via Fraunhofer

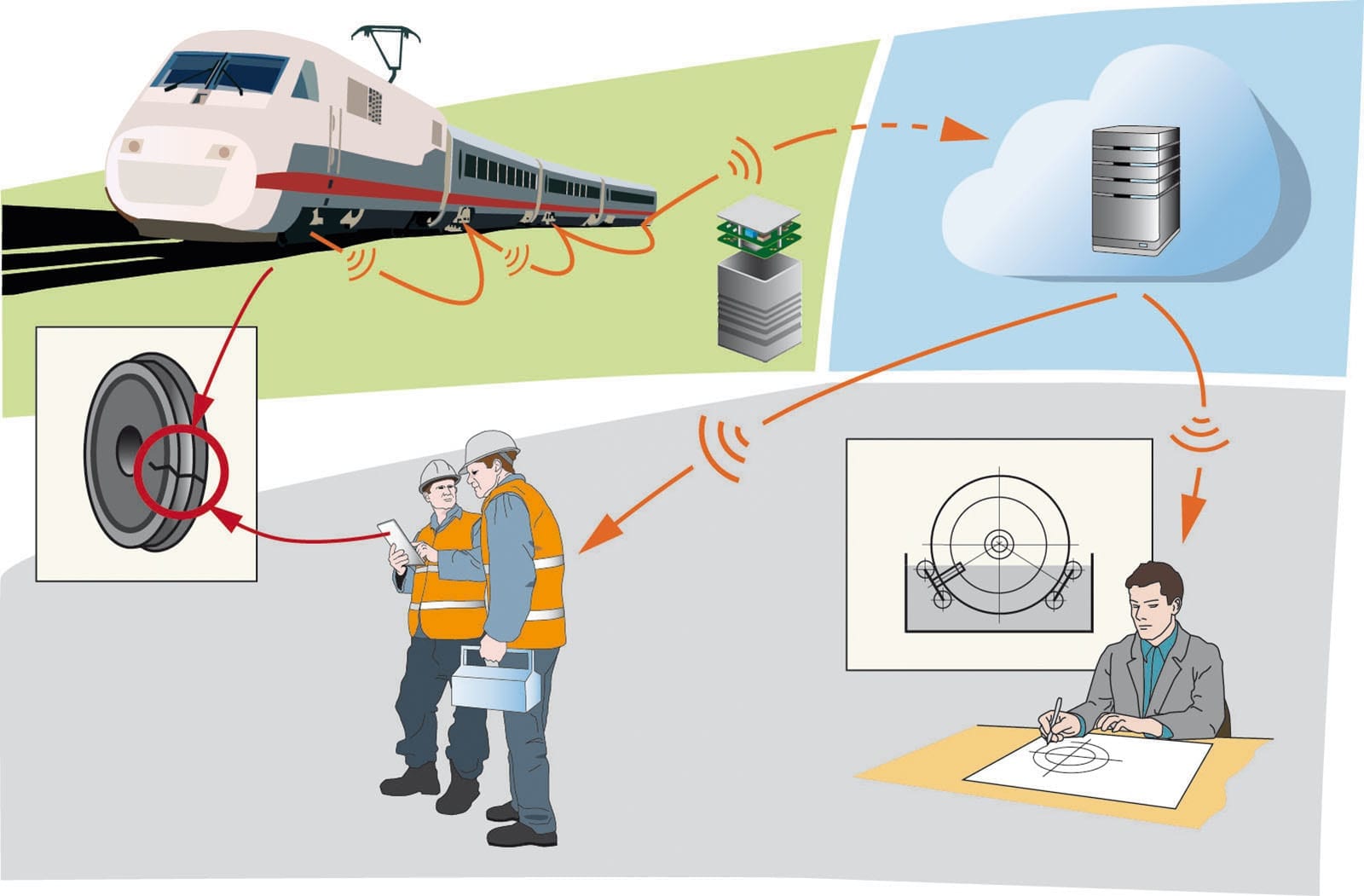

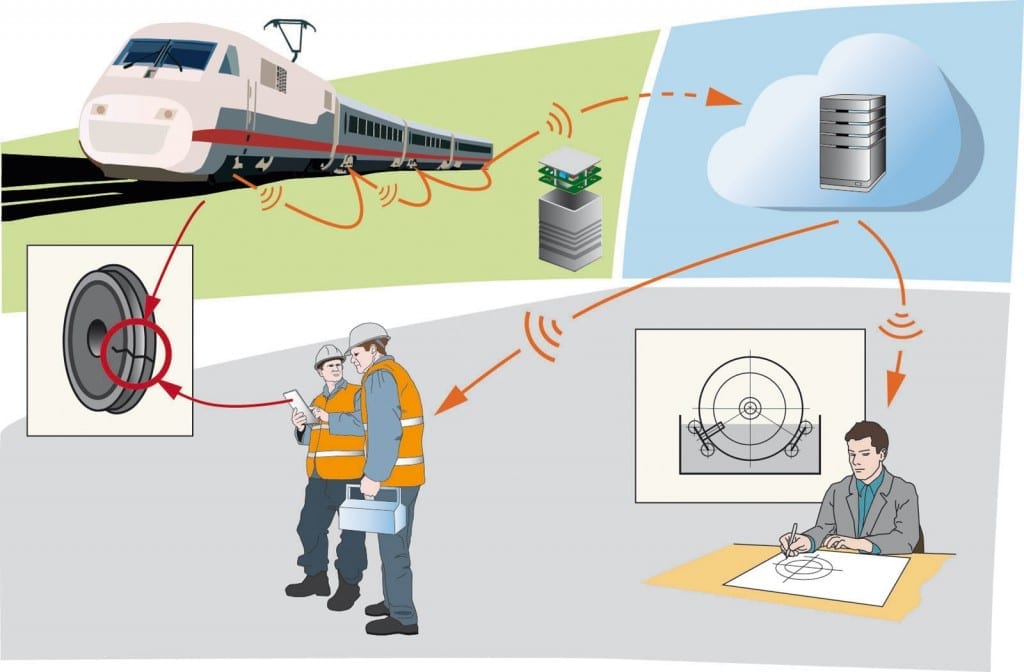

A new kind of human-machine communication is to make it possible to detect damage to rail vehicles before it’s too late and service trains only when they need it – all thanks to a cloud-supported, wireless network of sensors.

A train running on damaged wheels could easily be heading for serious trouble. This is why German national rail corporation Deutsche Bahn continuously monitors the wheelsets of its intercity express trains – a process that costs a considerable amount of time and money. Researchers at the Berlin-based Fraunhofer Institute for Reliability and Microintegration IZM are collaborating with industry partners to develop a solution that ensures a great safety while reducing effort and cost. “We want to root out any damage early on and move away from maintenance at set intervals in favor of condition-based maintenance,” explains Dr. Michael Niedermayer, microsystems engineer and head of the IZM’s Technology-Oriented Design Methods working group. He is also project coordinator for “Mobile Sensor Systems for Condition-Based Maintenance,” or MoSe for short.

Seamless monitoring

It’s all based on a cloud-supported, wireless network of sensors. Every axle and undercarriage on a train is fitted with small radio sensors, which collect data on the condition of wearing parts. These data are then transferred to the online maintenance cloud, where the measurement and analysis data are encrypted and stored ready for use. The sensors can detect even the tiniest scratch on a ball bearing. As Niedermayer says, “Here we have sensor nodes that can capture even the slightest variations in vibration. We call this in-depth diagnosis.” As a result, repairs can be made before anything works its way loose and causes damage.

“What’s remarkable about this approach is that it allows everything to be monitored with the train in service, rather than having to inspect it at the rail yard. And in any case, visual checks are not 100 percent reliable,” says Manfred Deutzer from project partner Deutzer Technische Kohle GmbH. Although there are wired sensors out there that can be used to examine rail vehicle chassis for wear and tear, these fail to match the high diagnostic quality standards the MoSe developers are striving for.

Read more . . .

The Latest on: Rail transport safety

[google_news title=”” keyword=”Rail transport safety” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Rail transport safety

- Federal government moves to push back possible rail strikeon May 10, 2024 at 6:52 am

