At a General Electric factory in Schenectady, N.Y., tens of thousands of tiny sensors are quietly collecting data about each step in the manufacturing of a battery.

The sensors know, for instance, how humid the factory floor was on a certain production day, and exactly how much pressure a machine applied to a particular battery component. If polymer parts come out slightly thicker one day compared with another, sensors communicate this to the operator, who can examine stats from the two days.

The company is gathering this data so it can improve its factories, determining which conditions — down to the surrounding temperature — are associated with the best products. GE is also trying to realize chief executive Jeff Immelt’s vision of the “brilliant factory”: a dynamic system in which machine parts constantly relay information to operators, who can schedule maintenance before equipment fails, all the while improving the manufacturing process. GE soon plans to use 3-D printers in new factories to customize and print new components, such as metal jet engine parts or plastic tools.

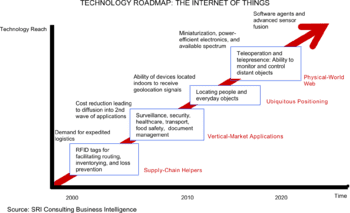

This is GE’s version of the “Internet of Things,” a term often applied to a connected network of smartphones and home appliances; GE executives call it the “Industrial Internet.”

Read more . . .

The Latest on: Industrial Internet

[google_news title=”” keyword=”Industrial Internet” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Industrial Internet

- Wall Street Loves This 7.08% Dividend Stock and So Will Passive Income Investorson April 30, 2024 at 2:14 pm

A by-product of both the development of urban cities and the expansion to the Pacific Coast during the 1800’s was the introduction of packaged foods. B&G Foods, Inc. (NYSE: BGS) is an American company ...

- Eaton raises 2024 profit forecast on strong industrial equipment demandon April 30, 2024 at 4:05 am

Eaton raised its full-year profit forecast, after beating analysts' expectations for the first quarter on Tuesday, betting on resilient demand for industrial equipment amid the U.S. government's ...

- Industrial IoT: Transforming Manufacturing Processeson April 29, 2024 at 8:21 pm

The rise of emerging technologies and Internet of Things (IoT) applications in industrial systems is facilitating the development of Industrial IoT (IIoT). In the industrial sector, IIoT serves as a ...

- More buildings to be demolished at industrial estateon April 28, 2024 at 7:26 am

In recent months, the city council has approved a number of applications to remove buildings at the estate, according to the Local Democracy Reporting Service. These included factory units and a ...

- Russians attack industrial facility in Zaporizhzhyaon April 28, 2024 at 6:52 am

Head of Zaporizhzhya Regional Military Administration Ivan Fedorov said that Russians attacked an industrial facility in city on 1:37 p.m. EET. According to him, there were no casualties, and ...

- Industrial IoT (IIoT) Global Market Report 2024-2028: Standardization of Internet Protocol Version 6 (IPv6) Drives Market Growthon April 25, 2024 at 4:00 am

Dublin, April 25, 2024 (GLOBE NEWSWIRE) -- The "Industrial IoT (IIoT): Global Markets" report has been added to ResearchAndMarkets.com's offering. The global market for IIoT is estimated to increase ...

- The Dada Era of Internet Memeson April 24, 2024 at 1:45 pm

In some ways, the Donghua Jinlong memes are of a piece with previous generations of Internet humor that proliferated on social platforms. As with, say, LOLcats in the mid-two-thousands, the appeal of ...

- Chinese Exports Are Threatening Biden’s Industrial Agendaon April 18, 2024 at 3:26 pm

The president is increasingly hitting back with tariffs and other measures meant to restrict imports, raising tensions with Beijing.

- Police bust global cyber gang accused of industrial-scale fraudon April 17, 2024 at 4:46 pm

Police have taken down a gang accused of using a technology service that helped criminals use fraudulent text messages to steal from victims. They have arrested 37 people worldwide and are contacting ...

- Innovative Impact: 10 Ways the Internet of Things Redefines Our Worldon April 17, 2024 at 6:24 am

In today’s rapidly evolving technological landscape, the Internet of Things (IoT) stands out as a groundbreaking phenomenon. With its ability to connect devices and enable seamless communication ...

via Bing News