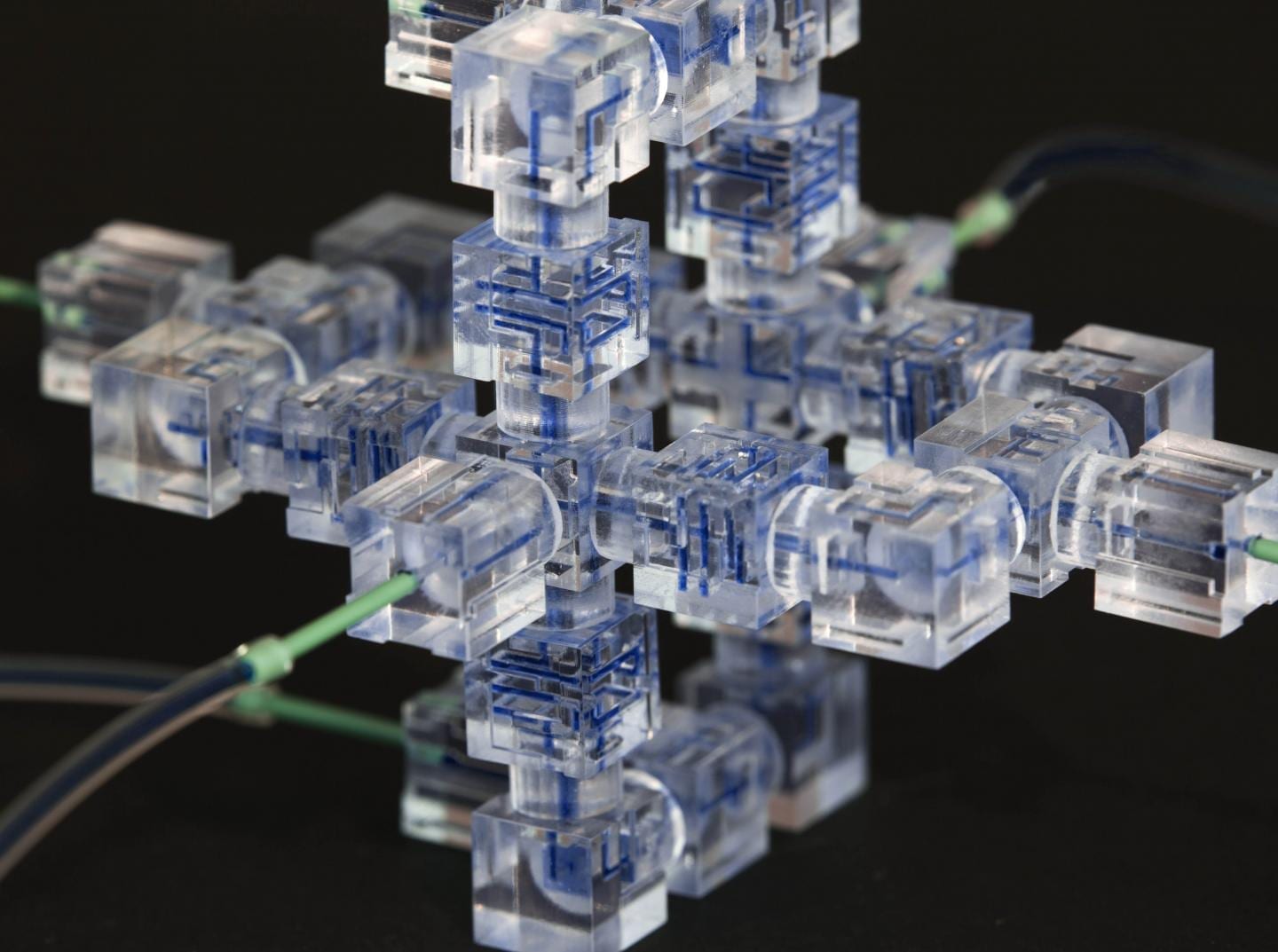

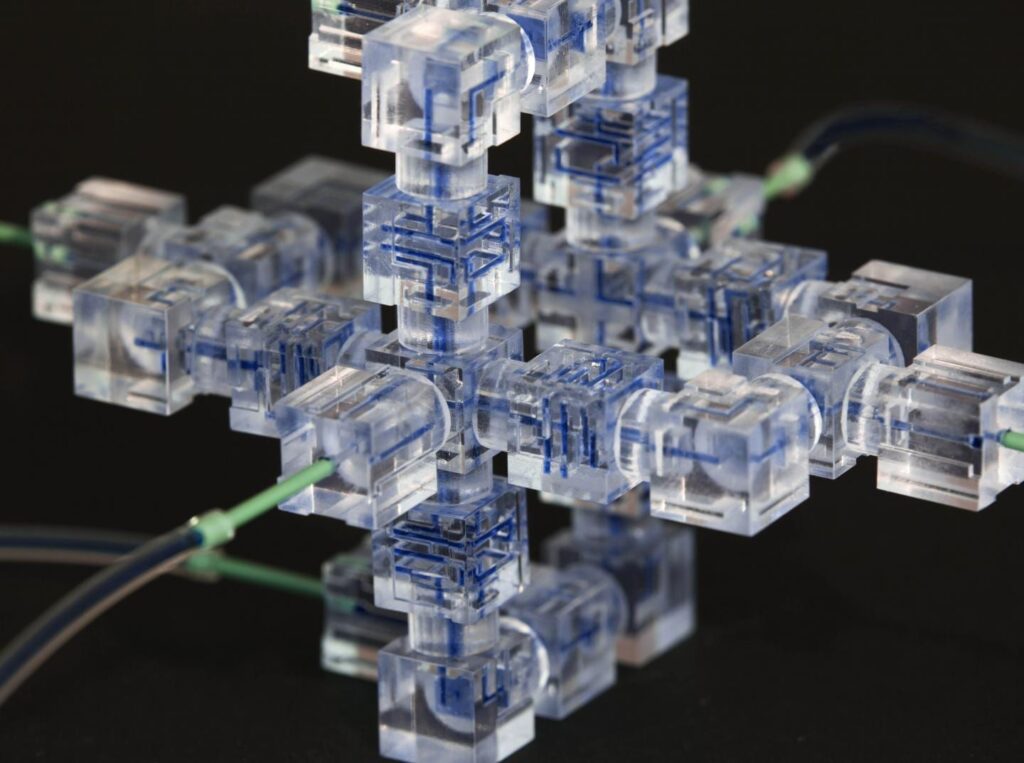

Credit: USC Viterbi School of Engineering

Newly developed modular components take microfluidic system construction from flat to 3-D and make it cheap, quick and easy

Thanks to new LEGO®-like components developed by researchers at the USC Viterbi School of Engineering, it is now possible to build a 3-D microfluidic system quickly and cheaply by simply snapping together small modules by hand.