The federal government is moving to push back the start of a possible strike by railway workers at Canadian National Railway (CN) and Canadian Pacific Kansas City (CPKC), an official said on Friday.

- Construction to begin on $3bn UAE to Oman train network; Hafeet Rail to transport passengers from Abu Dhabi to Sohar in 100 minuteson May 10, 2024 at 4:12 am

Construction will soon begin on a $3bn UAE to Oman rail network. The Hafeet Rail line will transport up to 400 passengers at a time from Abu Dhabi in the UAE to Sohar in Oman in 100 minutes, with top ...

- Cheating and retaliation? Houston should worry about Union Pacific’s safety culture. | Editorialon May 7, 2024 at 4:00 am

The federal railroad administration is suspending a safety assessment after it said it discovered coaching and intimidation of employees at Union Pacific.

- Agency Says Union Pacific Interfered in Safety Probeon May 2, 2024 at 8:38 am

Employees were coached and threatened as Federal Railroad Administration inspected the 23-state rail network after derailments, the agency says.

- Government needs to unbundle NRC for rail transport efficiency – Atagubaon April 27, 2024 at 7:01 pm

Chief Executive Officer of Bethlehem Rail Infrastructure Ltd in London and Chairman of the Rail Work Group of the Nigerian Economic Summit Group, Rowland Ataguba, speaks about rail business in Nigeria ...

- Guards to strike over rail safetyon April 24, 2024 at 5:00 pm

Members of the Rail Maritime and Transport union at 12 rail operators ... "Eight companies have already signed up to restore the guard's proper safety role to the rulebook, and there is no earthly ...

- Comprehensive guide to rail monitoring solutionson April 17, 2024 at 10:24 am

In the dynamic world of rail transport, ensuring the safety and efficiency of rail operations is paramount. Rail monitoring solutions play a crucial role in achieving this goal by providing critical ...

- Train Station: Rail Transporton April 7, 2024 at 12:54 pm

Manage your station, earn resources by managing transport of passengers and gain various materials with freight trains. Use them to build up your train station and to purchase more passenger and ...

- Minor in Rail Transportationon March 23, 2024 at 5:36 am

The Rail Transportation minor combines specific and multi-disciplinary class requirements. Take courses geared toward the rail industry and engineering. Also learn logistics, management, leadership, ...

- Biden admin quietly reverses Trump-era rule, bans transporting fossil fuels by trainon September 5, 2023 at 6:27 am

The Biden administration quietly rescinded a Trump-era regulation allowing companies to transport liquefied natural gas (LNG) via rail in a victory for environmental groups. In a federal filing ...

via Bing News