What is needed to adapt to the changing needs of life science researchers?

Until now, life science researchers had a narrow set of expectations for automation systems. The main focus of laboratory automation providers has been to develop liquid handling systems for high-throughput workflows processing very large samples numbers, primarily in screening laboratories. In this model all samples go through the same protocol, usually confined to a small number of simple steps, such as serial dilutions or simple plate-to-plate liquid transfers. While effective in these instances, the changing needs of life science research caused scientists to rethink automation and expect more capabilities and easier access.

Researchers continue to want high throughput, but they also want to improve data quality and translate it into shortened research timelines and reduced costs. Driven by the need to produce high-quality data in a high-throughput environment, researchers look to reduce manual intervention and automate workflows from sample preparation phase through data analysis.

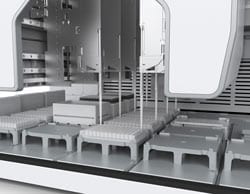

Highly flexible systems that facilitate integration of multistep processes and extend automation to more steps in the workflow can satisfy this new expectation. Industry responded to this need with recent introductions that make it possible to extend the use of automation to a wide range of life science assays and workflow steps, increasing access and allowing laboratory personnel to craft their own flexible automation solutions. Workflows can now benefit from flexibility, modularity, and integration so that a finite set of well-designed tools can be linked together by a broader group of laboratory personnel in order to tackle complex, multistep processes.

The benefit of introducing greater flexibility is very apparent in some of the most common laboratory applications. For example, speeding up sample preparation for next-generation sequencing and liquid chromatography-mass spectrometry allows scientists and laboratory personnel to employ sensitive and sophisticated techniques on medium to large sample numbers, while maintaining the highest levels of data integrity. Some factors driving this trend are the need to gain information earlier in the drug discovery process in order to reduce costs. It is a great advantage to run primary and secondary assays in parallel to shorten the overall timeline and reduce risks when choosing candidate compounds to pursue in later development stages. As a result, it is possible to advance candidates based on broader criteria, and thus increase the likelihood of success down the road. Beyond raising throughput in these instances, automation also improves reproducibility in complex multistep protocols by reducing the likelihood of random execution errors.

Automation flexibility can be improved with features that address significant bottlenecks impacting the speed of the overall process. For example, the ability to integrate multiple instruments frees scientists from individually defined solutions and enables flexible, modular options that can be modified based on existing laboratory instrumentation and changing experimental conditions. Second, the software driving the instrumentation should reflect the user’s perspective, rather than the traditional instrument focus, as this makes it easier for laboratory personnel to transfer their methods and protocols directly into automated solutions.

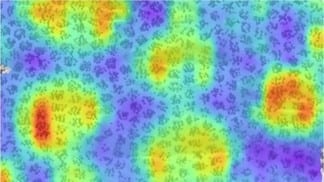

With regard to liquid handling, two key features that greatly increase the flexibility of an instrument include the pipetting head and the presence of robotic arms. Incorporating a multispan pipettor with truly independent x- and y-axis variability (Figure 1) makes it possible to move beyond the confines of high-density formats to a wide variety of commercially available vials, tubes, and plates, including types that are assay specific, such as Maldi and Caco-2 plates. While many automation systems incorporate robotic arms either as part of the main system or as add-ons, their functionality varies. An ideal robotic arm should have the finesse and articulation necessary to carry out critical assay steps on deck, such as the assembly of vacuum manifolds. It should also reach well off deck to pass plates to detectors and incubators in order to integrate complete workflows and reduce bottlenecks caused by a reliance on manual intervention. The need for increased flexibility necessitates an expansion of modularity to key components of the instrument, such as the use of individual pipetting cards and easy-to-move on-deck accessories.

The Latest Bing News on:

Rethinking Automation

- The Integration of Generative AI in RegTech: Rethinking Regulatory Complianceon May 8, 2024 at 10:09 am

The rapid expansion of the RegTech market is fueled by the integration of advanced technologies like Generative AI (GenAI). As regulatory environments ...

- Rethinking Atenolol as a First-Line Antihypertensiveon May 5, 2024 at 5:00 pm

The β-blocker atenolol is used widely as a first-line treatment for hypertension and as a reference drug in clinical trials. Prompted by a finding that the angiotensin-receptor blocker losartan ...

- Rethinking the Department of Homeland Securityon April 30, 2024 at 5:00 pm

Rethinking the Department of Homeland Security. The report is a product of a nonpartisan Task Force established by CSIS and the Heritage Foundation to examine what changes might be made to advance an ...

- Rethinking automation in the age of artificial intelligenceon April 28, 2024 at 7:40 pm

The new automation mindset cultivates plasticity within companies, encouraging continuous learning, evolution, and adaptation.

