Universal Robot’s technology has been hailed “the world’s most innovative robot” by the International Federation of Robotics and IEEE (www.ieee.org).

Crucially, the technology can be used without guarding, so in collaboration with people; is aimed at small and medium enterprises and is already commonly used in machine/machine tool tending in Europe – but not yet in the UK (RA Rodriguez, 01462 670044).

Indeed, according to the Denmark-headquartered company’s Kristian Hulgard, area sales manager for Scandinavia and UK, some 60% of applications for the Universal Robots’ technology are in machine tending – the company has around 1,600 installations. According to Mr Hulgard, UK cost for a functioning installation is put at around £30,000 – “Better than half the price of a typical alternative robotic solution.”

Universal Robots was founded in 2005 by Esben Østergaard, now chief technology officer, with the declared goal of making robots accessible to small and medium-sized enterprises. The company offers two products – UR5 and UR10, with 5 kg and 10 kg handling capacity respectively (steel weighs around 8 g/cm3, so 625 [ie 5 by 40 cm] or 1,250 cm3 of steel [ie 10 by 40 cm]). The robots have two key elements that make them a safe, lower cost bet.

First, instead of expensive sensor technology, they employ a unique and patented technology to measure electrical current in joints to determine force and movement. Related to this is the second capability, which is to operate with no safety guarding. As soon as a person comes into contact with the robot arm and a force of at least 150 Newton is exerted (just over 15 kg), the robot arm will automatically stop. Importantly, however, companies must still carry out a risk assessment, stresses Mr Hulgard, adding that some 20% of installations do feature guarding of some sort.

MOBILE, SPEEDY SET-UP

Additional key features relate to mobility and programmability. The robots weigh as little as 18 kg, enabling them to be easily moved. Assuming that tasks have already been programmed and that there is some sort of ‘zero point’ location device to repeat accurate positioning, Mr Hulgard says: “It is only necessary to undo four bolts, relocate the robot and secure it. That can be done in 10 minutes.” And location can be on the floor, or on the front or side of the machine, he adds, the latter allowing manned access from the front, for example.

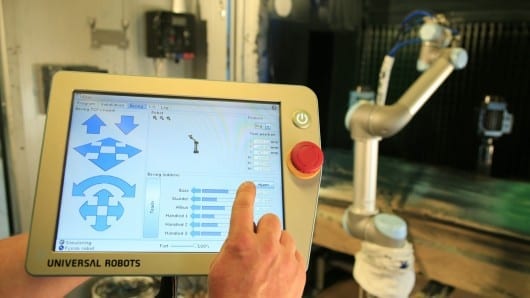

On programming, Mr Østergaard offers: “We decided to make programming intuitive by developing a graphical user interface, combined with a ‘teaching function’, allowing the user to simply grab the robot arm and show it how a movement should be performed. The robot can be integrated into any production process very quickly. Our experience shows this is generally done in a few hours.”

via Machinery – Andrew Allcock

The Latest Streaming News: Robots Work Safely With Humans updated minute-by-minute

Bookmark this page and come back often

Latest NEWS

Latest VIDEO