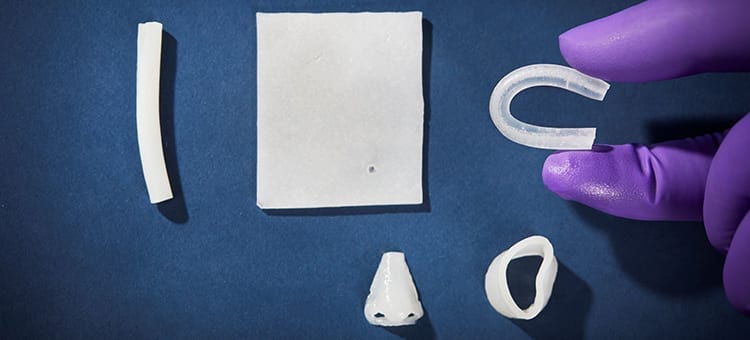

Image: Rajiv Malhotra/Rutgers University-New Brunswick

Scalable and cost-effective manufacturing of thin film devices

Engineers at Rutgers University–New Brunswick and Oregon State University are developing a new method of processing nanomaterials that could lead to faster and cheaper manufacturing of flexible, thin film devices – from touch screens to window coatings, according to a new study.

The “intense pulsed light sintering” method uses high-energy light over an area nearly 7,000 times larger than a laser to fuse nanomaterials in seconds. Nanomaterials are materials characterized by their tiny size, measured in nanometers. A nanometer is one millionth of a millimeter, or about 100,000 times smaller than the diameter of a human hair.

The existing method of pulsed light fusion uses temperatures of around 250 degrees Celsius (482 degrees Fahrenheit) to fuse silver nanospheres into structures that conduct electricity. But the new study, published in RSC Advances and led by Rutgers School of Engineering doctoral student Michael Dexter, showed that fusion at 150 degrees Celsius (302 degrees Fahrenheit) works well while retaining the conductivity of the fused silver nanomaterials.

The engineers’ achievement started with silver nanomaterials of different shapes: long, thin rods called nanowires in addition to nanospheres. The sharp reduction in temperature needed for fusion makes it possible to use low-cost, temperature-sensitive plastic substrates like polyethylene terephthalate (PET) and polycarbonate in flexible devices, without damaging them.

“Pulsed light sintering of nanomaterials enables really fast manufacturing of flexible devices for economies of scale,” said Rajiv Malhotra, the study’s senior author and assistant professor in the Department of Mechanical and Aerospace Engineering at Rutgers–New Brunswick. “Our innovation extends this capability by allowing cheaper temperature-sensitive substrates to be used.”

Fused silver nanomaterials are used to conduct electricity in devices such as radio-frequency identification (RFID) tags, display devices and solar cells. Flexible forms of these products rely on fusion of conductive nanomaterials on flexible substrates, or platforms, such as plastics and other polymers.

“The next step is to see whether other nanomaterial shapes, including flat flakes and triangles, will drive fusion temperatures even lower,” Malhotra said.

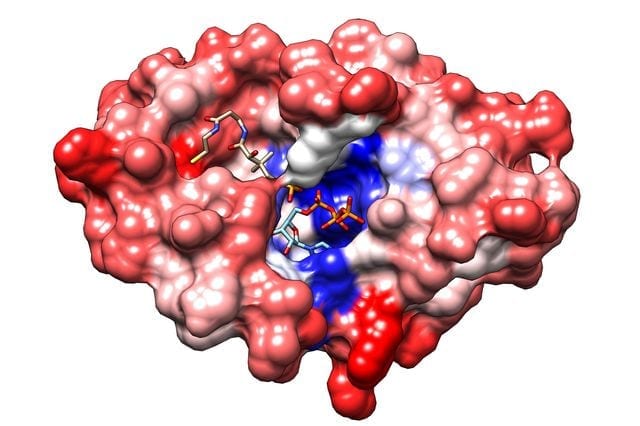

In another study, published in Scientific Reports, the Rutgers and Oregon State engineers demonstrated pulsed light sintering of copper sulfide nanoparticles, a semiconductor, to make films less than 100 nanometers thick.

“We were able to perform this fusion in two to seven seconds compared with the minutes to hours it normally takes now,” said Malhotra, the study’s senior author. “We also showed how to use the pulsed light fusion process to control the electrical and optical properties of the film.”

Learn more: Rutgers-Led Innovation Could Spur Faster, Cheaper Nano-Based Manufacturing

The Latest on: Nano-based manufacturing

[google_news title=”” keyword=”nano-based manufacturing” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Nano-based manufacturing

- Nano Positioning System Market To Reach USD 254.8 Billion By 2032 | DataHorizzon Researchon May 8, 2024 at 10:10 pm

Based on the market segmentation by end-user ... making them ideal for applications requiring nanometer-level accuracy. Advancements in nanotechnology and precision manufacturing drives industry ...

- China’s Focuslight to Buy Micro-Nano Optics Assets From Austria's Ams-Osramon May 8, 2024 at 3:52 am

Focuslight Technologies, a Chinese maker of laser equipment, will pay EUR50 million (USD53.7 million) in cash to acquire the micro-nano optical component assets of Austrian electronics firm Ams-Osram.

- NANO Nuclear Energy Inc.: NANO Nuclear Energy Announces Pricing of Initial Public Offeringon May 8, 2024 at 3:38 am

NANO Nuclear Energy Inc. (NASDAQ: NNE) ("NANO Nuclear") today announced the pricing of its initial public offering of 2,562,500 shares of its common stock ...

- Nanotechnology Market on a Growth Trajectory: Forecasted to Reach USD 33.63 Billion by 2030on May 8, 2024 at 12:14 am

Allied Market Research, titled, “Nanotechnology Market By Type, and Application: Global Opportunity Analysis and Industry Forecast, 2021–2030,” the global nanotechnology market size was valued at ...

- Dotz Nano Ltd DTZZFon May 7, 2024 at 7:25 am

Morningstar Quantitative Ratings for Stocks are generated using an algorithm that compares companies that are not under analyst coverage to peer companies that do receive analyst-driven ratings ...

- Vietnam Nanotechnology in Space Market Share, Growth Statistics, Size, Key Players, and Forecast to 2024 to 2032on May 2, 2024 at 12:00 am

According to the latest report by Report Ocean, titled this “Vietnam Nanotechnology in Space ... We can adjust the report based on the location where you intend to establish your business.

- Vietnam Aerospace Nanotechnology Market Outlook, Share, Top Players, Revenue, Size and Forecast to 2024 to 2032on May 1, 2024 at 11:30 pm

This country research report on Vietnam Aerospace Nanotechnology Market offers ... We can adjust the report based on the location where you intend to establish your business. Manufacturing capacity: ...

- Patitz Awarded NSF Grant for Research on DNA-Based Nanostructure Researchon May 1, 2024 at 10:15 pm

Matthew Patitz, associate professor, plans to construct nanoscale structures using DNA sequences designed to fold into elongated slats that then form complex geometries.

- Assembled with careon April 29, 2024 at 8:59 pm

If you’re trying to visualize what powers manufacturing growth around Roanoke these days, picture 3D-printed helicopter blades and robotics, not old-style grommets. Also known as additive ...

via Bing News