New research shows how inkjet-printing technology can be used to mass-produce electronic circuits made of liquid-metal alloys for “soft robots” and flexible electronics.

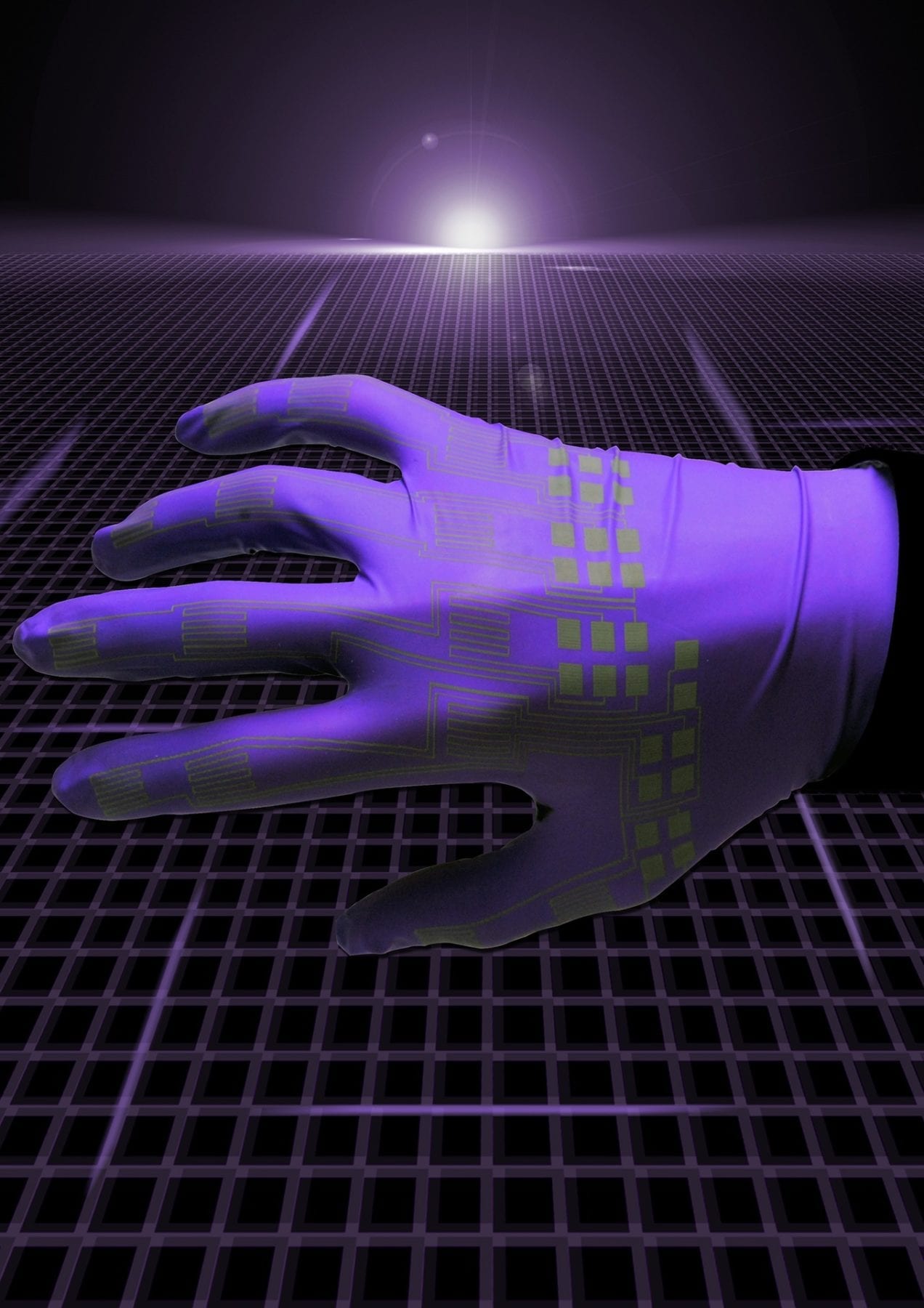

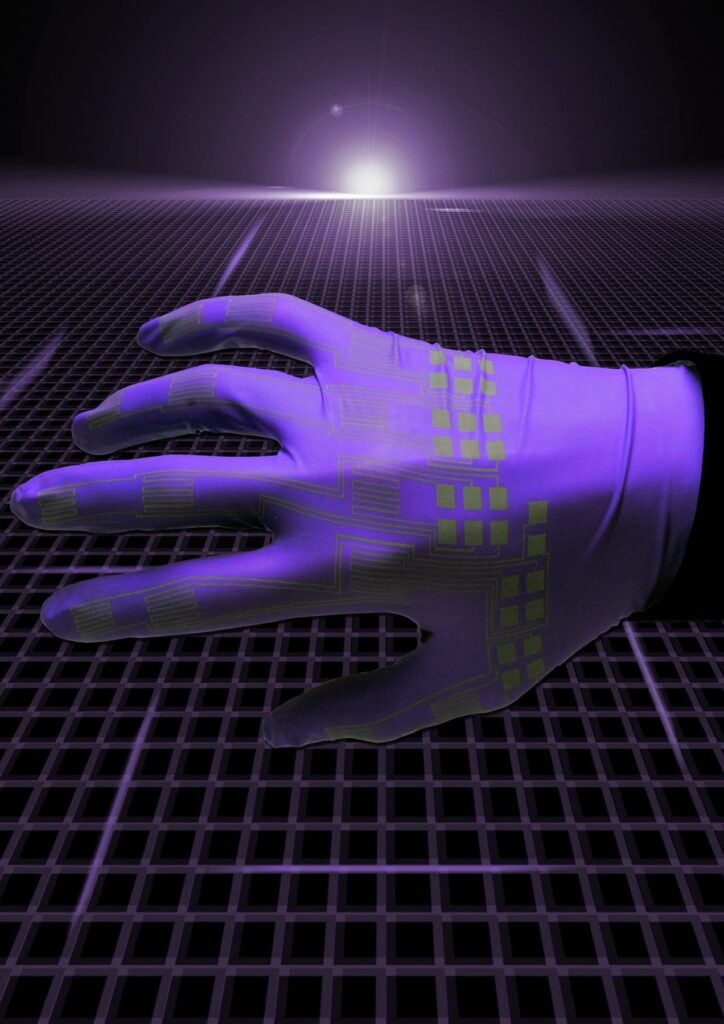

Elastic technologies could make possible a new class of pliable robots and stretchable garments that people might wear to interact with computers or for therapeutic purposes. However, new manufacturing techniques must be developed before soft machines become commercially feasible, said Rebecca Kramer, an assistant professor of mechanical engineering at Purdue University.

“We want to create stretchable electronics that might be compatible with soft machines, such as robots that need to squeeze through small spaces, or wearable technologies that aren’t restrictive of motion,” she said. “Conductors made from liquid metal can stretch and deform without breaking.”

