The use of edible films likely will expand dramatically in the future — especially for fruits and vegetables

The scientist who turned fresh-cut apple slices into a popular convenience food, available ready-to-eat in grocery stores, school cafeterias and fast-food restaurants, today described advances in keeping other foods fresh, flavorful and safe for longer periods of time through the use of invisible, colorless, odorless, tasteless coatings.

The overview of these edible films was part of the 246th National Meeting & Exposition of the American Chemical Society (ACS), the world’s largest scientific society. The meeting, which continues through Thursday in the Indiana Convention Center and downtown hotels, features almost 7,000 presentations on advances in science and other topics.

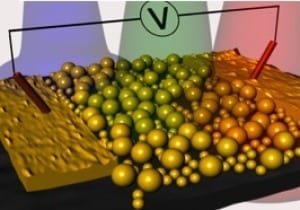

Attila E. Pavlath, Ph.D., pointed out that the use of edible films has grown dramatically since the mid-1980s, when only 10 companies were in the business, to more than 1,000 companies with annual sales exceeding $100 million today. Ready-to-eat fruits and vegetables now account for about 10 percent of all produce sales, with sales exceeding $10 billion annually. The use of edible films likely will expand dramatically in the future — especially for fruits and vegetables — as health-conscious consumers look for more foods that require minimal preparation like cut fruit and premixed salads, he noted.

“Fruits and vegetables have skins that provide natural protection against drying out, discoloration and other forms of spoilage,” Pavlath explained. He is with the U.S. Department of Agriculture’s Western Regional Research Center in Albany, Calif. “Cutting and peeling remove that natural protection, allowing deterioration and spoilage to begin. It’s visible within minutes for foods like apples and bananas, but occurs without any outward sign for other fruits and vegetables. Nature is a very good chemist and we are learning from that and sometimes improving on it with new edible coatings that protect the quality and nutritional value of food.”

Those coatings consist of a thin layer of edible material applied to the surface of a food product to preserve freshness. Apples, for instance, lose some of their natural wax coating during washing after harvest. The replacement is a thin layer of carnauba wax, obtained from the leaves of palm trees. That wax also gives sugar-coated chocolate candy an appealing gloss. Other common edible coatings include starch, alginate, carrageenan, gluten, whey and beeswax.

Pavlath and his group invented the technology that enabled schoolchildren and other consumers to enjoy a new apple treat — refrigerated, packaged apple slices that last 2-3 weeks without turning brown or losing crispness. Apples ordinarily begin to turn brown within 30 minutes after cutting or peeling. Pavlath’s process involves treating freshly cut apple slices with a form of vitamin C, resulting in the first commercial product that retains the desirable characteristics of fresh apples without leaving a detectable residue.

The Latest Bing News on:

Edible coatings

- Market Projections: Carboxymethyl Cellulose Industry Set to Reach US$ 3,073.5 Million by 2033, with a CAGR of 4.5%on April 29, 2024 at 8:14 pm

The increased usage of carboxymethyl cellulose across several industries,pharmaceutical, paints,textiles, showed strong growth in its demand.

- Top 8 Best Edible Massage Oils in 2024on April 26, 2024 at 5:00 pm

Edible massage oils can be a delightful, sensual enhancement to any intimate experience. These specially formulated oils are designed to be massaged into the skin, creating a smooth, silky feeling ...

- Can You Eat Cicadas? Can Your Dog Do So?on April 26, 2024 at 4:00 am

This spring two broods of periodical cicadas will pour out of the ground for a weeks-long stint of mating and egg laying across swaths of the eastern half of the U.S. The bugs are large and loud—but ...

- Edible-Packaging Market Exclusive Report on the Latest Revenue and Future Scopeon April 24, 2024 at 2:17 pm

The Global Edible-Packaging Market Size is valued at 608.84 million in 2023 and is predicted to reach 1054.60 million by the year 2031 at an 7.30% CAGR during the forecast period ...

- Edible-Packaging Market Exclusive Report on the Latest Revenue and Future Scopeon April 23, 2024 at 5:00 pm

Nanotechnology is a vital instrument for extending the shelf life of food goods. Natural polymers are widely used in developing edible coatings because they are affordable, easily obtainable, and ...

- Wax coating to protect produce from bacteria, fungion April 23, 2024 at 3:07 am

The wax coating technology is expected to bolster the safety of fresh produce and offer enhanced protection against bacteria and fungi, as well as providing both immediate and delayed antibacterial ...