- Rethinking the Weakest Link in State Government Cybersecurityon April 24, 2024 at 2:07 am

Recent cyberattacks in Fulton County, Ga., Contra Costa County, Calif., and the Office of the Colorado State Public Defender have prompted widespread delays and forced state and local entities to shut ...

- Rethinking Leadership: Are You Willing to Be a Servant Leader?on April 21, 2024 at 5:00 pm

Management positions are no longer the stuff of dreams. Is it because we were misled about what they really entail? I explored this in a recent paper in Organizational Dynamics, suggesting that ...

- Rethinking work dynamics: Why consumer browsers are no longer enoughon April 18, 2024 at 5:00 pm

What sets enterprise browsers apart? They are designed from the ground up as a security product with productivity in mind. Learn more today. In the fast-paced realm of modern business, adaptation ...

- Rethinking Groupthinkon April 17, 2024 at 5:00 pm

The concept of "groupthink," first identified by Irving Janis, refers to the phenomenon in which group members quickly align on certain decisions without critically evaluating or suppressing ...

- Larry Fink’s Question Of When Retirement Begins Is A Systems Challengeon April 9, 2024 at 7:12 am

Rethinking retirement and retirement age requires ... Today, technology, particularly automation, is making work less physically demanding, theoretically making it possible for people to work ...

- New state of mind: Rethinking how researchers understand brain activityon April 8, 2024 at 5:00 pm

Understanding the link between brain activity and behavior is among the core interests of neuroscience. Having a better grasp of this relationship will both help scientists understand how the ...

The Latest Google Headlines on:

Rethinking Automation

[google_news title=”” keyword=”Rethinking Automation” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Automation systems

- Automated Test Equipment Market To Cross USD 10.6 Billion By 2031 Driven By Increasing Demand In Consumer Electronicson May 8, 2024 at 11:27 pm

( MENAFN - Evertise Digital) - The Automated Test Equipment Market Size to reach USD 10.6 Billion by 2031, reflecting a Compound Annual Growth Rate (CAGR) of 4.62% over the 2024-2031 period, the ...

- Investigators want Tesla to guarantee fixes to Autopilot system worked amid more crasheson May 8, 2024 at 5:30 pm

AUSTIN, Texas — Federal highway safety investigators want Tesla to tell them how and why it developed the fix in a recall of more than 2 million vehicles equipped with the company's Autopilot ...

- Reliable Robotics Delivers KC-135 Stratotanker Automation Roadmap to U.S. Air Forceon May 8, 2024 at 11:55 am

Reliable Robotics, a leader in safety-enhancing aircraft automation systems, today announced completion of a KC-135 Stratotanker Automation Study for the U.S. Air Force (USAF). The study was ...

- Five Things to Consider Before Adopting Robotics for Warehouse Automationon May 8, 2024 at 10:54 am

Modern retailers have an incredible opportunity to futureproof their warehouse operations today, with the goal of increasing efficiency to meet this surging consumer demand.

- Shubham Automation selects Dassault Systems platform for faster product developmenton May 8, 2024 at 6:00 am

By adopting this portfolio of solutions, Shubham Automation has a significant leap in its development processes, the company said.

- Building Automation: Extreme Comfort with Hidden Threatson May 7, 2024 at 11:50 am

In the fast-paced world of smart homes and buildings, indoor air quality often takes a backseat. The MOX technology offers a seamless solution to make your space smarter and ...

- Water Automation and Instrumentation Market Growth: Anticipated 8.1% CAGR with a Projected Value of USD 48 Billion by 2033on May 7, 2024 at 7:42 am

A comprehensive analysis by Future Market Insights (FMI), a well-respected market research and consulting firm certified by ESCOMAR, anticipates significant growth in the water automation and ...

- Mechanoid Unveils Revolutionary AI and Automation Suite to Boost Small Business Sales and Efficiencyon May 7, 2024 at 7:40 am

Mount Waverley, Victoria - Mechanoid, a leader in business optimization and automation solutions, has announced the launch of its new software aimed at transforming small business marketing and sales ...

- Building Automation Systems Market Analysis: Industry Reaching USD 96,264 million by 2033on May 6, 2024 at 11:54 pm

Outbound Tourism in Germany: Projected to Reach USD 292,799.9 Million by 2034, With a Forecasted Growth Rate of 9.8% Government Initiatives: Many governments are offering incentives and regulations ...

- Hamilton BiOS Automated Storage Systems to Strengthen UK Biobank’s Efforts Towards Improving Human Healthon May 4, 2024 at 6:48 pm

Enhanced and expanded automated sample storage is central to UK Biobank’s new Manchester Science Park facility.United States - May 4, 2024 — ...

The Latest Google Headlines on:

Automation systems

[google_news title=”” keyword=”automation systems” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]