Technique paves the way for more complex soft devices

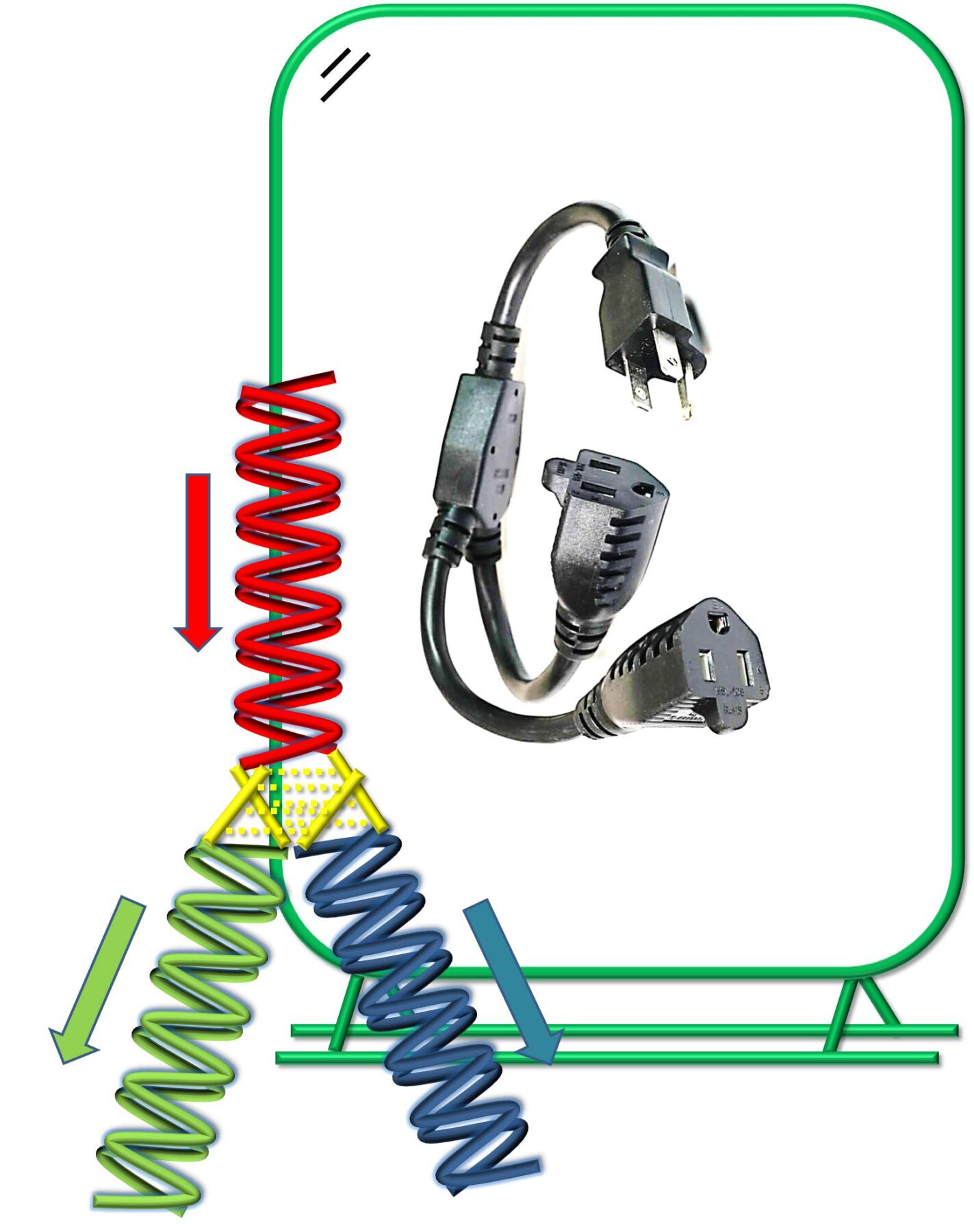

Every complex human tool, from the first spear to latest smartphone, has contained multiple materials wedged, tied, screwed, glued or soldered together. But the next generation of tools, from autonomous squishy robots to flexible wearables, will be soft. Combining multiple soft materials into a complex machine requires an entirely new toolbox — after all, there’s no such thing as a soft screw.

