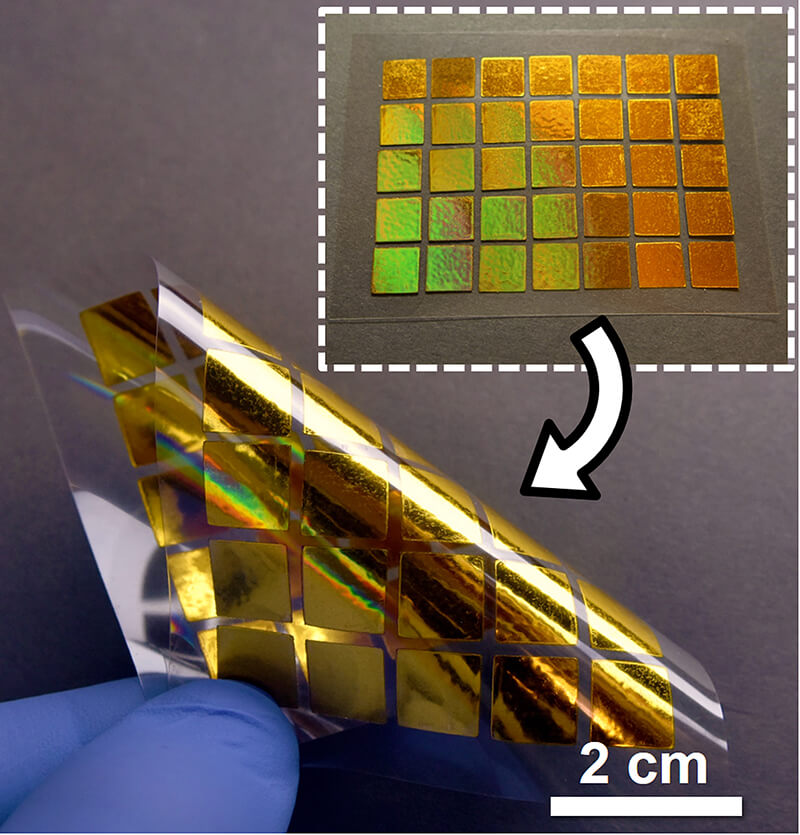

A new manufacturing technique uses a process similar to newspaper printing to form smoother and more flexible metals for making ultrafast electronic devices.

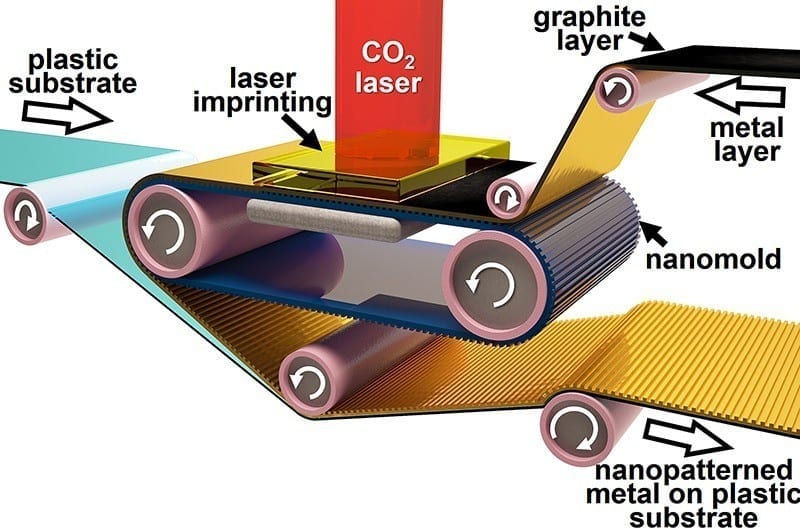

The low-cost process, developed by Purdue University researchers, combines tools already used in industry for manufacturing metals on a large scale, but uses the speed and precision of roll-to-roll newspaper printing to remove a couple of fabrication barriers in making electronics faster than they are today.

Cellphones, laptops, tablets, and many other electronics rely on their internal metallic circuits to process information at high speed. Current metal fabrication techniques tend to make these circuits by getting a thin rain of liquid metal drops to pass through a stencil mask in the shape of a circuit, kind of like spraying graffiti on walls.

“Unfortunately, this fabrication technique generates metallic circuits with rough surfaces, causing our electronic devices to heat up and drain their batteries faster,” said Ramses Martinez, assistant professor of industrial engineering and biomedical engineering.

Future ultrafast devices also will require much smaller metal components, which calls for a higher resolution to make them at these nanoscale sizes.

“Forming metals with increasingly smaller shapes requires molds with higher and higher definition, until you reach the nanoscale size,” Martinez said. “Adding the latest advances in nanotechnology requires us to pattern metals in sizes that are even smaller than the grains they are made of. It’s like making a sand castle smaller than a grain of sand.”

This so-called “formability limit” hampers the ability to manufacture materials with nanoscale resolution at high speed.