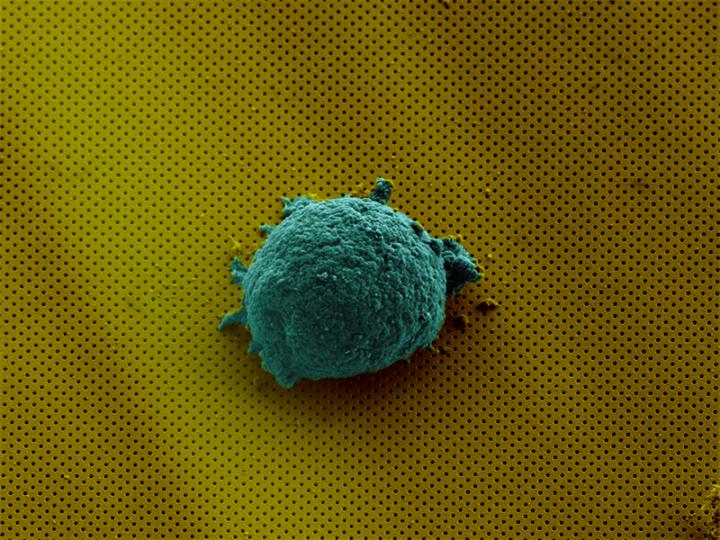

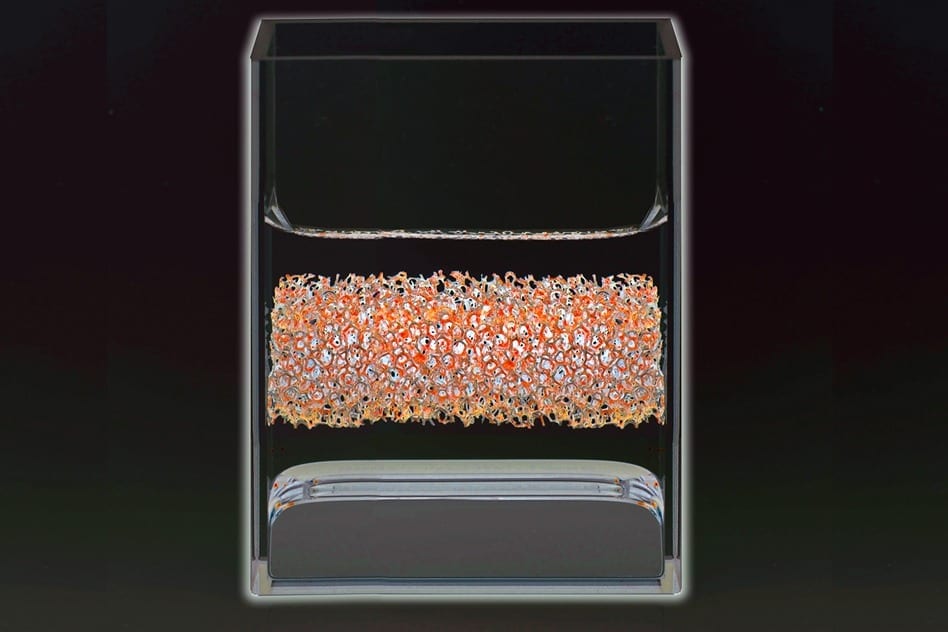

Microfluidic systems are used in many fields including engineering, chemistry and biotechnology to precisely manipulate small volumes of fluids for use in applications such as enzymatic or DNA analysis, pathogen detection, clinical diagnostic testing, and synthetic chemistry. Traditionally, microfluidic devices are built in a cleanroom on a two-dimensional surface using the same technology developed to produce integrated circuits for the electronics industry.

Though tiny, designing, assembling and testing a new microfluidics system can take a lot of time and money. Building a single device can often require multiple iterations, each of which can take up to two weeks and several thousand dollars to manufacture. And the more complex the system, the higher the number of iterations needed.

“You test your device and it never works the first time,” said Krisna Bhargava, materials science graduate student at the USC Viterbi School of Engineering. “If you’ve grown up to be an engineer or scientist, you’ve probably been influenced by LEGO® at some point in your childhood. I think every scientist has a secret fantasy that whatever they’re building will be as simple to assemble.”

Frustrated that reproducing a simple microfluidic circuit could cost him so much time and money, Bhargava set out simplify the construction process. First, he identified the primitive elements commonly used in microfluidic systems, much like how circuitry is broken down in electrical engineering. Basic microfluidic functions would be separated into standardized modular components, not an entirely revolutionary concept. But then, he abandoned the two-dimensional method of building microfluidic devices altogether.

“The founders of the microfluidics field took the same approach as the semiconductor industry: to try to pack in as much integrated structure as possible into a single chip,” explained Bhargava. “In electronics, this is important because a high density of transistors has many direct and indirect benefits for computation and signal processing. In microfluidics, our concerns are not with bits and symbolic representations, but rather with the way fluidics are routed, combined, mixed, and analyzed; there’s no need to stick with continuing to integrate more and more complex devices.”

Borrowing an approach from the electronics industry, which uses prototype boards to build circuits, Bhargava conceived of three-dimensional modular components that encapsulated the common elements of microfluidic systems, as well as a connector that could join the separate components together. Inspired by recent advancements in micron-scale 3D-printing, he and a USC Viterbi research team that included chemical engineering and materials science professor Noah Malmstadt and biomedical engineering graduate student Bryant Thompson, designed computer models for eight modular fluidic and instrumentation components (MFICs, pronounced “em-fix”) that would each perform a simple operation. Examples are a “helix” component that can mix two fluid streams and a component that contains an integrated optical sensor for measuring the size of small droplets. The components constructed for this study are approximately 1 cm3, slightly smaller than a standard 6-sided die.

