Super-resilient material is the first to combine strength and toughness

A metal alloy masquerading as a glass is the first material to be fabricated that is as strong and as tough as the toughest steel. The feat could eventually see such materials replace steel in buildings, cars or bridges.

The terms ‘strength’ and ‘toughness’ may be used almost interchangeably in everyday life, but until now, no materials have been found that display both these characteristics. Some materials, such as glass, are strong — that is, they are scratch-resistant and it is difficult to permanently bend them out of shape when you place a heavy load on them — but they also tend to be brittle. Others, such as metal, are tough — that is, they are more difficult to shatter — but they are generally more malleable.

“The challenge has always been to achieve both high strength and toughness,” says Marios Demetriou, a materials scientist at the California Institute of Technology in Pasadena. “But until now we have always had to compromise between the two.”

Demetriou and his colleagues have developed an alloy that combines the best features of both by turning to ‘amorphous metals’. Their work is published in Nature Materials today.

Strength in weakness

Normal metals are weak and malleable because their atoms are lined up in a crystalline structure and easily slip past each other when placed under a heavy load. Amorphous metals are stronger. They are made by rapidly cooling molten metal, so that its atoms are stuck in a disordered arrangement — resembling the structure of glass. It takes much more energy to permanently shift these atoms around.

Unfortunately, for a long time these ‘glassy metals’ also seemed to be inherently brittle. This is because they contain small defects that can clump together into bands, as the material begins to fail, says Demetriou. These bands can rapidly turn into cracks, and the material shatters.

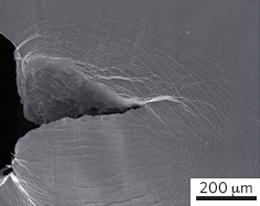

However, materials scientists now know that, ironically, generating an extremely large number of these bands could have the opposite effect — making the material tougher. “If you dramatically amplify the number of bands, they start to interlace and form networks,” says Demetriou. “When new cracks evolve in the glassy metal, these networks cluster around the crack tips, blocking them from growing.”