A cost-effective method uses fungi to convert palm oil waste to green products

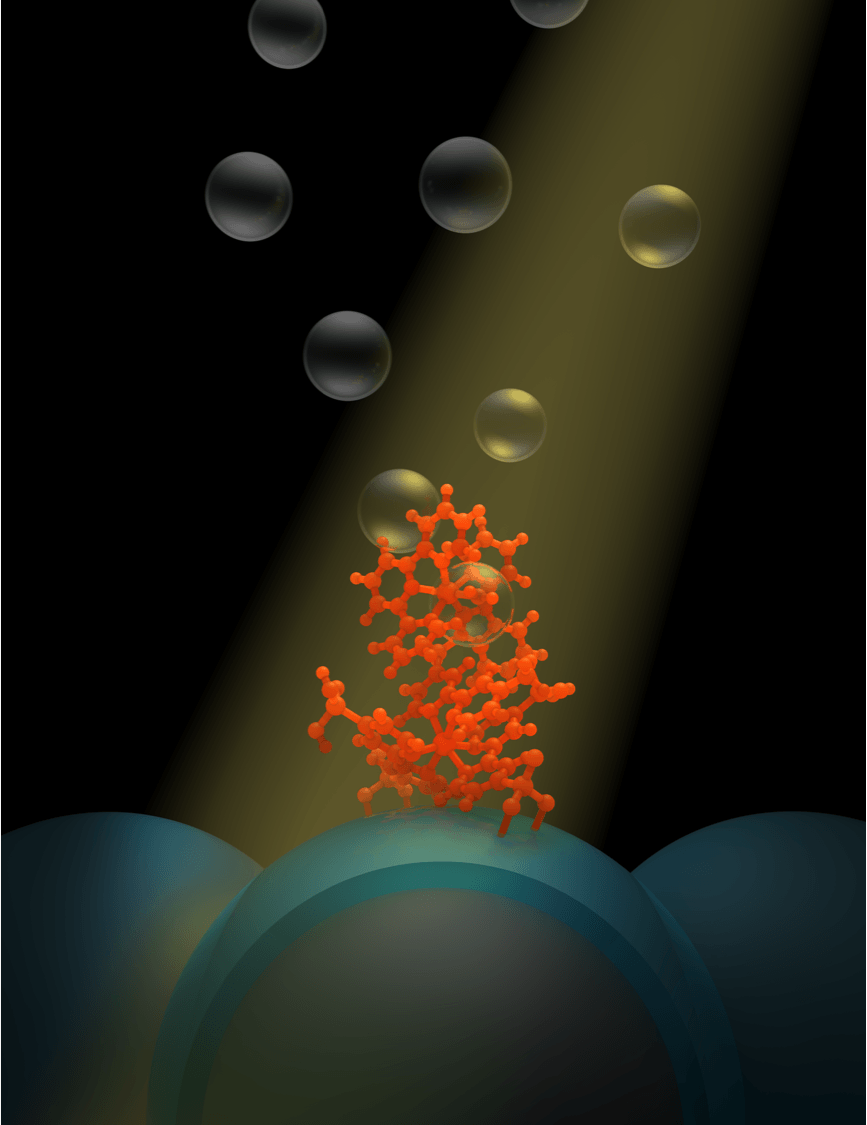

Leftover plant matter from the production of palm oil could provide a generous source for making biofuels and environmentally friendly plastics. Researchers from A*STAR have developed a fungal culture for use in a cheap and efficient method to transform the waste oil palm material into useful products.

The palm oil industry is big business in South Asia, but after harvesting the fruit from the oil palm trees, large amounts of leftover biomass known as empty fruit bunch remain. The industry wants to use these leftover fruit bunches to produce bioethanol and biodegradable plastic, but has stumbled in their efforts to convert the leftovers in a cost-efficient way.

“Our research makes it possible to produce fermentable sugars from this huge amount of waste in a cost-effective way to increase its commercial value,” says one of the lead researchers, Jin Chuan Wu, from the A*STAR Institute of Chemical and Engineering Sciences.

The palm oil waste contains carbohydrate material, known as cellulose and hemicellulose that can be broken down into sugars for use in fuel and plastic production. While the hemicellulose material is easily dissolved by a process known as dilute acid-catalyzed hydrolysis, the cellulose is tougher and remains solid.

