If perfected, it could lead to desktop manufacturing plants that “print” the circuitry for a wide array of electronic devices

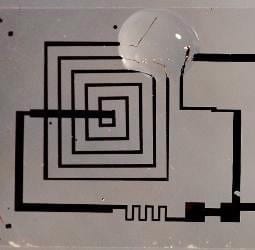

Under a microscope, four slivers of silicon — electronic circuits called chiplets — perform an elaborate, jerky dance as if controlled by a hidden puppet master. Then on command, they all settle with pinpoint accuracy, precisely touching a pattern of circuit wires, each at just the right point of contact.

The technology, on display at Xerox’s Palo Alto Research Center, or PARC, is part of a new system for making electronics, one that takes advantage of a Xerox invention from the 1970s: the laser printer.

If perfected, it could lead to desktop manufacturing plants that “print” the circuitry for a wide array of electronic devices — flexible smartphones that won’t break when you sit on them; a supple, pressure-sensitive skin for a new breed of robot hands; smart-sensing medical bandages that could capture health data and then be thrown away.

Today’s chips are made on large wafers that hold hundreds of fingernail-sized dies, each with the same electronic circuit. The wafers are cut into individual dies and packaged separately, only to be reassembled on printed circuit boards, which may each hold dozens or hundreds of chips.

The PARC researchers have a very different model in mind. With financing from the National Science Foundation and from Darpa, the Pentagon’s Defense Advanced Research Projects Agency, they have designed a laser-printer-like machine that will precisely place tens or even hundreds of thousands of chiplets, each no larger than a grain of sand, on a surface in exactly the right location and in the right orientation.

The chiplets can be both microprocessors and computer memory as well as the other circuits needed to create complete computers. They can also be analog devices known as microelectromechanical systems, or MEMS, that perform tasks like sensing heat, pressure or motion.

The new manufacturing system the PARC researchers envision could be used to build custom computers one at a time, or as part of a 3-D printing system that makes smart objects with computing woven right into them.

The technology is still in the future. The researchers are years from simultaneously placing tens or hundreds of thousands of circuits accurately in a fraction of a second. And they acknowledge that this would be only the first step in designing a commercially viable system.

Still, if the PARC researchers are successful, they will have thrown out 50 years of Silicon Valley conventional wisdom.

A related but simpler technology was pioneered by Alien Technology, a maker of RFID tags in Silicon Valley. Called Fluidic Self Assembly, it is based on suspending small integrated circuits called “nanoblocks” in a fluid and then flowing them over a surface where they drop into tiny holes of corresponding shapes.

Both approaches reverse a five-decade long tradition of making computers faster and more powerful by doubling every two years the number of transistors squeezed onto fingernail-sized computer chips.

The emerging printing technology poses a heretical idea: Rather than squeezing more transistors into the same small space, why not smear the transistors across a much larger surface?

Moreover, the research could have tremendous economic consequences — feeding the emergence of a new digital era in manufacturing, much as laser printing transformed publishing three decades ago.

The Latest Bing News on:

Micro-manufacturing

- KSC receives federal funding to bolster precision manufacturingon April 26, 2024 at 8:29 am

KSC will use the funding to offer additional courses for college credit, non-credit training, employer-based training, micro-credentials, and interdisciplinary applied research. The release says there ...

- Electronic Manufacturing Services Market Poised to Achieve Remarkable Growth, Exceeding US$ 859.96 Billion by 2033on April 26, 2024 at 7:49 am

Electronic Manufacturing Services Market is set to reach US$ 859,959.3 Million by 2033 at a CAGR 4.7% amid growing demand for consumer electronics | Data by FMI ...

- Rocklin Manufacturing celebrates 90th anniversaryon April 25, 2024 at 9:28 am

After the war, Rocklin began manufacturing portable products, which led to the invention of its Rocklinizer Carbide Applicator and MoldMender Micro Welder. In recent years, the company has formed ...

- Investing in Tamil Nadu: Manufacturing Outlook and Opportunitieson April 23, 2024 at 5:27 am

India Briefing profiles the manufacturing sector in the southern state of Tamil Nadu, and explores its appeal for foreign investment.

- Advanced Micro Devices Inc AMDon April 22, 2024 at 4:59 pm

AMD has gained market share in the PC CPU market as Intel’s manufacturing prowess has hit several road bumps in recent years. Despite AMD’s recent share gains, Intel remains the industry ...

