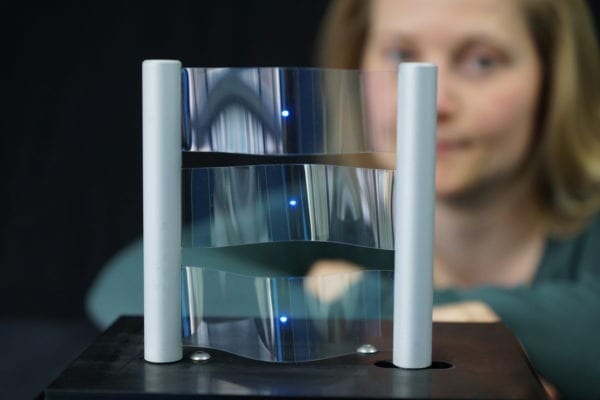

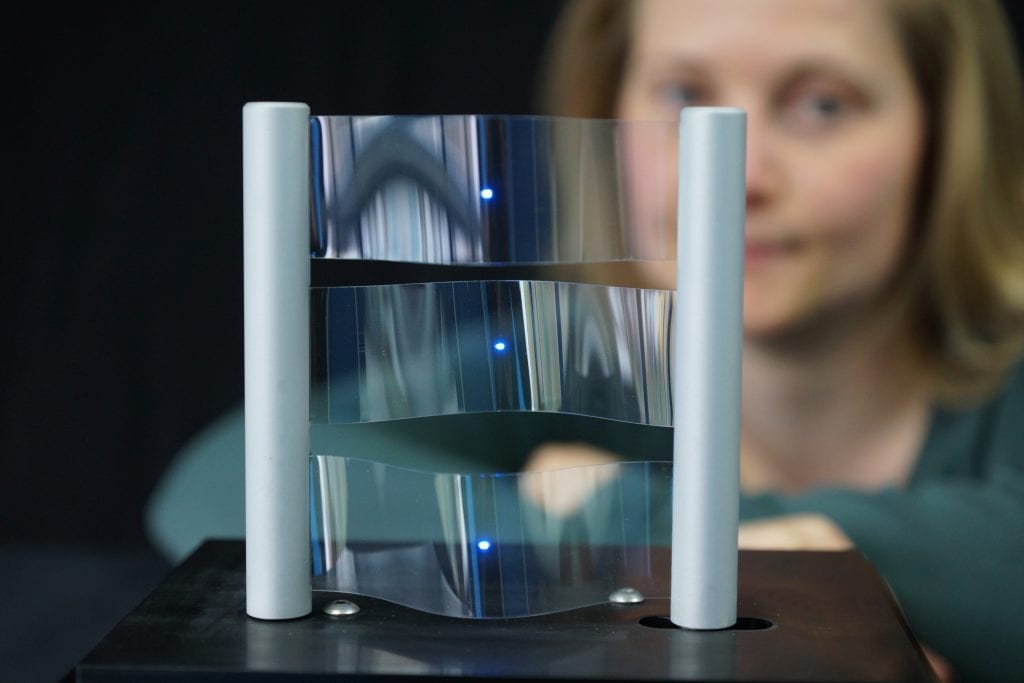

The INM will be presenting flexible touch screens, which are printed on thin plastic foils with recently developed nanoparticle inks, using transparent, conductive oxides (TCOs).

Mobile phones and smart phones still haven‘t been adapted to the carrying habits of their users. That much is clear to anyone who has tried sitting down with a mobile phone in the back pocket: the displays of the innumerable phones and pods are rigid and do not yield to the anatomical forms adopted by the people carrying them. By now it is no longer any secret that the big players in the industry are working on flexible displays. How to produce suitable coatings for those cost-efficiently will be demonstrated by INM – Leibniz-Institute for New Materials at stand B46 in hall 2 at this year’s Hannover Messe as part of the leading trade fair for R & D and Technology Transfer which takes place from 25th to 29th April.

The INM will be presenting flexible touch screens, which are printed on thin plastic foils with recently developed nanoparticle inks, using transparent, conductive oxides (TCOs). These inks are suitable for a one-step printing process. Thus transparent lines and patterns are obtained by inkjet printing or alternatively by direct gravure printing, which are electrically conductive even after bending. Thus, a one-step-printing process for cost-efficient TCO structures is enabled.