A new potential manufacturing approach focuses on harnessing inkjet printing to create devices made of liquid alloys.

“This process now allows us to print flexible and stretchable conductors onto anything, including elastic materials and fabrics,” Kramer said.

A research paper about the method will appear on April 18 in the journal Advanced Materials. The paper generally introduces the method, called mechanically sintered gallium-indium nanoparticles, and describes research leading up to the project. It was authored by postdoctoral researcher John William Boley, graduate student Edward L. White and Kramer.

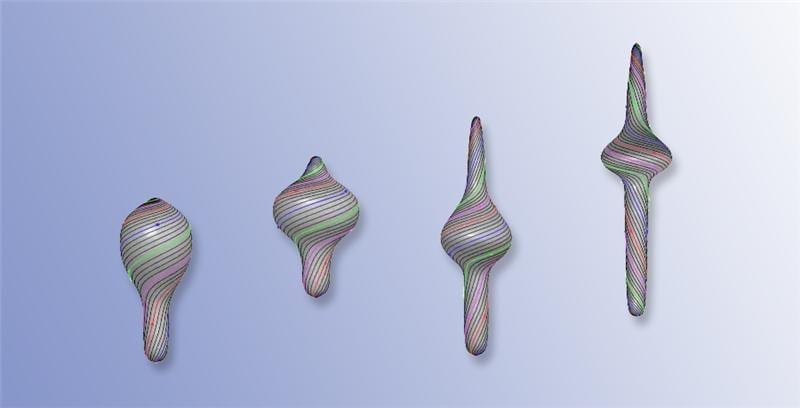

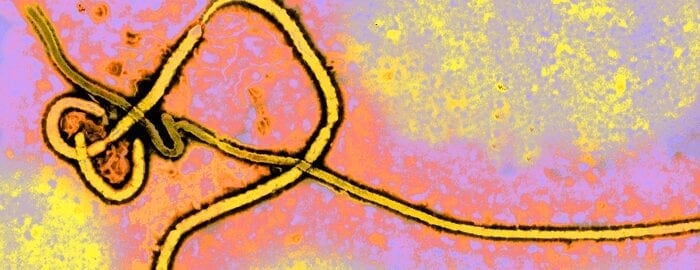

A printable ink is made by dispersing the liquid metal in a non-metallic solvent using ultrasound, which breaks up the bulk liquid metal into nanoparticles. This nanoparticle-filled ink is compatible with inkjet printing.

