Biomedical engineers cut post-processing steps to make electrospun nanofibers for wound healing and improve 3D-matrices for biological tissues. They speed up prototyping using identical materials.

Electrospinning uses electric fields to manipulate nanoscale and microscale fibers. The technique is well-developed but time-intensive and costly. A team from Michigan Technological University came up with a new way to create customizable nanofibers for growing cell cultures that cuts out time spent removing toxic solvents and chemicals. Their work is published in Elsevier’s Materialia (DOI: 10.1016/j.mtla.2019.100296).

Smitha Rao, assistant professor of biomedical engineering at Michigan Tech, led the research. She said the approach is innovative, “we’re coming at this completely sideways,” and the team focused on streamlining electrospun nanofiber production. Nanofibers are used as scaffolds, made up of strands and pockets, that can grow cells.

“We want an assembled, highly aligned scaffold that has ideal structures and patterns on it that cells will like,” Rao said. “Take a cell, put it on porous materials versus elastic materials versus hard materials, and it turns out the cell does different things. Usually you use varied materials to get these diverse characteristics. Cells respond differently when you put them on different surfaces, so can we make scaffolds that provide these different conditions while keeping the materials the same?”

Nanofiber Strands and Pockets

In a nutshell, yes. And making customizable scaffolds is surprisingly simple, especially when compared to the laborious casting and additive processes typically used to produce scaffolds suitable for electrospinning. Plus, Rao’s team discovered a pleasant side effect.

“We take the polymers, then we put them into solutions, and we came up with this magical formula that works — and then we had to go electrospin it,” Rao explained, adding that the team noticed something odd during the process.

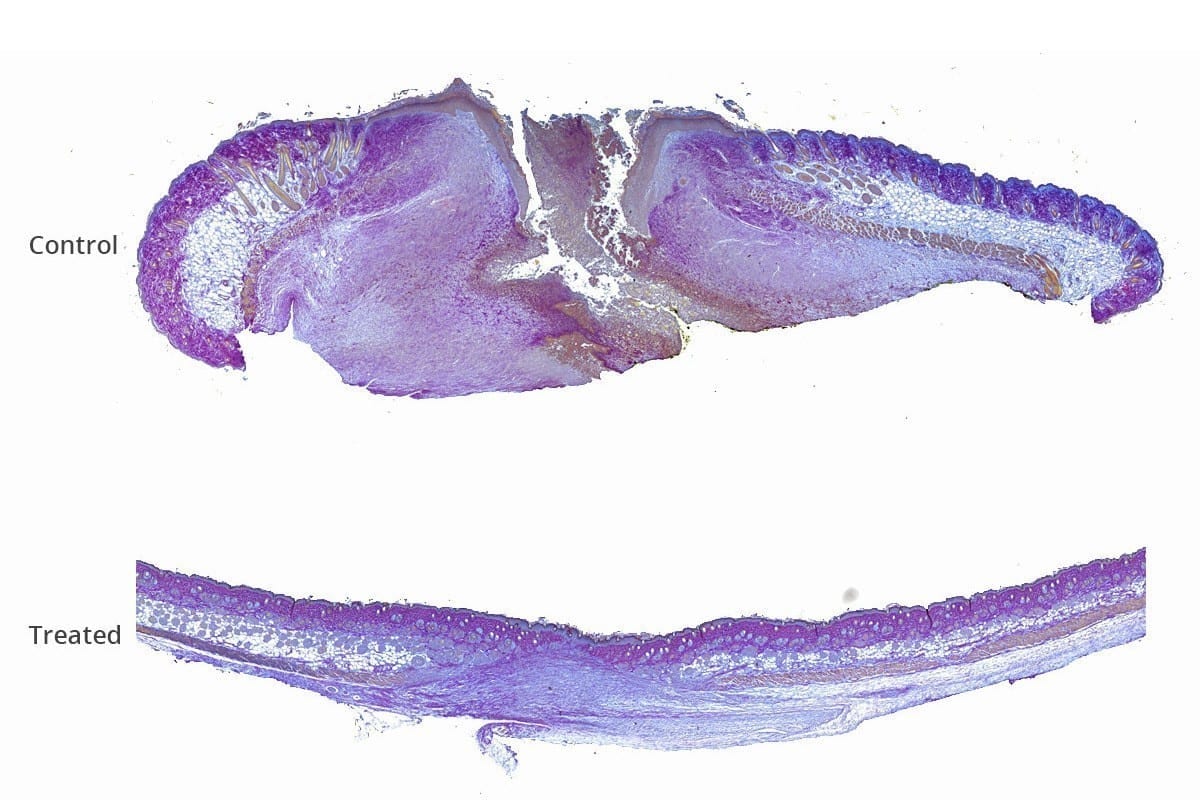

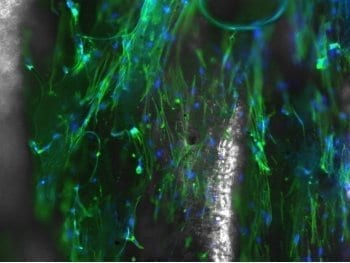

“We saw that the cells aligned without us applying anything externally. Typically, to make them align you have to put them in an electric field, or put them in a chamber and agitate the scaffold to force them to align in a particular direction by applying external stresses,” she said. “We’re basically taking pieces of this scaffold, throwing it in a culture plate and dropping cells on it.”

