Prosthetics with a realistic sense of touch. Bridges that detect and repair their own damage. Vehicles with camouflaging capabilities.

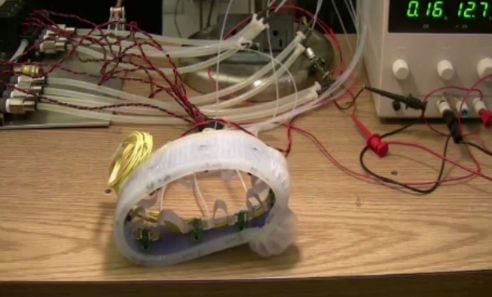

Advances in materials science, distributed algorithms and manufacturing processes are bringing all of these things closer to reality every day, says a review published today in the journal Science by Nikolaus Correll, assistant professor of computer science, and research assistant Michael McEvoy, both of the University of Colorado Boulder.

The “robotic materials” being developed by Correll Lab and others are often inspired by nature, Correll said.

“We looked at organisms like the cuttlefish, which change their appearance depending on their environment, and the banyan tree, which grows above-ground roots to support the increasing weight of the trunk,” Correll said. “We asked what it would take to engineer such systems.”

Robotic materials require tight integration between sensing, computation and actually changing the materials properties of the underlying material. While materials can already be programmed to change some of their properties in response to specific stimuli, robotic materials can sense stimuli and determine how to respond on their own.

Correll and McEvoy use the example of artificial skin equipped with microphones that would analyze the sounds of a texture rubbing the skin and route information back to the central computer only when important events occurred.

“The human sensory system automatically filters out things like the feeling of clothing rubbing on the skin,” Correll said. “An artificial skin with possibly thousands of sensors could do the same thing, and only report to a central ‘brain’ if it touches something new.”

While all of these materials are possible, the authors caution that manufacturing techniques remain a challenge.

“Right now, we’re able to make these things in the lab on a much larger scale, but we can’t scale them down,” Correll said. “The same is true for nano- and microscale manufacturing, which can’t be scaled up to things like a building façade.”

The field also faces an education gap, the authors say. Developing robotic materials requires interdisciplinary knowledge that currently isn’t provided by materials science, computer science or robotics curricula alone.

Read more: Robotic materials: Changing with the world around them

The Latest on: Robotic materials

[google_news title=”” keyword=”Robotic materials” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Robotic materials

- Robot-Explorers, Futuristic SpaceX Starships Set To Transform The Moonon April 27, 2024 at 5:09 pm

Simultaneous revolutions in creating AI-enhanced space robots and in spaceflight with SpaceX's super-advanced Titan-size Starship capsules, are set to transform the Moon.

- Dyson’s new robot vacuum is $1,200 — here are some of our more affordable favoriteson April 27, 2024 at 7:00 am

We love Dyson's other vacuums. And this robot vacuum is packed with features. But does it justify that price tag?

- AI robot graduation speaker is not A-OK for some students at D'Youvilleon April 26, 2024 at 11:46 am

D'Youville has invited Sophia, a humanoid automaton produced by Hong Kong-based Hanson Robotics, to address its graduates at the May 11 ceremony at LECOM Harborcenter. And that is a problem for scores ...

- Automated machine learning robot unlocks new potential for genetics researchon April 26, 2024 at 9:10 am

University of Minnesota Twin Cities researchers have constructed a robot that uses machine learning to fully automate a complicated microinjection process used in genetic research.

- OSARO Snags SVP Brent Barcey from Plus One Roboticson April 26, 2024 at 8:30 am

Barcey joins OSARO from Plus One Robotics, where he served as vice president of sales and business development. In this position, he played a key role in driving revenue and estab ...

- RICE develops new underwater robot with a buoyancy control system using fuel cellson April 26, 2024 at 4:31 am

Rice University students have made a breakthrough in underwater robotics by creating a remotely operated vehicle (ROV) that utilizes water-splitting fuel cells for buoyancy control. This innovative ...

- Robotic nerve 'cuffs' could help treat a range of neurological conditionson April 26, 2024 at 2:00 am

Researchers have developed tiny, flexible devices that can wrap around individual nerve fibers without damaging them.

- Sanctuary’s new humanoid robot learns faster and costs lesson April 25, 2024 at 12:42 pm

Sanctuary AI often isn’t mentioned in the same breath as humanoid robotics firms like Boston Dynamics, Agility, Figure and 1X, but the Canadian company ...

- The Eufy Omni S1 Pro Robot Vacuum Doesn't Live Up to the Hypeon April 24, 2024 at 6:31 pm

In this review of Eufy's Omni S1 Pro robot vacuum, I determined that it isn’t a good buy. There’s a disconnect between the robot Eufy thinks they built and the one I tested.

- Meet Thermonator, a robotic dog equipped with a flamethroweron April 24, 2024 at 5:56 pm

An Ohio company is now selling something we never knew we needed (and maybe it’s best that we didn't) — a flamethrowing robot dog.

via Bing News