While the pattern for making a wearable fabric battery has already been laid out, it’s now time to select the threads that will turn a textile into an energy storage device.

That process is being driven by Drexel University doctoral student Kristy Jost, who’s threaded her way into the forefront of research on conductive yarns.

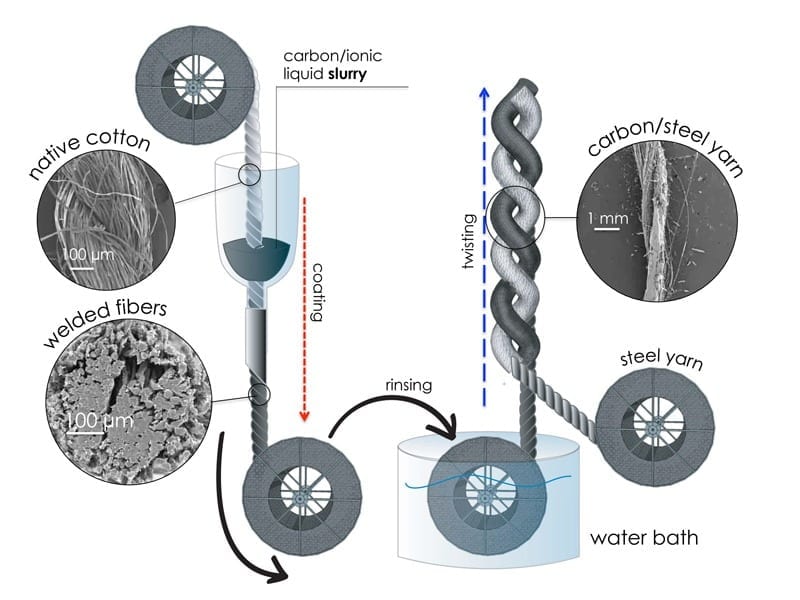

Using a process, called “Natural Fiber Welding,” which was developed by collaborator Paul C. Trulove at the U.S. Naval Academy, researchers are embedding functionalized materials—at the molecular level—into a cellulose-based yarn, like cotton. Jost, who is advised by Yury Gogotsi, PhD, Distinguished University and Trustee chair professor in the College of Engineering and Genevieve Dion, director of the Shima Seiki Haute Technology Laboratory and an assistant professor in the Antoinette Westphal College of Media Arts & Design, has taken this process to the next level. She and her team are using NFW to strategically alter yarn for a variety of uses, but the one they’re most interested in is energy storage.

“If energy textiles are going to be realized, figuring out the best way to functionalize our yarn is the first step,” Jost said. “Natural fiber welding is proving to be highly effective in producing yarns that we can tune for particular uses, including energy storage. This work is only possible because of the successful collaboration between Drexel’s Shima Seiki Haute Tech Laboratory, the A.J. Drexel Nanomaterials Institute, and the chemistry department at the U.S. Naval Academy.

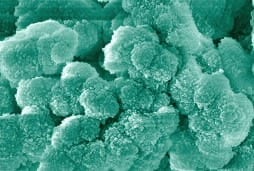

To make it happen, the yarn is first treated with a molten salt, which causes the polymer chains to swell, thus opening the structure. Then they embed it with a functional material—such as activated carbon particles—by sliding the yarn through a syringe filled with a mixture of the material in the ionic liquid. The yarn is then pulled through the needle of the syringe, which physically presses the carbon into the fibers, and it is wrapped onto a spool. The ionic liquid is removed by washing the yarn with water, which also re-solidifies the cotton fiber, trapping carbon particles in the surface.

The result is a complex composite fibrous material that retains its original flexibility, but gains the capacitive properties of activated carbon. Much like conventional energy storage devices have metal plates to improve the electrical conductivity, the activated carbon-natural fiber welded yarn is twisted with a highly conductive stainless steel yarn prior to testing. Activated carbon on it’s own is not conductive enough for energy applications, so the stainless steel yarn allows the materials to be charged more easily.

“What’s unique about this process, is that we can use any commercially available yarn made of cellulose—cotton, linen, bamboo, viscose, rayon,” Dion said. “This adds another level of tune-ability, since we can weld thick or fine yarns, containing longer or shorter fibers, which can lead to textiles with unique mechanical properties. We use activated carbon for much of our research because it tends to be skin-friendly, and is commonly found in water filters. The yarn could be embedded with a variety of carbon nanomaterials, but we’re looking ahead at making a wearable garment, so concerns like skin irritation, come into play.”

Read more: Holding Energy By The Threads: Drexel Researchers Spin Cotton Into Capacitive Yarn

The Latest on: Capacitive Yarn

[google_news title=”” keyword=”Capacitive Yarn” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Capacitive Yarn

- Guilderland yarn shop celebrates expansionon April 24, 2024 at 9:35 am

A local yarn company is celebrating its grand reopening. CeCe’s Wool in Guilderland’s Hamilton Square Plaza held a ribbon-cutting on Wednesday. The business, which opened five years ago ...

- Apple's iPhone 16 could finally get the capacitive buttons that the iPhone 15 missed out on with a supplier now lined upon April 22, 2024 at 10:48 am

There were rumors last year that the iPhone 15 would ditch its clicky buttons in favor of new capacitive ones that would react to being touched. The prospect immediately reminds me of the iPhone 7 ...

- Rumor: iPhone 16 could ditch physical buttons after allon April 22, 2024 at 6:45 am

Rumors that Apple is hoping to switch a future iPhone model from physical to capacitive buttons persist. Now, a new supply chain report suggests that Apple has placed a supply chain order for a ...

- Apple's Button-Free iPhone Plans Resurface: New Order Hints at 2024 Changeon April 21, 2024 at 5:00 pm

Instead, use capacitive buttons for the power and volume rocker. Recently, a new supply chain report detailed that Apple has placed an order for a new capacitive button system that would likely ...

- capacitive sensoron November 27, 2023 at 4:00 pm

There are a bunch of ways to go about it, and this capacitive rainmeter solution from [Magnus Thome] might just be the perfect solution you’re looking for. Like many who came before ...

- iPhone 15 and 15 Plus might feature capacitive buttons like the Proson April 10, 2023 at 3:50 am

Apple will move from physical buttons to capacitive buttons on these devices, which will resemble the functionality of the trackpad on MacBooks. Taptic Engines will provide haptic feedback ...

- iPhone 15 Pro capacitive buttons will work with cases and gloveson March 31, 2023 at 3:50 am

Instead, we’re getting solid-state capacitive buttons that will work just like the trackpad on MacBooks. You won’t be able to press them like physical buttons. But Taptic Engines will give you ...

- Meet our Teamon September 9, 2019 at 9:59 am

Richard is currently working on developing textile capacitive touch sensors at CFF for applications ... Lingyi is a PhD student working on developing functional fibers, yarns and fabrics by ...

- Textile Energy Storageon October 1, 2018 at 6:39 pm

We are currently investigating the incorporation of spun carbon fiber yarn into a knit architecture to fully integrate super-capacitor devices directly into textiles. The Capacitive Touch Sensor (CTS) ...

via Bing News