The technology could produce ethanol at a cost savings of roughly 10 percent

Using a plant-derived chemical, UW-Madison researchers have developed a process for creating a concentrated stream of sugars that’s ripe with possibility for biofuels.

“With the sugar platform, you have possibilities,” says Jeremy Luterbacher, a postdoctoral researcher and the paper’s lead author. “You’ve taken fewer forks down the conversion road, which leaves you with more end destinations, such as cellulosic ethanol and drop-in biofuels.”

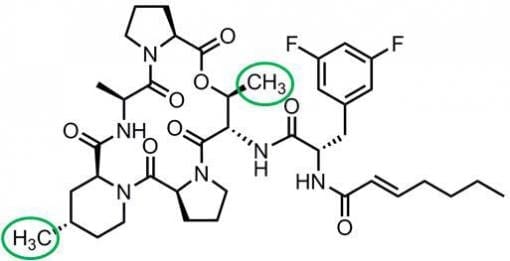

Funded by the National Science Foundation and the U.S. Department of Energy’s Great Lakes Bioenergy Research Center(GLBRC), the research team has published its findings in the Jan. 17, 2014 issue of the journal Science, explaining how they use gamma valerolactone, or GVL, to deconstruct plants and produce sugars that can be chemically or biologically upgraded into biofuels. With support from the Wisconsin Alumni Research Foundation (WARF), the team will begin scaling up the process later this year.

Because GVL is created from the plant material, it’s both renewable and more affordable than conversion methods requiring expensive chemicals or enzymes. The process also converts 85 to 95 percent of the starting material to sugars that can be fed to yeast for fermentation into ethanol, or chemically upgraded furans to create drop-in biofuels.

To demonstrate the economic viability of this advance, Luterbacher needed to concentrate the sugar, remove the GVL for reuse, and show that yeast could successfully generate ethanol from the sugar stream.

“Showing that removing and recycling GVL can be done easily, with a low-energy separation step, is a little more of an achievement,” says Luterbacher. “By feeding the resulting sugar solution to microorganisms, we proved we weren’t producing some weird chemical byproducts that would kill the yeast, and that we were taking out enough GVL to make it nontoxic.”

“What’s neat is that we can use additives to make the solution separate,” says Luterbacher. “It becomes like oil and vinegar.”

Their additive of choice: liquid carbon dioxide.

“It’s green, nontoxic and can be removed by simple depressurization once you want GVL and solutions of sugar to mix again. It’s the perfect additive,” Luterbacher says.

An initial economic assessment of the process has indicated the technology could produce ethanol at a cost savings of roughly 10 percent when compared with current state-of-the-art technologies.

The Latest on: Biofuels

[google_news title=”” keyword=”Biofuels” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Biofuels

- New $60m lab in S’pore to drive R&D in carbon capture, biofuels and hydrogenon April 26, 2024 at 8:20 pm

Transforming Singapore’s energy and chemical sectors will be a priority, says DPM Heng Swee Keat. Read more at straitstimes.com.

- Solketal Industry Projected to Skyrocket to US$ 108.4 Billion by 2032, Fueled by Global Shift Towards Biofuelson April 26, 2024 at 8:29 am

The global solketal industry was worth US$ 76.85 Billion in the year 2022 and is expected to reach US$ 108.4 Billion by the year 2032 at a CAGR of 3.5% between 2022 and 2032. The solketal market is ...

- Long-term strategy for biofuelson April 25, 2024 at 10:33 pm

Daniel Chereau leads IATA's fuel team, focusing on efficiency of fuel supply – including the ramp up of sustainable aviation fuels (SAF). He will be speaking on the second day of the Sustainable ...

- Could Ohio crops power cruise liners and commercial jets? Ohio Congress members offer bills to make it easieron April 25, 2024 at 12:05 pm

A view of the Ocean Explorer, a Bahamas-flagged Norwegian cruise ship. U.S. Rep. Sherrod Brown, a Cleveland Democrat, introduced legislation that would ensure renewable fuel used by ocean-going ...

- Investing in Clean Energy and Domestic Biofuelson April 24, 2024 at 8:12 am

The USDA is funding more than 700 clean energy projects to help lower energy bills, expand access to domestic biofuels, create new jobs, and find new market opportunities for farmers and ranchers. Dep ...

- Biofuels Supply Too Scarce for Shipping Sector, Says Hapag-Lloydon April 23, 2024 at 11:51 pm

There’s currently insufficient production capacity to make biofuels suitable for the shipping sector, making it a challenging option as a sustainable fuel, said Ilyas Muhammad, head of green fuels at ...

- USDA funding clean energy and biofuels in Kansason April 23, 2024 at 4:51 pm

TOPEKA, Kan. (KSNW) — The U.S. Department of Agriculture has announced over $5.3 million to help fund seven clean energy projects in Kansas.

- Growth Energy touts benefits of biofuels, year-round E15 at Des Moines Earth Day eventon April 23, 2024 at 4:51 pm

A biofuels expert says the EPA’s emergency waiver allowing sales of E15 fuel blends this summer provides certainty for retailers. Jake Comer, vice president of market development for Growth Energy, ...

- Carras Secures ABS' First Biofuel Notation for Aquataurus Bulk Carrieron April 23, 2024 at 1:46 am

Greek shipping company Carras (Hellas) has received the ABS Biofuel-1 notation for its Aquataurus ultramax bulk carrier, the ...

- The criticality of biofuels and their impact on India's economy and ecologyon April 22, 2024 at 11:12 pm

India can reduce its dependence on imported fossil fuels by adopting production of biofuels thereby enhancing energy security and mitigating economic risks.

via Bing News