When spun in an electric field — imagine a cotton candy machine — the self-aligning cells follow the strand-and-pocket pattern of the underlying nanofibers. Rao’s team, including lead author and PhD student Samerender Nagam Hanumantharao and master’s student Carolynn Que, found that varying electric field strengths result in different pocket sizes. At 18 kilovolts, the magic happens and the fibers align just so. At 19 kilovolts, small pockets form, ideal for cardiac myoblasts. At 20 kilovolts, honeycombs of pockets expand in the fibers. Bone cells prefer the pockets formed at 21 kilovolts; dermal cells aren’t picky, but especially like the spacious rooms that grow at 22 kilovolts.

Multi-strand Nanofibers

Rao’s team tested a variety of polymer mixes and found that some of the most common materials remain tried-and-true. Their magical two-polymer blend let them manipulate the nanofiber pocket size; a three-polymer blend made tweaking the mechanical properties possible. The polymers include polycaprolactone (PCL), biodegradable and easy to shape, and conductive polyaniline (PANI), which together made a two-polymer blend, which could be combined with polyvinylidene difluoride (PVDF).

“Because polyaniline is conducting in nature, people can throw it into the fiber matrix to get conductive scaffolds for cells such as neurons,” Rao said. “However, no one has used these materials to manipulate the process conditions.”

Being able to use the same materials to create different nanofiber characteristics means eliminating chemical and physical variables that can mess with experimental results. Rao hopes that as more researchers use her team’s blends and process, it will speed up research to better understand neural mechanisms, speed up wound healing technology, test cell lines and boost rapid prototyping in biomedical engineering.

“We’re trying to simplify the process to answer a highly complex question: how do cells proliferate and grow?” Rao said. “This is our basic building block; this is the two-by-two Lego. And you can build whatever you want from there.”

Learn more: Engineers Craft the Basic Building Block for Electrospun Nanofibers

The Latest on: Electrospun nanofibers

[google_news title=”” keyword=”electrospun nanofibers” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Electrospun nanofibers

- Nanofibers Industry Poised for Exponential Growth: 26% CAGR Anticipated from 2023 to 2028on May 2, 2024 at 2:13 am

BOSTON, May 2, 2024 /PRNewswire/ -- According to the latest BCC Research study, the demand for Global Markets and Technologies for Nanofibers is growing from $2.9 billion in 2023 to $9.4 billion by ...

- Nanofibers rid water of hazardous dyeson April 23, 2024 at 5:00 pm

Nanofibers rid water of hazardous dyes Dyes are a major environmental problem. Efficient filters have now been developed -- based on cellulose waste Date: April 24, 2024 Source: Vienna University ...

- Ph.D. Dissertation Proposal Defense in Plastics Engineering: Taiyo Yamaguchi 4/26on April 22, 2024 at 4:59 pm

This research examines the capabilities of UiO-66-NH2 metal organic frameworks by mechanically encapsulating them within a non woven fiber mat through a process of co-electrospinning/spraying. MOF ...

- The Nanofibers in '3 Body Problem' Are Real, and Yes, They Can Do Thaton March 26, 2024 at 1:33 pm

One of the biggest concepts introduced in 3 Body Problem is the idea of nanotechnology, and, specifically, nanofibers. The Three-Body Problem book's protagonist has this as one of his many skills ...

- Understanding Nanofibers: Their Production, Properties, and Applicationson March 9, 2024 at 4:39 am

Definition: Nanofibers are fibers with diameters in the nanometer range, typically less than 100 nm. They are known for their high surface area to volume ratio, flexibility in surface functionalities, ...

- Understanding Electrospinning for Nanofiber Productionon February 23, 2024 at 6:35 am

As research continues, we can anticipate further improvements in electrospinning techniques, broadening their applicability and efficiency in producing high-quality nanofibers for a growing range of ...

- Experts infuse cotton fabric with nanodiamonds for optimal body coolingon February 16, 2024 at 5:30 pm

The researchers coated cotton with an adhesive, electrospun it with a polymer solution containing nanodiamonds, polyurethane, and solvent, and then cured the fabric to bond the nanofibers. The ...

- Fundamentals and Applications of Micro- and Nanofiberson November 26, 2023 at 4:08 pm

Tokarev, Alexander Trotsenko, Oleksandr Asheghali, Darya Griffiths, Ian M. Stone, Howard A. and Minko, Sergiy 2015. Reactive Magnetospinning of Nano‐ and ...

- Scott Sell, Ph.D.on October 27, 2023 at 9:27 am

Sell conducts research in the areas of tissue engineering and regenerative medicine, particularly focusing on the potential for electrospinning to create extracellular matrix analogue scaffolds for ...

- Koyal Garg, Ph.D.on October 15, 2023 at 5:08 pm

McClure MJ, Garg K, RodrigueIA, McCool JM, Bowlin GL (2011), ECM Analogues Obtained by Electrospun Nanofibers, In Electrospinning for Advanced Biomedical Applications and Therapies, iSmithers Rapra ...

via Bing News