A larger version of this high-speed sintering machine is now in the works.

An emerging additive manufacturing technology could be fast and cheap enough to compete with conventional methods, but it faces materials-related challenges

The inventor of a new kind of 3-D printer says his research group will build a massive machine capable of mass-producing competitively priced plastic parts within two years.

Making plastic parts layer by layer according to digital instructions is a very slow process compared with conventional methods. That’s why additive manufacturing–or 3-D printing, as it is more popularly known–has thus far been economical only for making small batches of niche products like dental implants and hearing-aid shells. The new technique could increase the number of parts that can be made economically this way from thousands to millions at a time, at least for small, complicated objects.

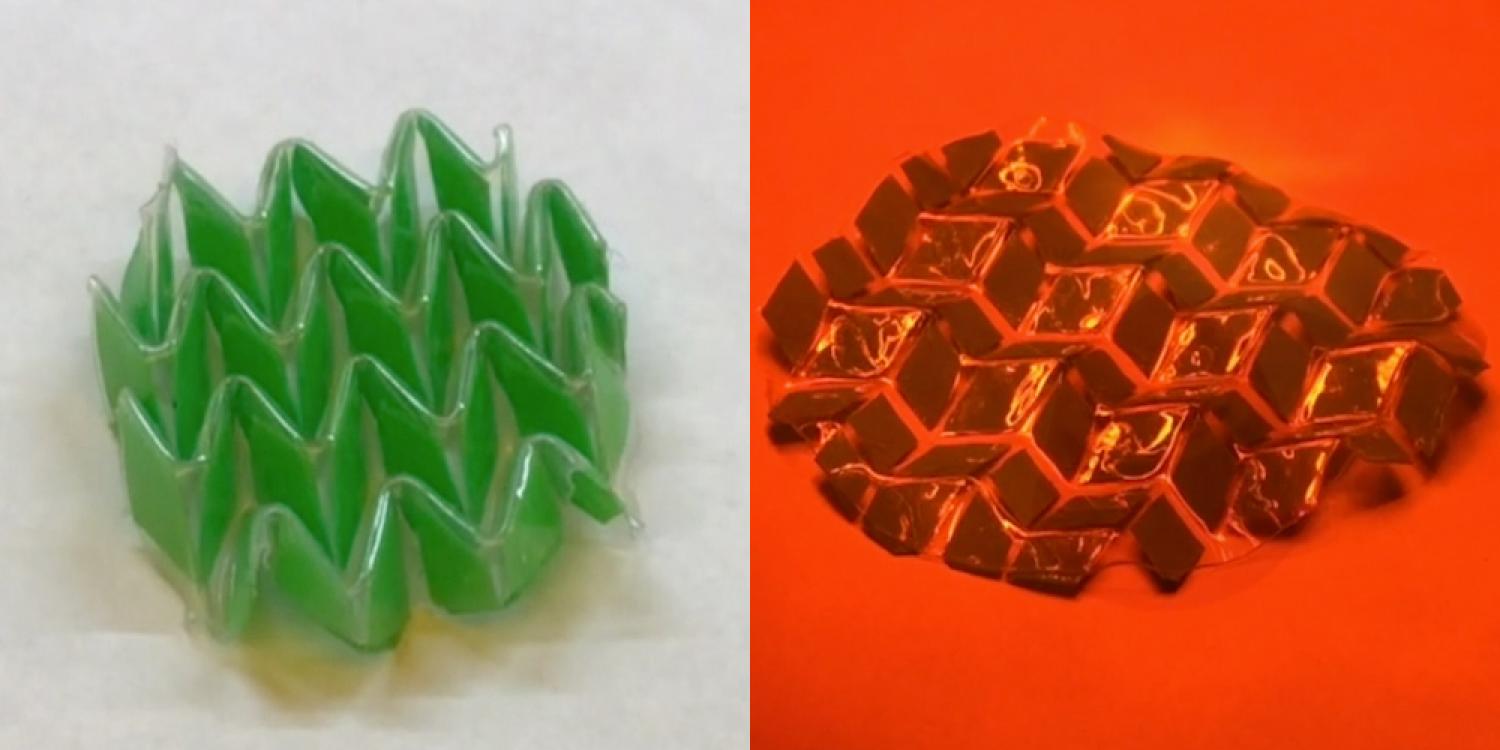

Compared with conventional technologies like injection molding, additive manufacturing could significantly reduce material use and eliminate the costly machine tooling needed to make certain complicated shapes. It also makes it more practical to design unique architectures for parts that, for example, could help make automobiles and aircraft lighter and more fuel-efficient (See “10 Breakthrough Technologies 2013: Additive Manufacturing”).

