microns across for the storage medium, and ten for the conductor). The cathode of a typical electric car’s battery would need tens of thousands of these interleaved fingers. Making such tiny features with precision would require photolithography, an expensive technology unsuitable for high-speed volume manufacturing of big batteries.

The PARC researchers’ solution, which would surely have impressed their free-thinking forebears, was inspired by striped toothpaste. In PARC’s new battery, the two materials are mixed with an organic material to form pastes and fed into a print head containing tiny channels and nozzles. The print head moves over a metal foil, extruding the pastes alongside one another, to create thin stripes. Drying the substrate removes most of the organic material, leaving a solid cathode. In tests against otherwise identical batteries sporting cathodes made of but one substance, the co-extruded rechargeables could store a fifth more energy. Scott Elrod, the laboratory’s boss, says that PARC is now discussing how to test the new battery with firms that might eventually manufacture it.

The Latest Bing News on:

Batteries

- Investing In The Evolution Of Batteries- An Electrifying Journey - Financial News Mediaon May 1, 2024 at 3:00 pm

Investorideas , a go-to investing platform covering battery stocks releases a news report drilling down on developments for better batteries, featuring KULR Technology Group, Inc. (NYSE American: KULR ...

- University of Sheffield works to develop batteries for Africaon May 1, 2024 at 1:23 pm

Engineers have been developing longer-life batteries to help communities in Africa. The University of Sheffield said more than 740 million people around the world do not have access to electricity, ...

- Power up your savings with this $10 pack of Duracell batteries — it's nearly 60% offon May 1, 2024 at 7:49 am

If you're like the rest of us, batteries are a constant need in your home. The thing is, you don't know you need them until you're out and there's not a single battery to be found anywhere in the home ...

- Ecobat and Nissan Partnership to Give Used EV Batteries a Second Lifeon April 30, 2024 at 11:54 pm

Used electric vehicle batteries will be given a second life in the UK, thanks to a new partnership between Nissan and Ecobat Solutions UK. The two companies are working together to investigate how EV ...

- Ecobat and Nissan Partnership to Give Used EV Batteries a Second Life Beyond the Caron April 30, 2024 at 4:17 pm

Used electric vehicle batteries will be given a second life in the UK, thanks to a new partnership between Nissan and Ecobat Solutions UK Ltd. The two ...

- Lithium Faces Challenge From Sodium Batterieson April 30, 2024 at 3:00 pm

Lithium-ion has been the dominant rechargeable battery technology for years, but the strong charge and discharge capacities from Sodium batteries could make a difference in the energy storage business ...

- Energizer’s new batteries warn parents if children swallow themon April 29, 2024 at 6:40 am

In the wake of a report that warned more children were swallowing small batteries, Energizer is taking steps to make them safer. Category : News ...

- Sodium Batteries From Michigan to Challenge Lithium’s Gripon April 29, 2024 at 5:00 am

Natron Energy Inc. will unveil what it bills as the first full-scale plant in the US for making sodium-ion batteries on Monday. The plant situated near Michigan’s western shore has already started ...

- Bin fire in Cornwall after batteries not recycledon April 26, 2024 at 11:48 pm

People in Cornwall are being asked to remember to recycle batteries after a fire started on a rubbish collection vehicle. Cornwall Council said smoke was seen coming from the back of the lorry while ...

- Lowe’s Will Give You Two Free Batteries and a Charger When You Buy This DeWalt Impact Wrenchon April 26, 2024 at 8:27 am

Lowe’s offer saves you $129, which is a decent chunk of change you can put toward other cordless power tools. Batteries are a notoriously expensive part of building out your toolkit, so getting a free ...

The Latest Google Headlines on:

Batteries

[google_news title=”” keyword=”batteries” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Energy storage

- CPS Energy closes $785 million deal for 1.7 GW natural gas fleeton May 1, 2024 at 3:18 pm

Through the deal, CPS Energy has acquired all assets associated with the 897 MW Barney Davis and 635 MW Nueces Bay natural gas-fired generation facilities.

- CPS Energy closes on $785 million deal to acquire natural gas plants in Corpus Christi, Laredoon May 1, 2024 at 2:52 pm

The deal will add 1,710 megawatts of power to the CPS Energy generation porfolio. The utility said this will help add critical capacity and retire older gas units.

- Why energy storage is key to global renewable goalson May 1, 2024 at 2:52 pm

G7 environment ministers committed on Tuesday to ramp up the production and deployment of battery storage technology, an essential component for increasing renewable energy and combating climate ...

- Energy Storage: A New Asset Class Buyers Of Power Should Consider Investing Inon May 1, 2024 at 8:00 am

Investing in energy storage doesn’t just provide a pathway for reducing carbon emissions; it’s also a pathway for potential savings on electricity and energy costs.

- Duke Energy completes upgrades to pumped storage facility in South Carolinaon May 1, 2024 at 4:59 am

Duke Energy finished upgrades to the four units at the Bad Creek pumped storage facility in Salem, S.C., adding 320 megawatts of carbon-free energy to the company’s system. Pumped storage hydro plants ...

- Australian energy storage tender attracts 19 GW of proposalson April 30, 2024 at 5:00 pm

The Victoria and South Australia tender was seeking bids for energy generation and storage projects with up to 600 MW / 2,400 MWh of dispatchable capacity that will be operational before the end of ...

- “AI Energy” & Energy Storage: A $40 Trillion Market Disruptoron April 30, 2024 at 11:00 am

The global energy storage market is set to add 50 gigawatts of capacity in 2024, all thanks to artificial intelligence. We call it AI Energy.

- Nevada put big battery energy storage where a coal plant used to beon April 29, 2024 at 4:31 pm

Nevada utility NV Energy's largest battery energy storage system sits on a former coal-fired power plant site and will save customers a lot of money.

- Battery Storage Is the No. 1 Energy Investment Playgroundon April 29, 2024 at 9:00 am

Battery storage was the fastest-growing energy technology in the power sector in 2023, with deployment more than doubling year-on-year ...

- Energy storage plant could power 124k homeson April 29, 2024 at 4:15 am

The storage system would be built off Foxhounds Lane in Southfleet, near Gravesend, and store enough energy to power more than 124,000 homes, planning documents say. EcoDev said t ...

The Latest Google Headlines on:

Energy storage

[google_news title=”” keyword=”energy storage” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]