In tests, this increased the service life of the coating by 300%

Researchers at University West in Sweden have started using nanoparticles in the heat-insulating surface layer that protects aircraft engines from heat. In tests, this increased the service life of the coating by 300%. This is something that interests the aircraft industry to a very great degree, and the hope is that motors with the new layers will be in production within two years.

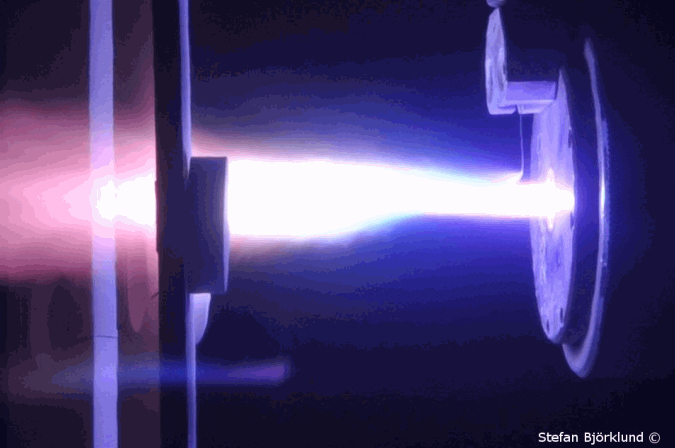

To increase the service life of aircraft engines, a heat-insulating surface layer is sprayed on top of the metal components. Thanks to this extra layer, the engine is shielded from heat. The temperature can also be raised, which leads to increased efficiency, reduced emissions, and decreased fuel consumption.

The goal of the University West research group is to be able to control the structure of the surface layer in order to increase its service life and insulating capability. They have used different materials in their work.

– “The base is a ceramic powder, but we have also tested adding plastic to generate pores that make the material more elastic,” says Nicholas Curry, who has just presented his doctoral thesis on the subject.

Great stress on the material

The ceramic layer is subjected to great stress when the enormous changes in temperature make the material alternately expand and contract. Making the layer elastic is therefore important. Over the last few years, the researchers have focused on further refining the microstructure, all so that the layer will be of interest for the industry to use.