The team’s development of these MFICs represents the first attempt to break a device into separate components that can be assembled, disassembled and re-assembled over and over.

“What we’ve built looks more like a hobby breadboard,” said Malmstadt. “You can build a circuit on the cheap with your bare hands.”

The team attributes much of the success in the fabrication stage to recent advancements in high-resolution 3-D printing.

“We got the parts back from our contract manufacturer and on the first try they worked out better than I could have dreamed. We were able to build a working microfluidic system that day, as simple as clicking LEGO® blocks together,” said Bhargava.

The Latest on: Lab-on-a-chip

[google_news title=”” keyword=”Lab-on-a-chip” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Lab-on-a-chip

- MIT’s new powerful phone chip thwarts millions of data theft attacks in testson April 23, 2024 at 11:17 am

A team of researchers from MIT and the MIT-IBM Watson AI Lab has developed a new chip to make health-monitoring apps more secure. These new machine-learning accelerator chips aim to enhance data ...

- Which Lab Should You Go To First In Grounded?on April 22, 2024 at 4:23 am

To craft a Gas Mask, you’ll need a Weevil Gnose, Gnat Fuzz, Crude Rope, and a Stinkbug Part. The Stinkbug Part is the hardest piece to get, as Stinkbugs can be strong early-game enemies that require ...

- Mini brains and lab-on-a-chip wearables: Jumar Bioincubator officially begins its mission to build "Australia's next CSL"on April 17, 2024 at 5:00 pm

Ovulation bio-sensing startup Symex Labs has developed a wearable "lab-on-a-chip" solution that provides continuous "set-and-forget" monitoring of hormones to more conveniently and effectively predict ...

- New diagnostic tool achieves accuracy of PCR tests with faster and simpler nanopore systemon April 8, 2024 at 12:04 pm

The nanopore optofluidic chip used in the new diagnostic system, with a PCR thermocycler in the background for comparison. The new system could easily fit into a researcher’s lab or clinician ...

- A Lab-on-a-Chip for the Concurrent Electrochemical Detection of SARS-CoV-2 Nucleic Acids and Anti-SARS-CoV-2 Antibodies in Salivaon March 26, 2024 at 4:00 am

This presentation describes the development and application of a 3D-printed lab-on-a-chip that concurrently detects, via multiplexed electrochemical outputs and within 2 h, SARS-CoV-2 RNA in saliva as ...

- An Introduction to Lab-on-a-Chip Technology in Clinical Diagnostics: Successes and Remaining Challengeson March 26, 2024 at 12:00 am

Lab-on-a-chip platforms enable advanced processing, manipulation, and analysis of biological samples in miniaturized fluidic devices. Despite the numerous advantages, such as lower reagent and sample ...

- Lab on a Chip News and Researchon November 1, 2023 at 5:00 pm

Researchers described the development and applications of a 3D-printed lab-on-a-chip device that quickly detected the presence of SARS-CoV-2 in patient's saliva. A University of Texas at Arlington ...

- Particle Accelerator… On A Chipon October 30, 2023 at 5:06 am

you usually think of some giant cyclotron with heavy-duty equipment in a massive mad-science lab. But scientists now believe they can create particle accelerators that can fit on a chip smaller ...

- Lab on a Chipon October 18, 2023 at 9:17 am

These must represent a significant development in the particular field, and are judged according to originality, quality of scientific content and contribution to existing knowledge. Although there is ...

- New approach to complete automation in sizing and quantitation of DNA and proteins by the Automated Lab-on-a-Chip Platform from Agilent Technologieson October 25, 2022 at 9:48 am

The newly introduced Agilent 5100 Automated Lab-on-a-Chip Platform (ALP) offers a high-throughput system to overcome the limitations of slab gel analysis in protein and DNA sizing and quantitation.

via Bing News