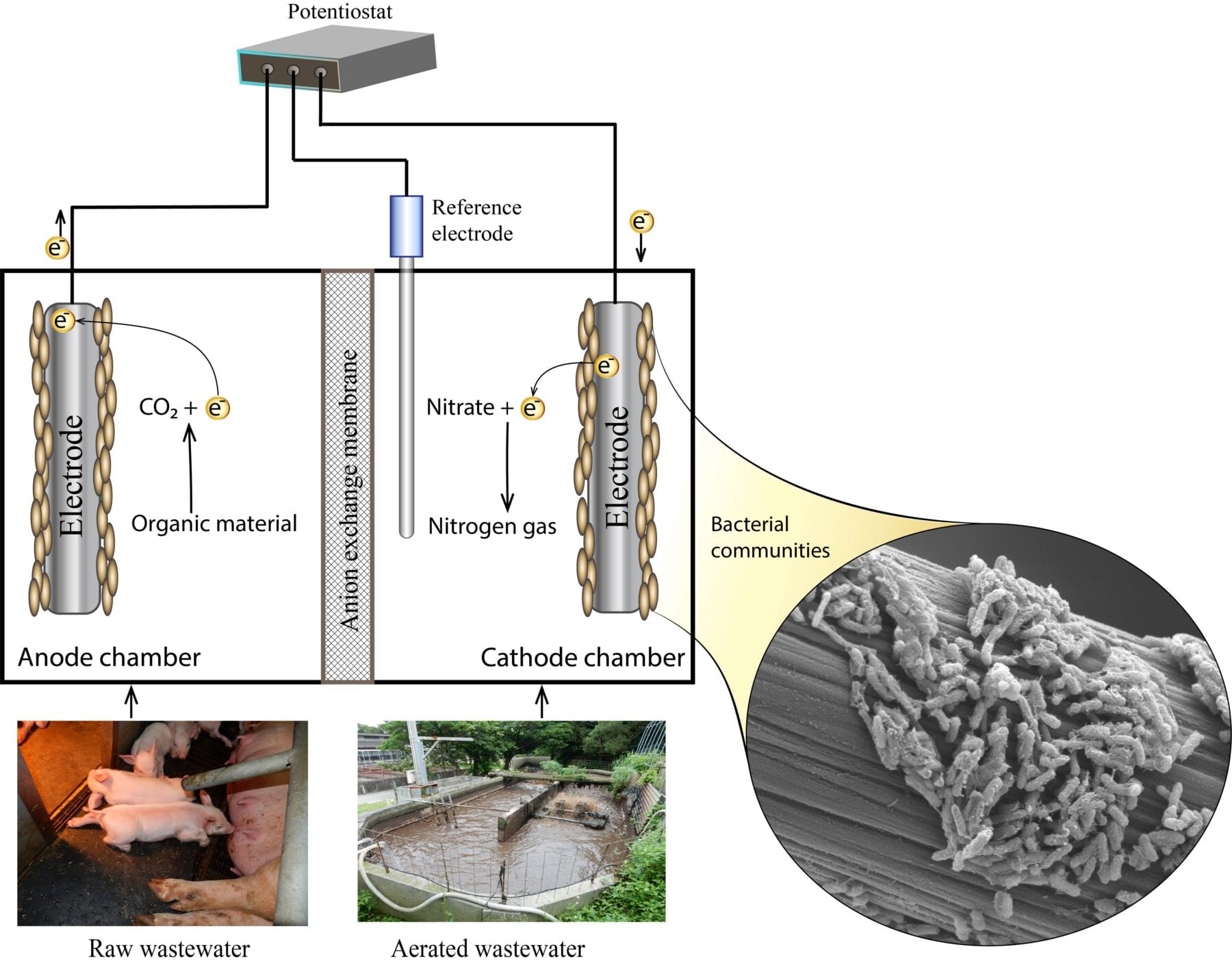

To treat both kinds of water, the researchers devised an ingenious solution; they used microbes to not only drive the treatment process, but also to recover some valuable nutrients out of the wastewater at the same time. The system was created from polyacrylic reactors containing two chambers, which were separated by an ion-exchange membrane and equipped with three electrodes.

Highlights

- Researchers from the Biological Systems Unit at the Okinawa Institute of Science and Technology Graduate University have created a system to treat both raw and aerated wastewater.

- The system relies on bacterial communities to break down organic material from raw wastewater and remove nitrate together with phosphate from aerated wastewater.

- It is easy to assemble and low maintenance.

- A proof-of-concept have been shown to work in both the lab and on a local swine farm in Okinawa, Japan.

