There is a large growth market for flexible circuits, RFID antennas and biosensors on films.

Researchers from the Fraunhofer Institute for Surface Engineering and Thin Films IST are presenting a new technology at K 2010, the international trade fair for plastics and rubber (Hall 3, E91): the experts can now apply conductive metal circuits to plastic substrates in a process that is energy- and material-conserving and thus more sustainable.

Flexible circuits can be found in many devices where space and weight considerations are dominant in the design of electronics: in cars, in cameras and video equipment, in mini-computers for athletes or in inkjet printers. And the market continues to grow: according to the business consultancy Frost & Sullivan, sales in this area will grow to more than $16 billion by the year 2014.

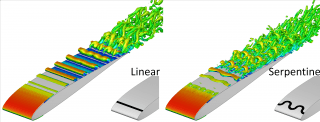

At K 2010, the trade fair for plastics in Düsseldorf, Germany, scientists from the IST in Braunschweig will unveil a new reel-to-reel technology for the production of flexible circuits and biosensors; the new technology is known as “P3T,” which is shorthand for “Plasma Printing and Packaging Technology.” The benefits: P3T involves considerably fewer process steps than existing processes, and it conserves raw materials. Unlike previous methods, the researchers do not start with a polymer film metalized over its entire surface from which excess metal is then removed to create the circuits. Instead, to produce flexible circuit boards, they apply circuits made of copper to the film that serves as substrate. In the case of biosensors, palladium is used. They use plasma at atmospheric pressure and galvanization instead of vacuum-pressure and laser-based methods to achieve inexpensive and resource-efficient production.

Dr. Michael Thomas, director of the research group at IST, explains: “During production of circuits for an RFID antenna, you often have to etch away between 50 and 80 percent of the copper used. This results in considerable amounts of copper scrap that either has to be disposed or reprocessed using relatively elaborate methods.” The IST approach is different: there, scientists use the additive process to apply the structures they want directly to the substrate sheeting.