- Centre focuses on transforming India into a leading destination for manufacturing and services: Sitharamanon April 20, 2024 at 3:56 am

Union Finance Minister Nirmala Sitharaman on Saturday said the Centre has tailored policies to make India an attractive destination for manufacturing and services, and the aim was to produce not just ...

- Western Technical College looks to give students access to manufacturing jobs after receiving granton April 17, 2024 at 8:24 pm

Senator Tammy Baldwin announced that Western Technical College, in collaboration with eight other colleges in the Wisconsin Technical College System, received a $5.7 million grant to help ...

- Missouri Coalition for the Environment awards $19K in micro-grants to local farmers, small businesseson April 15, 2024 at 4:50 pm

Among the recipients is a community garden in the city’s College Hill neighborhood that was vandalized but was unable to pay the rental fee for equipment to repair its plots.

- Intel Just Revealed Why It Can't Split From Its Manufacturing Model and Why the Stock Is a Hold at Beston April 15, 2024 at 1:10 am

Steep losses and an imprecise model for future profitability make the chipmaker a tough stock to own right now.

- Best Places to Work 2024: No. 5 Processor: MTD Micro Moldingon April 14, 2024 at 11:00 pm

Do you have an opinion about this story? Do you have some thoughts you'd like to share with our readers? Plastics News would love to hear from you. Email your letter to Editor at ...

The Latest Google Headlines on:

Micro-manufacturing

[google_news title=”” keyword=”micro-manufacturing” num_posts=”10″ blurb_length=”0″ show_thumb=”left”] [/vc_column_text]The Latest Bing News on:

Desktop manufacturing plants

- 'America manufacturing is back': Idaho Gov. Little, Boise mayor join President Biden for $6.1 billion Micron granton April 25, 2024 at 9:55 am

Idaho Gov. Little and Boise Mayor McLean are alongside President Biden in NY as he announces the multibillion grant for Boise-based Micron's semiconductor plants.

- As Biden celebrates computer chip factories, voters wait for the promised production to starton April 25, 2024 at 2:11 am

For decades, voters have heard politicians pledging a manufacturing boom without much to show for it. Factory employment peaked in the late 1970s and has steadily drifted downward because of ...

- UAFS plans to add manufacturing degree programon April 22, 2024 at 3:54 pm

The University of Arkansas at Fort Smith plans to add a new bachelor’s degree in smart manufacturing by as soon as Fall 2025. The new effort will be part ...

- Questions on semiconductor chip plants with power usage as state pushes climate planon April 18, 2024 at 6:13 pm

On Your Side found out there are also power usage concerns as the state seeks to transition to full electrification of homes and vehicles.

- Micron Wins $6.1B CHIPS Grant To Build Complex Of Computer Chip Plantson April 18, 2024 at 12:52 pm

The nation's largest memory chipmaker is poised to win billions in funding to boost U.S. semiconductor manufacturing.

- US to Provide $6.1 Billion for Micron Technology Chip Plantson April 18, 2024 at 7:11 am

The Biden administration has reached an agreement to provide $6.1 billion in government support for Micron Technology to produce advanced memory computer chips.

- US will provide $6.1 billion to Micron Technology for chip plants in NY and Idaho, Schumer sayson April 18, 2024 at 3:24 am

The Biden administration has reached an agreement to provide $6.1 billion in government support for Micron Technology to produce advanced memory computer chips in New York and Idaho.

- US Senate Secures $6.1 Billion for Micron Technology Chip Plants, Boosting Manufacturing Sector in NY, Idahoon April 17, 2024 at 10:10 pm

The project is poised to become a cornerstone of technological innovation, positioning the United States as a leader in semiconductor manufacturing.

- Micron scores $6.1 billion under CHIPS & Science Act to build mega-fab plant in Clayon April 17, 2024 at 2:40 am

The mega-fab plant is expected to be a project that ... The company plans to build a “clean-room” space for manufacturing computer chips that will cover about 2.4 million square feet, the ...

- Biden administration agrees to provide $6.4 billion to Samsung for making computer chips in Texason April 15, 2024 at 1:31 pm

The Biden administration has reached an agreement to provide up to $6.4 billion in direct funding for Samsung Electronics to develop a computer chip manufacturing and research cluster in Texas.

The Latest Google Headlines on:

Desktop manufacturing plants

[google_news title=”” keyword=”desktop manufacturing plants” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]