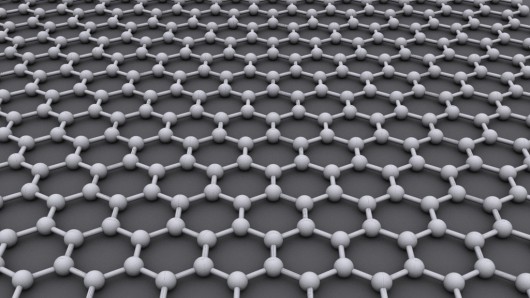

There’s no doubt that the discovery of graphene is one sweet breakthrough.

The remarkable material offers everything from faster, cooler electronics and cheaper lithium-ion batteries to faster DNA sequencing and single-atom transistors. Researchers at Rice University have made graphene even sweeter by developing a way to make pristine sheets of the one-atom-thick form of carbon from plain table sugar and other carbon-based substances. In another plus, the one-step process takes place at temperatures low enough to make the wonder material easy to manufacture.

Zhengzong Sun, a fourth-year graduate student in the lab of Rice chemist James Tour, found that depositing carbon-rich sources on copper and nickel substrates produced graphene in any form he desired, including single-, bi- or multiplayer sheets. Sun and his colleagues also found that the process adapts easily to producing doped graphene, which allows the manipulation of the material’s electronic and optical properties – an important factor in making switching and logic devices using the material.

For pristine graphene, Sun started with a thin film of poly (methyl methacrylate) (PMMA) – better known as Plexiglass – spun onto a copper substrate that acted as a catalyst. Under heat and low pressure, hydrogen and argon gas was flowed over the PMMA for 10 minutes, reducing it to pure carbon and turning the film into a single layer of graphene. Sun was able to control the thickness of the PMMA-derived graphene by changing the gas-flow rate.

Sugar, sugar

When he turned to other carbon sources, including a fine powder of sucrose – aka table sugar – is when things got interesting, says Sun. “We thought it would be interesting to try this stuff,” he said. “While other labs were changing the metal catalysts, we tried changing the carbon sources.”

Sun put 10 milligrams of sugar (and later fluorene) on a square-centimeter sheet of copper foil and subjected it to the same reactor conditions as the PMMA. It was quickly transformed into single-layer graphene. Sun said he had expected defects in the final product, given the chemical properties of both substances (a high concentration of oxygen in sucrose, five-atom rings in fluorene); but he found potential topological defects would self-heal as the graphene formed.

“As we looked deeper and deeper into the process, we found it was not only interesting, but useful,” Sun said.