The results are promising

The ‘wonder material’ of modern science now promises all-printed, flexible and transparent graphene devices on more or less any surface

Inkjet technology has been a revolution. First, there is digital image printing, which has become faster and more flexible than anybody imagined (although not necessarily cheaper).

Then came 3D printing in which one layer of material is printed on top of another to build up a three dimensional objects. That’s become a standard way to make complex prototypes while others are using it to ‘print’ different kinds of chocolates, creams and icings.

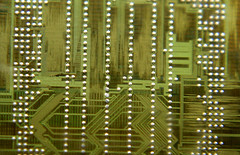

Then there are the groups who have added conducting polymers to the inks and used them to print circuits onto flexible substrates. These are being used to make everything from digital paper to disposable RFID tags. And they can be printed onto sheets of essentially any size, unlike conventional high performance circuitry which must be forged in exotic conditions inside multibillion dollar fabrication plants .

There is a problem however. Inkjet printed electronics underperform conventional integrated circuitry by a significant margin–printed thin film transistors are simply bigger and slower than silicon-based models. So the race is on to improve their performance.

Today, Andrea Ferrari and buddies at the University of Cambridge in the UK show off a significant step forward. These guys have found a way to replace or augment the conducting polymers in these inks with graphene, the wonder-material of the moment.

It’s not hard to see why. The electronic properties of graphene are hard to match and make it idea for nanoelectronics. But the difficulty is combining it into an ink that readily forms small droplets–something that is obviously essential for inkjet printing.

This is essentially the breakthrough that Ferrari and co have achieved. They’ve found a way to readily produced graphene by chemically chipping flakes off a block of graphite and filtering them to remove any that might clog the printer heads.

They then add the flakes to a solvent called N-Methylpyrrolidone, or NMP, which minimises problems such as the coffee ring effect that can occur when some solvents evaporate.

Finally they’ve put this stuff in their printers and printed out a few circuits and thin film transisters.

Read more . . .

Bookmark this page for “graphene electronics” and check back regularly as these articles update on a very frequent basis. The view is set to “news”. Try clicking on “video” and “2” for more articles.