Synopsis:

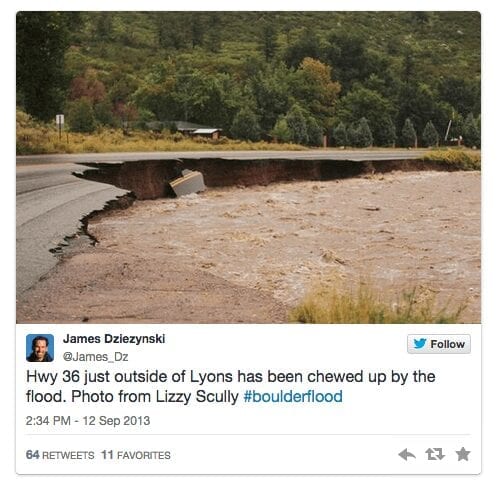

“Mood ring materials” could play an important role in minimizing and mitigating damage to the nation’s failing infrastructure.

That is where “Mood ring materials’ comes in. Sprinkle a pixie dust of nanoparticles into a batch of clear polymer resin and you get”a smart material that changes color when it is damaged or about to fail, what I call a ‘mood ring material,'” explained Cole Brubaker, a doctoral student in civil engineering who is part of an interdisciplinary research team at Vanderbilt University’s Laboratory for Systems Integrity and Reliability developing the new sensing system.

The LASIR researchers are taking a different tack by incorporating fluorescent nanoparticles into the material itself that react to stress by changing their optical properties in order to create a new kind of detection system that can monitor these structures in an efficient and cost-effective fashion.

“So we need to somehow change the materials we are using so they illuminate these tiny cracks.” The team’s initial studies, published last April in the Proceedings of the SPIE Conference on Sensors and Smart Structures Technologies for Civil, Mechanical and Aerospace Systems, have determined that adding a tiny concentration of special nanoparticles to an optically clear polymer matrix produces a distinctive light signature that changes as the material is subjected to a broad range of compressive and tensile loads.

The Vanderbilt group isn’t the only research team using nanoparticles to create smart materials, but they have a special advantage.

They are using a particular type of nanoparticle called a white light quantum dot.

These quantum dots are unique because they emit white light where other quantum dots only emit light at specific wavelengths.

These special quantum dots were accidentally discovered in 2005 in the laboratory of Sandra Rosenthal, Jack and Pamela Egan Professor of Chemistry at Vanderbilt.

“We were trying to make the smallest cadmium selenide quantum dots possible and, when we did, we were astonished to discover that they emit in a broad spectrum,” she recalled.

“White light quantum dots have very unique optical properties compared with other nanoparticles,” said Talitha Frecker, a chemistry graduate student who is participating in the study.

When he learned about Rosenthal’s discovery, he realized that her quantum dots were tailor made for creating smart materials: “When we put these nanoparticles into a material, they observe and react to what is going on around them.” Now Adam’s expectation has been confirmed by the series of preliminary tests that Brubaker and his colleagues have conducted.

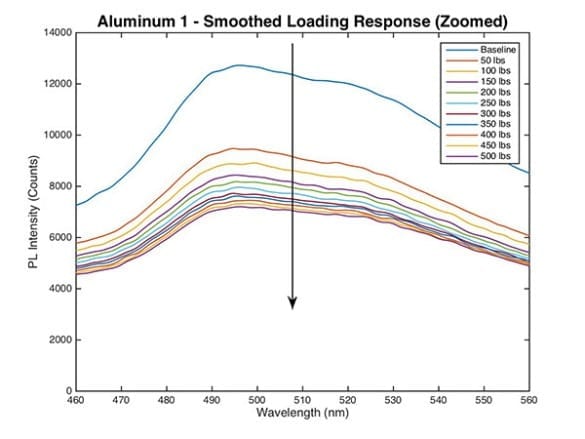

They have coated fiberglass and aluminum strips with a polymer coating containing white light quantum dots and subjected them to varying degrees of external load. They have determined that the intensity of the emission spectrum produced by the quantum dots decreases as the load increases.

The drop-off is largest with the initial loading and gradually decreases at higher levels of load. “The mechanism is still a bit unclear, but we have demonstrated that entrapping these quantum dots in ultra-thin polymer films on metal surfaces can provide advance warning when the underlying metal is about to sustain physical or chemical damage,” said Professor of Chemical and Biomolecular Engineering Kane Jennings, who is participating in the project along with doctoral student Ian Njoroge.

The researchers theorize that the quantum dots emit light in a broad spectrum because more than 80 percent of the atoms lie on the surface.

“The end result is that the strength of the quantum dot emissions gives us a permanent record of the level of stress that a material has experienced,” said Brubaker.

In this fashion, the researchers have verified that the material can act as a new kind of strain gauge that permanently records the cumulative amount of stress that the material to which it is applied experiences.

In their initial experiments, the engineers have kept the loads relatively modest, under 1,250 pounds, well within the elastic limits that the materials can withstand without permanent damage.

This has provided them a baseline that they can use to compare to the results they get as they move to higher loads that cause the materials to begin failing.

As a result, the material must be shielded from external light.

“There is a lot we have to learn before we can create a smart material that is ready for real world applications, but all the signs are positive,” said Adams.

Learn more: Mood ring materials – a new way to detect damage in failing infrastructure

[osd_subscribe categories=’infrastructure-damage’ placeholder=’Email Address’ button_text=’Subscribe Now for any new posts on the topic “INFRASTRUCTURE DAMAGE”‘]

Receive an email update when we add a new INFRASTRUCTURE DAMAGE article.

The Latest on: Infrastructure damage

[google_news title=”” keyword=”infrastructure damage” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Infrastructure damage

- Russian drones set a hotel ablaze in a Ukrainian Black Sea cityon April 28, 2024 at 2:24 am

Officials in Ukraine say Russian drones struck the Black Sea city of Mykolaiv, setting a hotel ablaze and damaging energy infrastructure while ammunition shortages continue to hobble Kyiv’s troops in

- Climate change damage could cost $38 trillion per year by 2050, study findson April 17, 2024 at 8:11 am

BERLIN, April 17 (Reuters) - Damage to farming, infrastructure, productivity, and health from climate change will cost an estimated $38 trillion per year by 2050, German government-backed research finds, a figure almost certain to rise as human activity ...

via Bing News