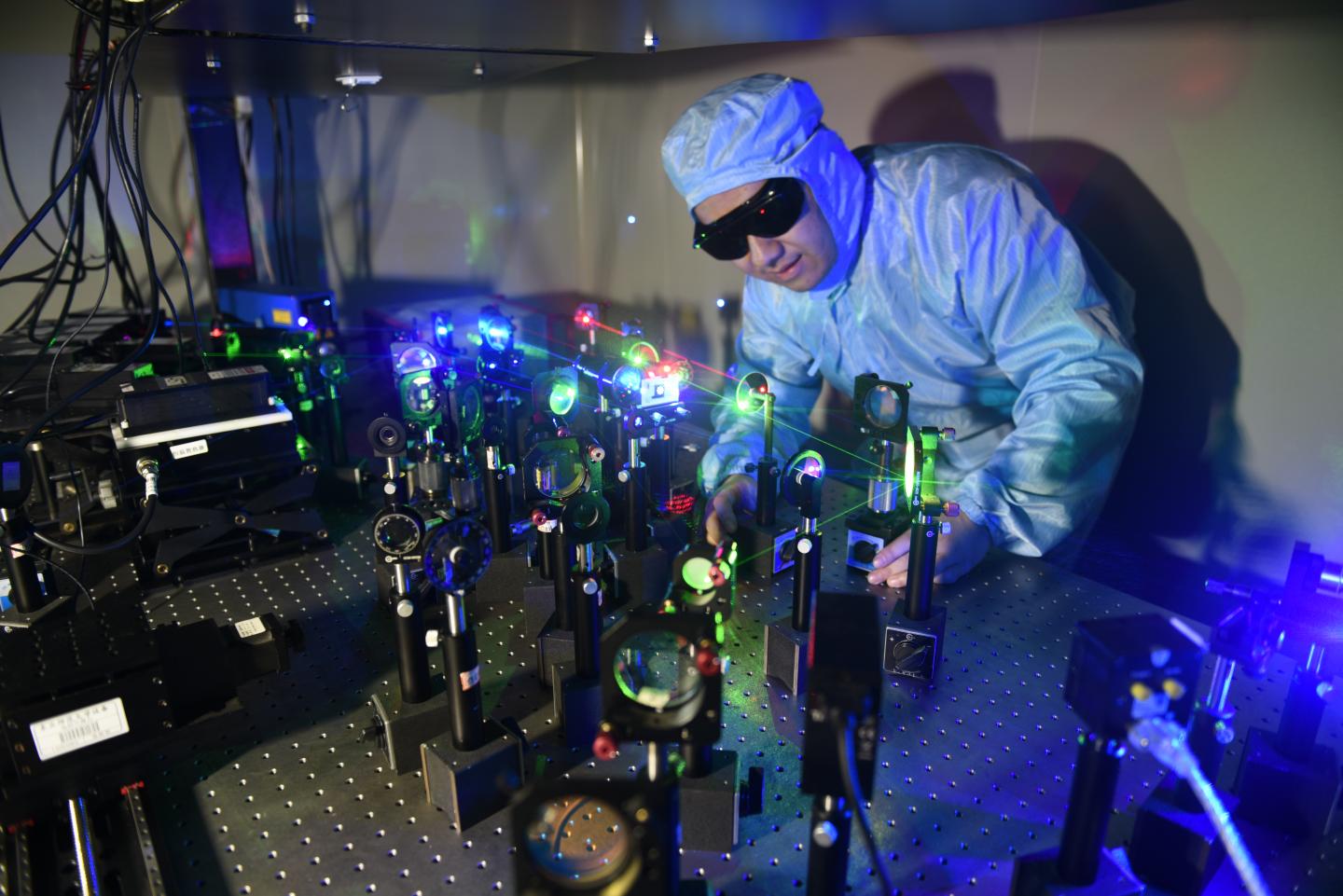

– “We have tested the use of a layer that is formed from nanoparticles. The particles are so fine that we aren’t able to spray the powder directly onto a surface. Instead, we first mix the powder with a liquid that is then sprayed. This is called suspension plasma spray application.

Shock tests simulate temperature changes

Dr Curry and his colleagues have since tested the new layer thousands of times in what are known as “thermal shock tests” to simulate the temperature changes in an aircraft engine. It has turned out that the new coating layer lasts at least three times as long as a conventional layer while it has low heat conduction abilities.

– “An aircraft motor that lasts longer does not need to undergo expensive, time-consuming “service” as often; this saves the aircraft industry money. The new technology is also significantly cheaper than the conventional technology, which means that more businesses will be able to purchase the equipment.

The Latest on: Nanoparticle based coating

[google_news title=”” keyword=”Nanoparticle based coating” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Nanoparticle based coating

- Activity in a room stirs up nanoparticles left over from consumer sprayson May 1, 2024 at 5:10 am

Common household products containing nanoparticles -- grains of engineered material so miniscule they are invisible to the eye -- could be contributing to a new form of indoor air pollution, according ...

- Aurobindo Pharma gets grant for stable pharmaceutical composition of amorphous canagliflozinon April 30, 2024 at 5:41 am

Discover Aurobindo Pharma's innovative pharmaceutical composition with amorphous canagliflozin, ensuring stability and bioavailability. Patent US11857559B2 reveals a binder-free formula lasting 6 ...

- Lipid-based Nanoparticles in the Systemic Delivery of siRNAon April 27, 2024 at 5:00 pm

Lipoprotein-based nanoparticles with excellent biocompatibility, favorable pharmacokinetics, nonimmunogenicity, suitably small size (

- Purdue researchers create biocompatible nanoparticles to enhance systemic delivery of cancer immunotherapyon March 26, 2024 at 5:00 pm

“We employed poly (lactic-co-glycolic acid), or PLGA, nanoparticles based on the strong track record of the polymer in FDA-approved products and its routine use in the systemic delivery of poorly ...

- Nanoparticle Based Delivery of Gene Editing Enzymeson March 26, 2024 at 12:00 am

Cas9 based therapeutics have the potential to revolutionize the ... CRISPR-Gold is composed of gold nanoparticles assembled with the Cas9/gRNA ribonucleoprotein (RNP) complex, donor DNA, and an ...

- Introducing multi-component liquid-infused surfaces for adaptive and functional coatingson March 6, 2024 at 12:52 pm

Surface coatings have long been essential in various ... The study categorizes these surfaces based on the size of their secondary components, ranging from molecular to microscale, and presents ...

- Aluminum nanoparticles make tunable green catalystson March 5, 2024 at 1:49 pm

The properties of the nanoparticles' oxide coating determine how they interact ... Tailoring the aluminum nanocrystal surface oxide for all-aluminum-based antenna-reactor plasmonic photocatalysts ...

- 2nd Next-Generation Lipid-Based Nanoparticle Delivery Summiton March 29, 2023 at 5:00 pm

2023 is set to be a landmark year for lipid-based delivery technology development and the 2nd Next-Generation Lipid-Based Nanoparticle Delivery Summit returns to unite 140+ biopharma thought ...

- The emerging nanomedicine landscapeon September 13, 2020 at 6:20 am

Examples include Biophan's (Henrietta, NY, USA) magnetic nanoparticle–based coating that makes medical implants safe for use with MRI imaging and nanomaterials used for retina implants to ...

- Nanoparticle production – How nanoparticles are madeon August 14, 2020 at 8:17 pm

Micro-emulsion processes are often used to produce nanoparticles for pharmaceutical and cosmetics applications. An additional process that is based on self-organized growth with templates and coatings ...

via Bing News