The cellulose can be further treated with a mixture of enzymes, but the commercially available mixtures usually do not contain enough of one enzyme — ?-glucosidase — to do the job properly. Higher amounts of ?-glucosidase can be added to the commercial preparations, which then ramps up the cost of converting oil palm biomass into biofuel and bioplastic.

Wu and his team used whole fungal cell cultures to catalyze the breakdown of cellulose instead of the commercial enzyme mixture. They employed a strain of Trichoderma reesei, which produces sufficient amounts of the enzymes necessary to dissolve cellulose.

The research team was pleased with their results, says Wu. The fungal cell cultures converted the cellulose to glucose and achieved a concentration of 8.5 grams per liter after 120 hours — almost 59 per cent of the total potential glucose available in the plant material. In comparison, the commercial enzyme mixture produced 10 per cent less glucose under the same conditions.

In total, the team were able to convert up to 82 per cent of the original plant carbohydrates into fermentable sugars.

Read more: Oil palm offers cheap biofuels and bioplastics

The Latest on: Biofuels and bioplastics

[google_news title=”” keyword=”Biofuels and bioplastics” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Biofuels and bioplastics

- Scientists Are Trying to Mine Seaweedon April 28, 2024 at 4:59 am

Seaweed is versatile; it provides a habitat for marine life, shelters coastlines, and absorbs carbon dioxide. But in the United States, scientists are setting out to see whether seaweed has another ...

- Demand for renewables powers growth at Brazilian ethanol giant Raízenon April 26, 2024 at 2:00 am

With a favourable climate and abundant land to grow the primary ingredients — sugar cane or corn — Brazil has emerged, alongside the US, as one of the world’s largest producers and exporters of ...

- Eni increases share buyback, pledges to cut leverage in 2024on April 24, 2024 at 8:45 am

Italian energy group Eni will cut its leverage in the coming quarters as it turns to disposals and away from major acquisitions, its Chief Financial Officer said on Wednesday, after the group ...

- Global Cellulase Market on Track to Reach US$ 3,263.5 Million by 2033, Boosted by Environmental and Sustainable Trends | FMIon April 23, 2024 at 6:28 am

The cellulase market is expected to grow from US$ 1,685.8 million in 2023 to US$ 3,263.5 million by 2033, with a CAGR of 6.8% from 2023 to 2033. The global cellulase sector expanded at a CAGR of 6.8% ...

- Biorefinery Market Soars To USD 296.31 Billion By 2031 With A CAGR Of 8.61% – Comprehensive Analysis And Growth Insights From 2024-2031on April 21, 2024 at 12:23 am

SNS Insider has projected a CAGR of 8.61%, the biorefinery market size is anticipated to reach over $296.31 billion by the year 2031.

- 11 American Companies On the Cutting Edge of Renewable Techon April 19, 2024 at 10:30 am

Renewable tech is an uphill battle against polluting behemoths, but these companies are working to protect our planet.

- Eni to sell stakes in biofuel, bioplastic units by end of 2024on April 16, 2024 at 8:13 am

Italian energy group Eni aims to sell by year-end minority stakes in its biofuel and bio-plastic units that could fetch around $1.47 B in total to speed up its energy transition.

- Eni (E) Plans Stake Sales in Biofuel, Bioplastic Unitson April 16, 2024 at 5:25 am

Eni (E) aims to drive sustainability by offloading stakes in biofuel and bioplastic units, totaling approximately 1.3 billion euros, thereby accelerating its sustainable energy transition plan.

- Eni aims to sell stakes in biofuel, bioplastic units by year-end - Reuterson April 15, 2024 at 9:16 am

Eni (NYSE:E) will seek to sell minority stakes in its biofuel and bio-plastic units by the end of this year, in deals that could fetch a combined ~€1.3B to speed up its energy transition, Reuters ...

- Exclusive-Eni aims to sell stakes in biofuel, bioplastic units by year-end, sources sayon April 15, 2024 at 8:27 am

MILAN (Reuters) - Italian energy group Eni aims to sell by year-end minority stakes in its biofuel and bio-plastic units that could fetch around 1.3 billion euros in total to speed up its energy ...

via Bing News