Researchers from North Carolina State University have developed a new way to shape ceramics using a modest electric field, making the process significantly more energy efficient. The process should result in significant cost savings for ceramics manufacturing over traditional manufacturing methods.

Ceramics make up significant components of an array of products, including insulators, spark plugs, fuel cells, body armor, gas turbines, nuclear rods, high temperature ball bearings, high temperature structural materials and heat shields.

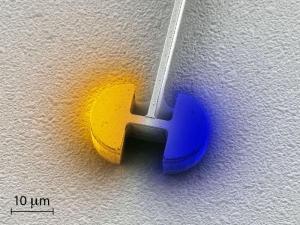

At issue are crystalline defects found in crystalline materials, such as ceramics. “One of these defects is called a grain boundary, which is where crystals with atoms aligned in different directions meet in the material,” says Dr. Hans Conrad, emeritus professor of materials science and engineering at NC State and co-author of the study. These boundaries have electrical charges.

“We found that if we apply an electric field to a material, it interacts with the charges at the grain boundaries and makes it easier for the crystals to slide against each other along these boundaries. This makes it much easier to deform the material.” In other words, the material becomes superplastic — so a ceramic can be shaped into a desirable form using a small amount of force.