- Saveggy Raises €1.76M for Edible Fruit & Veg Coating as Solution to Plastic Packagingon April 19, 2024 at 7:51 am

Swedish startup Saveggy has raised €1.76 million (SEK 20M) for its plant-based alternative to plastic packaging designed to preserve the shelf life of ...

- Investors back Swedish Saveggy’s mission to reduce food waste with innovative edible coatingon April 19, 2024 at 2:31 am

Saveggy, a Lund-based foodtech startup, has raised €1.76 million in funding from investors like Unconventional Ventures, LRF Ventures, Almi Invest GreenTech, ...

- How to grow and pick edible flowerson April 17, 2024 at 5:00 pm

Though flowers have been used in cooking since ancient times, the so-called foodie movement has made the use of edible flowers even more visible in recent years. The blossoms are easily tossed ...

- Why Edible Garden Stock Is Racing Higheron April 17, 2024 at 5:25 am

Edible Garden reports a preliminary Q1 year-over-year increase in produce revenues of 40% and an increase in cut herb revenue of 200%. The company attributes the growth to its investments in ...

The Latest Google Headlines on:

Edible coatings

[google_news title=”” keyword=”Edible coatings” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Edible films

- Pop-Tarts Celebrates 'Unfrosted' Film With Jerry Seinfeld And Limited-Edition Boxeson April 30, 2024 at 5:39 am

Pop-Tarts was not involved in the making of the upcoming Netflix film Unfrosted, a fictional comedy about the origins of the beloved toaster pastry, but the brand is celebrating the release with ...

- How Fiction Became Edibleon April 30, 2024 at 4:00 am

A new genre of cookbooks is reverse engineering the foods of all your favorite pop culture. Now, your stomach can travel to Westeros, Tattoine, the Shire, and more.

- NOT BROUGHT TO YOU BY POP-TARTS®: POP-TARTS REACTS TO JERRY SEINFELD'S 'UNFROSTED' FILM, STREAMING ON NETFLIX MAY 3on April 29, 2024 at 6:00 am

Tarts®, especially when the movie is about the Crazy Good snack itself. Pop-Tarts are the subject of Jerry Seinfeld's highly anticipated Netflix film, UNFROSTED, a fictional comedy about the Pop-Tarts ...

- The ethics of eating monsterson April 28, 2024 at 9:10 am

Unfortunately, Star Wars never really interrogates the ethics of eating. Then again, it isn’t often that the ethics of eating are ever considered in fiction, which is why "Delicious in Dungeon" is ...

- Top 8 Best Edible Massage Oils in 2024on April 26, 2024 at 5:00 pm

Edible massage oils can be a delightful, sensual enhancement to any intimate experience. These specially formulated oils are designed to be massaged into the skin, creating a smooth, silky feeling ...

- Edible-Packaging Market Exclusive Report on the Latest Revenue and Future Scopeon April 23, 2024 at 5:00 pm

Furthermore, the Food and Drug Administration’s stringent regulations are thought to harm the market, which demands that edible films be approved as safe, hygienic, and healthy. Additionally, ...

- Seth MacFarlane Shares ‘Family Guy’ Movie Plans, Reveals Hulu Will Air 2 Original Episodeson April 20, 2024 at 6:27 pm

At PaleyFest, the "Family Guy" cast also did a live read of an upcoming episode befitting 4/20, "Edible Arrangement." ...

- Edible Book Festival at NMSU encourages creativityon April 19, 2024 at 7:27 pm

The Edible Book Festival is an international event where people create dishes inspired by books. The event is usually celebrated on April 1, but NMSU has always hosted this event with the College of ...

- These Are the 8 Best Fruit and Veggie Skins to Eaton April 19, 2024 at 11:22 am

Eating certain fruit and vegetable skins may provide additional nutrients that support your health. Here are the best ones to eat—and a few unsafe ones to avoid.

- 'Sasquatch Sunset' showcases bigfoot like audiences have never seen beforeon April 18, 2024 at 7:30 pm

The R-rated, no-holds-barred film stars Jesse Eisenberg and Riley Keough as members of a Sasquatch pack. #k5evening ...

The Latest Google Headlines on:

Edible films

[google_news title=”” keyword=”edible films” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]