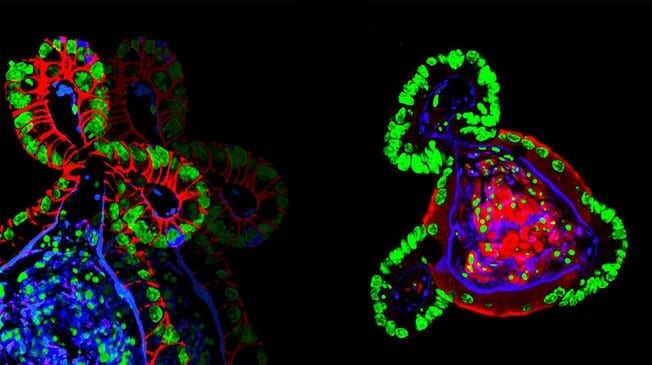

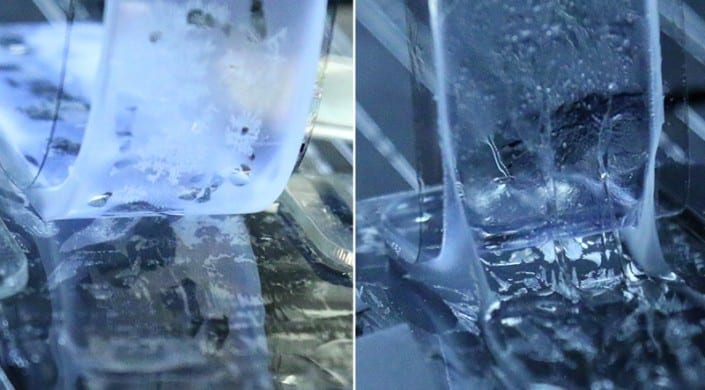

Current methods to combine soft materials are limited, relying on glues or surface treatments that can restrict the manufacturing process. For example, it doesn’t make much sense to apply glue or perform surface treatment before each drop of ink falls off during a 3D printing session. But now, researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have developed a new method to chemically bond multiple soft materials independent of the manufacturing process. In principle, the method can be applied in any manufacturing processes, including but 3D printing and coating. This technique opens the door to manufacturing more complex soft machines.

“This technique allows us to bond various hydrogels and elastomers in various manufacturing processes without sacrificing the properties of the materials,” said Qihan Liu, a postdoctoral fellow at SEAS and co-first author of the paper. “We hope that this will pave the way for rapid-prototyping and mass-producing biomimetic soft devices for healthcare, fashion and augmented reality.”

The researchers also demonstrated that hydrogels — which as the name implies are mostly water — can be made heat resistant in high temperatures using a bonded coating, extending the temperature range that hydrogel-based device can be used. For example, a hydrogel-based wearable device can now be ironed without boiling.

The Latest on: Complex soft machines

[google_news title=”” keyword=”Complex soft machines” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Complex soft machines

- The 2024 PureWow Readers' Favorite Awardson April 30, 2024 at 10:01 am

PureWow Editors select every item that appears on this page,, and the company may earn compensation through affiliate links within the story You can learn more about that process here. Yahoo Inc. may ...

- Fading lights: Multiple threats to North America's firefly populationson April 30, 2024 at 8:36 am

Scientists have applied a data-driven approach to understanding firefly population dynamics on a continental scale. Key findings from this new study indicate that fireflies, part of the beetle order, ...

- Rice students develop low-cost cold spray metal Additive Manufacturing machine prototypeon April 30, 2024 at 7:18 am

Students from Rice University have developed a CSAM device that relies on pressure and velocity, rather than temperature, for metal part.

- Doherty: Stern warning about NFL use of Guardian Capson April 30, 2024 at 6:00 am

For the first time, voluntary use of the Guardian Cap devices will be allowed during games in the 2024-25 season.

- Researchers develop method to move objects around with a jet of windon April 30, 2024 at 5:32 am

Scientists have developed a new method to move objects without any direct contact. The new approach uses a jet of wind to move objects. The method manipulates objects at a distance and could be ...

- Protesters take over Columbia's Hamilton Hall; Taylor Swift back at No. 1; Travis Kelce signs new deal | Hot off the Wire podcaston April 29, 2024 at 7:35 am

NEW YORK (AP) — Columbia University in New York has limited campus access to students and essential employees after dozens of protesters took over a building. They barricaded the entrances and ...

- 50 Movies That Are Basically Perfecton April 27, 2024 at 5:00 am

Most movies have something wrong with them. There are movies, though, with nothing worth complaining about; movies whose flaws (if they can be said to have any) fold so well into the total package as ...

- 17 Best Coffee Makers of 2024 to Get You Through the Dayon April 26, 2024 at 4:44 pm

Coffee lovers rejoice! Whether your days are powered by caffeine or you’re a decaf type, you’ll appreciate having one of the best coffee makers in your kitchen. And fortunately, there are plenty of ...

- How the pretzel went from soft to hard – and other little-known facts about one of the world’s favorite snackson April 26, 2024 at 6:11 am

The pretzel, one of the fastest-growing snack foods in the world, recently crossed a billion dollars a year in sales. It has its own emoji, comes in flavors like pumpkin spice, mocha and banana, and ...

- 30 Movies That Have Definitely Not Aged Wellon April 26, 2024 at 5:03 am

Not all movies age well with time, especially these. Here is an incomplete list of movies that have become increasingly cringe-worthy over the years.

via Bing News