Experts agree that rising Chinese labor costs and improving U.S. technology will gradually cause significant manufacturing activity to return to the United States.

When it does, a new interdisciplinary manufacturing venture called the Advanced Manufacturing Technology (AMTecH) group at the University of Iowa College of Engineering’s Center for Computer Aided Design (CCAD) will likely help lead the charge.

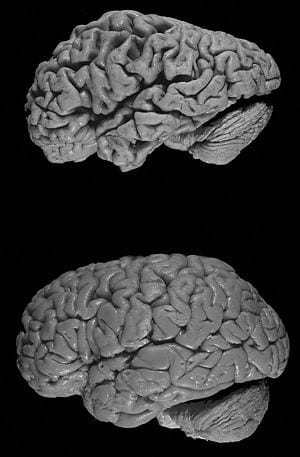

AMTecH was formed to design, create, and test—both virtually and physically—a wide variety of electromechanical and biomedical components, systems and processes. Currently, the group is working on projects ranging from printed circuit boards for automobiles and aircraft to replacement parts for damaged and failing human organs and tissue, says Tim Marler, AMTecH co-director.

“Electromechanical systems are one of two current branches of the AMTecHgroup,” he says. “We want to simulate, analyze and test printed circuit boards and assemblies, because they are used in a wide range of products from missiles to power plants to cell phones.

“The second branch of the group involves biomanufacturing and is led by my colleague and AMTecH co-director Ibrahim Ozbolat, assistant professor of mechanical and industrial engineering,” says Marler. “The long-term goal of this branch is to create functioning human organs some five or 10 years from now. This is not far-fetched.”

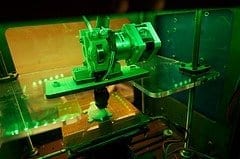

Using its facilities for engineering living tissue systems, the Biomanufacturing Laboratory at CCAD is working to develop and refine various 3D printing processes required for organ and tissue fabrication, Ozbolat says.

“One of the most promising research activities is bioprinting a glucose-sensitive pancreatic organ that can be grown in a lab and transplanted anywhere inside the body to regulate the glucose level of blood,” says Ozbolat. He adds that the 3D printing, as well as virtual electronic manufacturing, being conducted at AMTecH are done nowhere else in Iowa.

In fact, the multi-arm bio printer being used in the lab is unique. Ozbolat and Howard Chen, a UI doctoral student in industrial engineering, designed it and Chen built it. It turns out that managing multiple arms without having them collide with one another is difficult enough that other printers used in other parts of the world avoid the problem by using simpler designs calling for single-arm printing. As Chen continues to refine his and Ozbolat’s design, the UI printer currently gives the UI researchers a distinct advantage.

While bioprinters at other institutions use one arm with multiple heads to print multiple materials one after the other, the UI device with multiple arms can print several materials concurrently. This capability offers a time-saving advantage when attempting to print a human organ because one arm can be used to create blood vessels while the other arm is creating tissue-specific cells in between the blood vessels.

The Latest Bing News on:

Bioink

- College of Engineering Winter 2024 Activity Roundupon April 22, 2024 at 4:59 pm

Faculty and researchers in the College of Engineering made significant contributions to their fields over the past quarter, publishing studies in highly regarded journals and securing funding for ...

- CollPlant Biotechnologies Ltd Ordinary Shares New CLGNon April 22, 2024 at 4:59 pm

We sell different types of products and services to both investment professionals and individual investors. These products and services are usually sold through license agreements or subscriptions ...

- Scientists harness ultrasound for drug delivery and tissue implantationon April 21, 2024 at 5:00 pm

Research presents an advance in drug delivery and tissue implantation assisted by ultrasound, developed by researchers from the Technion Faculty of Biomedical Engineering. The work is published in ...

- Tiny crystals with a big impact on technology innovationon April 21, 2024 at 5:00 pm

The term crystal in this context does not necessarily refer to a traditional crystalline solid like salt or diamond, but rather to any material with a highly ordered, repeating structure at the ...

- A Deep Dive into the Role of 3D Scaffolds as the Building Blocks for Cultivated Meaton April 16, 2024 at 11:00 am

Companies in the space are experimenting with 3D structures or scaffolds to recreate the structure and taste of animal tissue to make complex products such as ...

