Lab-on-a-chip devices work by directing small samples of liquid through tiny “microchannels” embedded in a small platform, and are used for analyzing liquids in medical and scientific settings.

Earlier this week, we reported on a high school teacher who has invented a way of creating such devices using transparency film and a photocopier. Now, scientists from Indiana’s Purdue University have announced a new method of making them using paper. While previous approaches have involved laying down lines of wax or other hydrophobic (water-repelling) material on hydrophilic (water-absorbing) paper, this method uses store-bought hydrophobic paper, and creates the microchannels by burning away the waterproof coating with a laser.

Currently, lab-on-a-chip devices are made by using photolithography or etching techniques to create microchannels on small glass or plastic platforms. The liquid being analyzed must then be pumped through those channels using tiny pumps and valves.

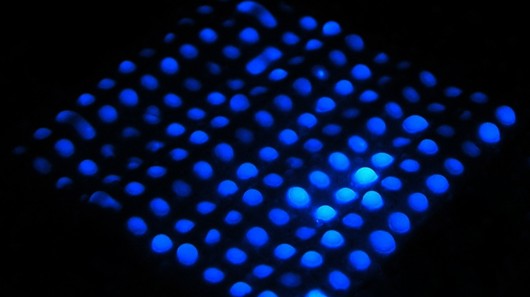

The Purdue process starts with a strip of ordinary wax or parchment paper, such as that used for cooking. Once the laser burns away the wax in precise lines, dots and patterns, the underlying base hydrophilic paper is exposed. Silica microparticles are also placed in key locations, to help draw the liquid through the channels. As with conventional paper strip tests, the liquid is ultimately drawn to a reagent, which will cause the paper to change color if a specific chemical is present in the liquid. Utilizing the microchannels, different parts of the paper strip could be used to test for different chemicals within the same sample.