Conductive coatings with TCOs are usually applied by means of high vacuum techniques such as sputtering. For patterning of the TCO coatings additional cost-intensive process steps are necessary, for example photolithography and etching.

“We use the TCOs to produce nanoparticles with special properties,” explains Peter William de Oliveira, Head of the Optical Materials Program Division. “The TCO ink is then created by adding a solvent and a special binder to these TCO particles. The binder performs several tasks here: it not only makes the TCO nanoparticles adhere well on the substrate; it also increases the flexibility of the TCO coating: in this way, the conductivity is maintained even when the films are bent”.

The ink can be applied to the film directly by inkjet or gravure printing. After curing under UV light at low temperatures less than 130 degrees centigrade, the coating is completed.

The transparent, electronically conductive inks allow conductor tracks to be produced unproblematically even on a large scale by means of classic reel-to-reel processes. Initial trials at INM have been promising. The researchers all agree that the use of structured rollers will in the future allow large, structured conductive surfaces to be printed with a high throughput at low cost.

Learn more: INKJET PROCESS TO PRINT FLEXIBLE TOUCHSCREENS COST-EFFICIENTLY

The Latest on: Flexible touch screens

[google_news title=”” keyword=”Flexible touch screens” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Flexible touch screens

- 13 unique Mother's Day gifts for every type of momon April 29, 2024 at 10:22 am

Content. Mother's Day is a time to honor and celebrate the special women in our lives who have shaped us with their love, wisdom, and guidance.

- Flexible Electronics: Transforming Cars, Homes, and Healthcareon April 28, 2024 at 6:31 pm

Imagine a car interior with sleek touch panels and heated windows, or a home where lights respond to your presence and fridge labels warn you about spoiled ...

- Insta360 X4 review: A significant step forward for consumer 360 videoon April 26, 2024 at 2:13 am

There's a new 360 camera on the block, and it promises a big increase in resolution and quality. We take a look at Insta360's new X4 to see if it really is worth the upgrade.

- Screen’s new JET 560HDX roll-fed digital inkjet press and more premieres at drupa 2024on April 25, 2024 at 6:16 pm

It was drupa 2008 when the world first saw Screenʼs commercial introduction of its first entry into inkjet digital printing – the Truepress Jet520.

- Global Touch Screen Industry Report 2024-2028: Rising Adoption of Flexible and Foldable Touchscreen Displayson April 24, 2024 at 8:52 am

The "Global Touch Screen Market 2024-2028" report has been added to ResearchAndMarkets.com's offering.The touch screen industry is poised for remarkable expansion, with an anticipated compound annual ...

- Global Touch Screen Industry Report 2024-2028: Rising Adoption of Flexible and Foldable Touchscreen Displayson April 24, 2024 at 4:52 am

Innovations and Opportunities Industry growth is further fueled by the advent of flexible and foldable touch screen displays, a sector poised for significant development. Increasing innovation in ...

- Interactive Display Market Guiding the Ship Strategies for Navigating the Audience Odysseyon April 21, 2024 at 8:25 pm

Request To Download Free Sample of This Strategic Report @- Interactive Display Market was valued at $14.63 billion in 2018, and is projected to reach $29.19 billion by 2026, registering a CAGR of 8.

- Loupedeck CT Is The Ultimate Productivity Tool For Creativeson April 21, 2024 at 3:00 am

This beautifully made device connects to PC or Macs and provides almost endless shortcuts and customizable buttons for getting the most from creative software.

- New flexible working regs: kicking companies into touch or simply out of touch?on April 7, 2024 at 5:00 pm

As companies gear up for the implementation of the Flexible Working (Amendments) Regulation, which stared on Saturday (6 April), it's time to address the elephant in the room: does this legislation ...

- How will the new flexible working rules affect us?on April 2, 2024 at 2:18 am

Q: How should I handle flexible working requests from employees after the new changes take effect on April 6? A:When you hear the words “flexible working”, most people these days would assume ...

via Bing News