- 3D Printing Is Helping To Heal Major Skin Wounds And Could Revolutionize Head And Face Reconstructionon April 8, 2024 at 6:49 pm

Their bioink is made of a network of proteins and stem cells and a clotting solution to bind everything together. The proteins and stem cells are extracted from human fat tissue. “We printed ...

- 3D-printed skin closes wounds and contains hair follicle precursorson March 4, 2024 at 4:01 am

Ravnic's team also obtained stem cells, which have the potential to mature into several different cell types if provided the correct environment, from the adipose tissue to make another bioink ...

- TissueFab® bioink Bone Support Gelon November 16, 2023 at 11:19 am

TissueFab ® - Bone support bioink is designed for two primary applications: it can be used for printing bone scaffolds or as a supportive bioink for bone-specific hydrogel or matrix bioinks.

- TissueFab® Sacrificial bioink for tissue engineering applicationson November 14, 2023 at 4:00 am

Furthermore, the viscosity of TissueFab ® - Sacrificial bioink is stable at both room and human body temperatures, which means it can print at both room temperature and physiological temperature.

- From spaceflight to surgery: The biomedical engineering boomon June 8, 2022 at 10:23 pm

The team has also synthesized a bioink from microspheres and hydrogel, which can release growth factors to maintain the survival of nerve cells. The bioink can be used alongside 3D bioprinted ...

The Latest Google Headlines on:

Bioink

[google_news title=”” keyword=”World Wide Web” bioink=”10″ blurb_length=”0″ show_thumb=”left”] [/vc_column_text]The Latest Bing News on:

Engineering living tissue

- Zoogeochemists measure how animals change the chemistry of their environmentson April 26, 2024 at 5:52 pm

Ecologists are blazing trails in a new field they’ve dubbed zoogeochemistry, which explores how animals influence nutrient cycling and carbon entering and exiting their ecosystems. Through everyday ...

- Interstitium: A Network of Living Spaces Supports Anatomical Interconnectednesson April 26, 2024 at 8:29 am

What researchers once regarded as a byproduct of biology may hold the key to understanding health and disease.

- New laser tech using Raman spectroscopy detects illegal elephant ivoryon April 25, 2024 at 11:23 am

these deeply rooted tusks protrude beyond the jaws of the largest living land animals. According to the World Wildlife Fund, tusks are made of dentine, a hard, dense, bony tissue. These tusks have ...

- New experimental evidence unlocks a puzzle in vascular tissue engineeringon April 25, 2024 at 9:25 am

Angiogenesis is a process of forming hierarchical vascular networks in living tissues. Its complexity makes the controlled generation of blood vessels in laboratory conditions a highly challenging ...

- First combined heart pump, pig kidney transplant in same patient successfulon April 25, 2024 at 7:01 am

NYU Langone surgeons pave the way for xenotransplantation with a successful combined heart pump and gene-edited pig kidney transplant.

- 14 recent scientific breakthroughson April 24, 2024 at 8:40 am

T cells are integral in the immune system but can become "dysfunctional inside tumors." "The approval of Amtagvi represents the culmination of scientific and clinical research efforts leading to a ...

- 3D Printed Silk Bio-Ink Shows Potential for Knee Meniscus Repairon April 24, 2024 at 7:00 am

Researchers have developed a silk-based bio-ink to 3D print a meniscus for better knee repair and regeneration.

- What a week in ‘space’ taught me about living on the Moonon April 22, 2024 at 5:00 am

I spent a week battling anxiety, checking CO2 levels and dehydrating food scraps, but future moonwalkers will have it much worse ...

- Study: Far-UVC light eliminates airborne virus in an occupied roomon April 22, 2024 at 3:02 am

Unlike conventional germicidal UVC light — which kills viruses and bacteria but can only typically be used in unoccupied rooms because direct exposure to it can potentially harm skin and eyes — ...

- Mapúa biological engineering program fits global demandon April 19, 2024 at 7:49 pm

If you had a checkup at a hospital, used electricity, eaten a meal, completed a gym workout, or worn a fitness tracker, chances are you used a bioengineered device or service. Biological engineering, ...

The Latest Google Headlines on:

Engineering living tissue

[google_news title=”” keyword=”engineering living tissue” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]