“remarkable electronic properties”

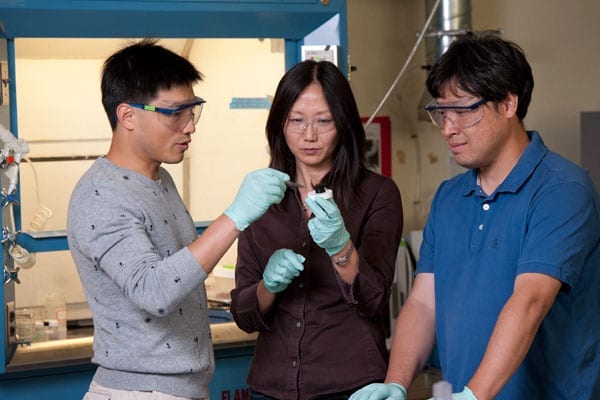

The Jell-O-like material, from the labs of Stanford professors Yi Cui and Zhenan Bao, may have applications in areas as widespread as energy storage, medical sensors and biofuel cells.

Stanford researchers have invented an electrically conductive gel that is quick and easy to make, can be patterned onto surfaces with an inkjet printer and demonstrates unprecedented electrical performance.

The material, created by Stanford chemical engineering Associate Professor Zhenan Bao, materials science and engineering Associate Professor Yi Cui and members of their labs, is a kind of conducting hydrogel – a jelly that feels and behaves like biological tissues, but conducts electricity like a metal or semiconductor.

That combination of characteristics holds enormous promise for biological sensors and futuristic energy storage devices, but has proven difficult to manufacture until now.

The research appears this month in the journal PNAS.

Printing Jell-O

Bao and Cui made the gel by binding long chains of the organic compound aniline together with phytic acid, found naturally in plant tissues. The acid is able to grab up to six polymer chains at once, making for an extensively cross-linked network.

“There are already commercially available conducting polymers,” said Bao, “but they all form a uniform film without any nanostructures.”

In contrast, the new gel’s cross-linking makes for a complex, sponge-like structure. The hydrogel is marked with innumerable tiny pores that expand the gel’s surface area, increasing the amount of charge it can hold, its ability to sense chemicals, and the rapidity of its electrical response.

Still, the gel can be easily manipulated. Because the material doesn’t solidify until the last step of its synthesis, it can be printed or sprayed as a liquid and turned into a gel after it’s already in place – meaning that manufacturers should be able to construct intricately patterned electrodes at low cost.

“You can’t print Jell-O,” said Cui. “But with this technique, we can print it and make it Jell-O later.”

via Stanford University – Max McClure

The Latest Streaming News: electrically conductive gel updated minute-by-minute