Purdue researchers have addressed both of these issues – roughness and low resolution – with a new large-scale fabrication method that enables the forming of smooth metallic circuits at the nanoscale using conventional carbon dioxide lasers, which are already common for industrial cutting and engraving.

“Printing tiny metal components like newspapers makes them much smoother. This allows an electric current to travel better with less risk of overheating,” Martinez said.

The fabrication method, called roll-to-roll laser-induced superplasticity, uses a rolling stamp like the ones used to print newspapers at high speed. The technique can induce, for a brief period of time, “superelastic” behavior to different metals by applying high-energy laser shots, which enables the metal to flow into the nanoscale features of the rolling stamp – circumventing the formability limit.

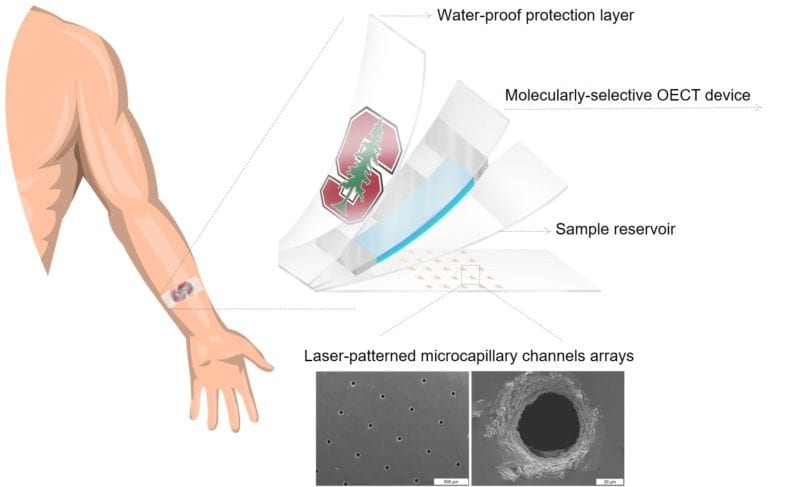

“In the future, the roll-to-roll fabrication of devices using our technique could enable the creation of touch screens covered with nanostructures capable of interacting with light and generating 3D images, as well as the cost-effective fabrication of more sensitive biosensors,” Martinez said.

Learn more: Future electronic components to be printed like newspapers

The Latest on: Roll-to-roll laser-induced superplasticity

[google_news title=”” keyword=”roll-to-roll laser-induced superplasticity” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Roll-to-roll laser-induced superplasticity

- Laser Hackson April 23, 2024 at 7:02 pm

Lasers are pretty much magic — it’s all done with mirrors. Not every laser, of course, but in the 1980s, the most common lasers in commercial applications were probably the helium-neon laser ...

- Toilet Paper Roll Pirate Crafton April 18, 2024 at 5:08 pm

Gather your little mateys for a high seas craft project with this fun toilet paper roll pirate craft for kids. Here's how to make it! All images courtesy of Two Kids and a Coupon Ahoy mateys!

- Laser Induced Breakdown Spectroscopyon April 10, 2024 at 6:29 am

Analysis of Heavy Metal Pollution in Soil Using Transversely Excited Atmospheric CO2 Laser-Induced Plasma by Trapping the Soil in Microstructured Holes on Metal Subtargets. Applied Spectroscopy, Vol.

- Jelly Roll Says He Bailed on Meeting Diddy Because of a Bad Feelingon April 7, 2024 at 5:00 pm

Jelly Roll says he backed out of meeting Diddy at the last minute because he was feeling weird about it. Last Friday (April 5), Jelly Roll and his wife Bunnie stopped by the Cancelled With Tana ...

- Country star Jelly Roll's private jet forced into emergency landingon April 5, 2024 at 1:39 pm

Jelly Roll's private plane had to make an emergency landing while flying to Austin, Texas, for the CMT Music Awards on Thursday night. The country music artist's wife, Bunnie XO, took to TikTok to ...

- Roll-to-roll-fabricated hybrid perovskite solar cells reach record efficiencieson April 4, 2024 at 5:00 pm

On a roll: The roll-to-roll printing technique used to produce hybrid perovskite solar panels with efficiencies of 11% and an area of up to 50 cm2. (Courtesy: D Vak) Large-area solar cells made from ...

- Jelly Roll Talks to This Country Artist as Much as He Does His Wife, Bunnie Xoon March 29, 2024 at 9:26 am

Jelly Roll then revealed just how much he speaks to Gilbert. “I think I’ve talked to Brantley more hours on the phone than anybody but my wife this year. I mean, that’s my buddy, man.

- Who Is Jelly Roll's Wife? All About Bunnie XOon August 4, 2023 at 12:31 pm

Jelly Roll and Bunnie XO have been married since 2016 Emily Weaver is a contributing writer at PEOPLE. She has been working at PEOPLE since 2022. Her work has previously appeared in POPSUGAR ...

- Three Rolling Strategies Every Covered Call Writer Must Knowon June 8, 2022 at 1:51 pm

To use the strategy well, however, you must understand how—and when—to roll your calls. One of the most common strategies, especially for new traders, is the covered call. To use the strategy ...

via Bing News