Anyone who lives in Okinawa, a subtropical island in Japan, has an appreciation of the intensity of its pig farming industry. The farms have a large effect on the island’s economy and culture. According to Japan’s Cabinet Office, as of 2018, there were over 225,000 pigs in Okinawa. Pork is a staple in the local diet and is found in many dishes in traditional restaurants. But the presence of the pig farms has another, less welcome, impact – the odor-y kind. Drive through some particularly farm-filled areas with the car’s windows wound down and you’re sure to be filled with regret.

This smell is, at least in part, caused by a byproduct of the pig farming. Across Okinawa, large amounts of wastewater are produced by the farms. Now, researchers from the Biological Systems Unit at the Okinawa Institute of Science and Technology Graduate University (OIST) have created a new system for treating this wastewater, which they’ve successfully tested on a local swine farm in Okinawa.

“Our new system uses two different chambers,” explained Dr. Anna Prokhorova, lead author of a paper recently published in Bioresource Technology. “In the one chamber, full strength swine wastewater is treated for the removal of odor, pathogens, and organic matter, whereas in the other chamber, excess nitrate and phosphate is removed from wastewater that has already been treated through the traditional aeration system. To the best of our knowledge, this is the first system to successfully treat two different types of wastewater at the same time.”

This is a stark contrast to the traditional aeration system currently utilized by farmers which mainly treats organic matter in the wastewater and also converts the ammonium present to nitrate but does not treat the nitrate further. In Japan, the nitrate discharge limit for the livestock industry will soon be lowered to one fifth of the current level (which today sits at 500 milligrams of nitrate-nitrogen per liter) to be in line with other industries. More than 35% of farms in Okinawa are likely to exceed this impending change.

“This is of huge concern because nitrate contamination can have disastrous impacts on both human health and the environment,” said Dr Mami Kainuma, group leader in the Biological Systems Unit. “When nitrate is ingested by people, it is converted to nitrite, which impacts the bloods’ ability to carry oxygen and can lead to methemoglobinemia or blue baby syndrome.”

Original Article: Value from sewage? New technology makes pig farming more environmentally friendly

More from: Okinawa Institute of Science and Technology

The Latest Updates from Bing News & Google News

Go deeper with Bing News on:

Value from sewage

- How Sewage Is Helping Along the Energy Transition

Cities, utilities and buildings are increasingly turning to some unlikely renewables to reduce fossil fuel emissions.

- Shellfish industry on a 'knife edge' as sewage dumped in designated waters for 192,000 hours last year

Human sewage can carry diseases and viruses like e.coli and norovirus, although molluscs are then soaked in sterile tanks so they can usually purify themselves before they are sold.

- Sewage smell in South Bay keeps people up at night

The sewage smell in the South Bay has been so bad in the last couple of days that people tell ABC 10News it has been keeping them up at night.

- How Much Does It Cost to Clean a Septic Tank? (2024 Guide)

Learn More › Highlights On average, the cost to clean a septic tank ranges between $250 to $550, with a national average cost of $400. Septic tank cleaning costs are made up of several factors, some ...

- 'Stitch up' for shellfish industry as sewage dumped in designated waters for 192,000 hours last year

Untreated sewage was released into designated shellfish waters for ... "stitch-up" because it pushes up producers' electricity and labour costs, and reduces the value of their catch, for which they ...

Go deeper with Google Headlines on:

Value from sewage

[google_news title=”” keyword=”value from sewage” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]

Go deeper with Bing News on:

Wastewater treatment

- Hinesburg moving forward with wastewater plant construction

HINESBURG, Vt. (WCAX) - Plans are moving forward in Hinesburg to replace its wastewater treatment facility. The town’s current wastewater discharge doesn’t meet state standards. They’ve been trying to ...

- Marquette wastewater treatment facility upgrades continue

Wednesday morning, local leaders toured the Marquette Area Wastewater Treatment facility and celebrated the work of new projects to protect the vital resource.

- Studies assess feasibility of aquaculture wastewater treatment methods

In the 2023 study, Simsek and his co-authors evaluated electrocoagulation (EC) and electrooxidation (EO) treatments of shrimp wastewater, both separately and together. EC and EO, widely used methods ...

- Veolia and Milwaukee recognize wastewater infrastructure as an “Ecofactory”

Veolia and the state of Milwaukee recognize Milwaukee’s wastewater treatment infrastructure as an “Ecofactory.” ...

- Sheep control plant and weed growth at Merced wastewater treatment plant. Why it’s important

More than 900 sheep are being used to graze on the land and control plant and weed growth over about 80 acres in Merced.

Go deeper with Google Headlines on:

Wastewater treatment

[google_news title=”” keyword=”wastewater treatment” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]