“Liquid metal in its native form is not inkjet-able,” Kramer said. “So what we do is create liquid metal nanoparticles that are small enough to pass through an inkjet nozzle. Sonicating liquid metal in a carrier solvent, such as ethanol, both creates the nanoparticles and disperses them in the solvent. Then we can print the ink onto any substrate. The ethanol evaporates away so we are just left with liquid metal nanoparticles on a surface.”

After printing, the nanoparticles must be rejoined by applying light pressure, which renders the material conductive. This step is necessary because the liquid-metal nanoparticles are initially coated with oxidized gallium, which acts as a skin that prevents electrical conductivity.

“But it’s a fragile skin, so when you apply pressure it breaks the skin and everything coalesces into one uniform film,” Kramer said. “We can do this either by stamping or by dragging something across the surface, such as the sharp edge of a silicon tip.”

The approach makes it possible to select which portions to activate depending on particular designs, suggesting that a blank film might be manufactured for a multitude of potential applications.

“We selectively activate what electronics we want to turn on by applying pressure to just those areas,” said Kramer, who this year was awarded an Early Career Development award from the National Science Foundation, which supports research to determine how to best develop the liquid-metal ink.

The process could make it possible to rapidly mass-produce large quantities of the film.

Read more: Inkjet-printed liquid metal could bring wearable tech, soft robotics

The Latest on: Inkjet-printed liquid metal

[google_news title=”” keyword=”Inkjet-printed liquid metal” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Inkjet-printed liquid metal

- Best photo printers of 2024on April 25, 2024 at 8:52 am

If you're looking for a top-rated photo printer, we recommend the best inkjet printers. Using liquid ink ... and studio photography printing. But with so many options on the market, from standard ...

- Liquid-metal transfer from anode to cathode without short circuitingon April 11, 2024 at 7:31 am

The bubble layer with critical thickness of 250 µm plays a dominating role to protect the liquid metal from short-circuiting and facilitate the smooth detachment and transfer process, while the ...

- Inkjet-Printed IGZO Memristors: A Leap in Neuromorphic Computingon April 9, 2024 at 10:26 am

In an article published in the journal Scientific Reports, researchers investigated and demonstrated the volatile and non-volatile switching behaviors of inkjet-printed Indium-Gallium-Zinc Oxide ...

- Two-photon fabricationon April 5, 2024 at 1:29 am

Classic 3D prototyping techniques, such as UV laser stereolithography and 3D inkjet printing, can also reproduce ... 3D nonlinear photonic devices, and metal-binding chemical groups could be ...

- Epson launches latest heat-free line inkjet printing to the A4 print marketon April 4, 2024 at 5:00 pm

Epson has continued its drive to bring heat-free line inkjet technology through its office print range, launching the AM-C400 and AM-C550 MFPs to deliver improved solutions to the A4 market. These new ...

- Liquid Metal: A Transformative Material for Nanotechnology Applicationson March 17, 2024 at 9:01 am

Liquid metal refers to a class of metallic materials that remain in a liquid state at or near room temperature. These materials possess unique properties, such as high electrical and thermal ...

- Inkjet paves the way for the future of printon June 22, 2023 at 5:26 pm

Advances in print technology have helped bring digital printing to the tipping point – and inkjet innovation is what’s driving it Printing has a long history of development and innovation: from ...

- From metal to liquid, this shapeshifting robot can escape a cageon January 30, 2023 at 4:00 pm

This newsletter may contain advertising, deals, or affiliate links. Subscribing to a newsletter indicates your consent to our Terms of Use and Privacy Policy. You may ...

- Full Color 3D Printing With The Help Of An Inkjet Headon December 4, 2021 at 2:45 am

Note the dual vertical assemblies – one carrying the extruder, the other carrying an inkjet print head. The hack is simple, consisting of a second vertical frame added on to the printer.

- A Decade In Development, Liquid-Metal Batteries By Ambri May Soon Change The Energy Storage Gameon September 2, 2021 at 5:44 am

“And it was the Masters and PhD thesis work of David Bradwell. They formed a liquid metal battery company after receiving one of the first ARPA-E grants for the MIT research, and received ...

via Bing News