Neil Hopkinson, a professor of mechanical engineering at the University of Sheffield in the United Kingdom, has been developing the new method, called high-speed sintering, for over a decade.

Laser sintering machines build objects by using a single-point laser to melt and fuse thin layers of powdered polymer, one by one. Hopkinson replaced the laser system, which is both expensive and slow, with an infrared lamp and an ink-jet print head. The print head rapidly and precisely delivers patterns of radiation-absorbing material to the powder bed. Subsequently exposing the powder to infrared light melts and fuses the powder into patterns, and the machine creates thin layers, one by one—similar to the way laser sintering works, but much faster.

Hopkinson’s group has already shown that the method works at a relatively small scale. They’ve also calculated that, given a large enough building area, high-speed sintering is “on the order of 100 times faster” than laser sintering certain kinds of parts, and that it can be cost competitive with injection molding for making millions of small, complex parts at a time, says Hopkinson. Now the group will actually build the machine, using funding from the British government and a few industrial partners.

High-speed sintering has the potential to be “very quick,” and the process could end up being much cheaper than laser sintering in certain cases, says Phil Reeves, the vice president of strategic consulting for Stratasys, a leading maker of many kinds of additive manufacturing machines and materials. However, a lot of work is still needed to develop materials that can work with the process, he says. Judging from what Hopkinson has made public, the range of plastics that work with high-speed sintering is quite limited, Reeves says, and many widely used plastics may not be compatible with the process, since it relies on combining the powder with an additional, light-absorbing material.

Read more: Could This Machine Push 3-D Printing into the Manufacturing Big Leagues?

The Latest on: 3D Manufacturing

[google_news title=”” keyword=”Mengla virus” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: 3D Manufacturing

- Deadly Powassan tick virus confirmed in Sharon, Massachusettson April 26, 2024 at 2:07 pm

TICKS FOR THE FIRST TIME. A CONFIRMED CASE OF POWASSAN VIRUS IN SHARON. EXPERTS SAY THE TICK BORNE DISEASE IS MUCH RARER THAN LYME, BUT IT CAN BE DANGEROUS AND EVEN DEADLY. THE PEOPLE THAT I’VE ...

- Fragments of Bird Flu Virus Found in 1 in 5 Milk Sampleson April 26, 2024 at 1:03 am

Fragments of Bird Flu Virus Found in 1 in 5 Milk Samples By Robin Foster HealthDay Reporter FRIDAY, April 26, 2024 (HealthDay News) -- Bits of bird flu virus have been discovered in roughly 20% of ...

- Traces of bird flu are showing up in cow milk. Here’s what to knowon April 25, 2024 at 10:09 am

News that bird flu has been spreading between cows for months and that fragments of the virus are even showing up in milk on U.S. grocery store shelves have fueled new worries about the risk the ...

- Remnants of bird flu virus found in pasteurized milk, FDA sayson April 24, 2024 at 12:31 pm

The U.S. Food and Drug Administration said Tuesday that samples of pasteurized milk had tested positive for remnants of the bird flu virus that has infected dairy cows. The agency stressed that ...

- Traces of bird flu virus have been found in milk. What's going on? Is dairy safe?on April 24, 2024 at 9:34 am

Fragments of the virus that causes bird flu have been found in samples of pasteurized milk, the Food and Drug Administration said Tuesday, but officials aren't concerned about danger to humans ...

- Remnants of bird flu virus found in pasteurized milk: FDAon April 24, 2024 at 8:08 am

The US Food and Drug Administration said Tuesday that samples of pasteurized milk had tested positive for remnants of the bird flu virus that has infected dairy cows. The agency stressed that the ...

- Christina Applegate Says She Wore Diapers After Contracting Virus from Tainted Saladon April 23, 2024 at 8:54 pm

John Shearer/Getty Christina Applegate is getting candid about how she ended up needing to wear diapers after contracting a virus from a tainted salad. Applegate, 52, recalled the health ...

- Fragments of Bird Flu Virus Discovered in Milkon April 22, 2024 at 4:59 pm

Over the last month, a bird flu virus known as H5N1 has been detected in more than 30 dairy herds in eight states. The virus is also known to have infected one farmworker, whose only symptom was ...

- Cats with immuno virus: They can live normal lives; they can't infect dogs or peopleon April 21, 2024 at 5:00 pm

Feline Immunodeficiency Virus is very similar to the HIV in humans. The fact is, however, that FIV-positive cats can live long, happy and healthy lives with few or no symptoms. With so many cats ...

- Bird flu virus now found in milk, is of “great concern” to WHOon April 19, 2024 at 9:31 am

The organization also announced Friday that the virus has been found in raw milk. Dr. Jeremy Farrar, chief scientist at the WHO, noted that the avian flu, also called H5N1, had an “extremely ...

via Bing News