A team at the University of Louisville has taken bioprinting a step farther by creating a working 3D printed human heart made of fat cells

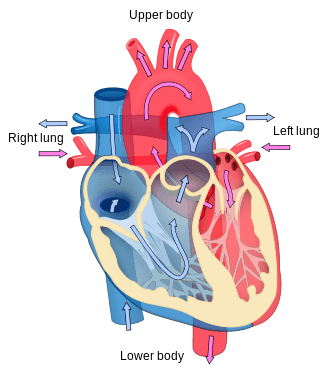

Imagine your beating, pumping heart, working hard right this moment to keep you alive. Now think of a future where, if your heart failed or has a defect, you could get one that works better and lasts longer.

It sounds like something out of a sci-fi movie, but researchers at the University of Louisville have moved a step closer in this direction by using a 3D printer to make working parts of a human heart, using fat cells and collagen.

“We are utilizing printing and other biological manufacturing techniques to build these different parts of the heart,” Dr. Stuart Williams told TechRepublic. Williams is the chief of the Bioficial Heart program at the University of Louisville’s Cardiovascular Innovation Institute in Louisville, Kentucky.

He added that the team has not reached the point where they put together the valves and the blood vessels, or any other products. They are solely focused on creating working pieces of the muscle.

Williams described the process as similar to building an airplane. Airplanes aren’t built in the traditional 3D printing sense, where you would start with the wheels at the bottom and build up. The parts for an airplane are made piece by piece, then assembled together.

Same with a human heart, which is a complex muscle. It can’t be built at once, so each part — the valves, large blood vessels, small blood vessels, electrical conducting system — is built and assembled together with a giant, intricate 3D printer.

To print the heart, Williams and his team use collagen and fat cells. One liter of fat from someone can give them a huge number of cells that can be directly translated to patients, he said.

“[We are] taking a piece of fat, isolating regenerative cells in the fat, utilizing those, then mixing factorized cells with collagen, and it prints.”

What’s even more innovative is the “six-axis” printer Williams helped build that makes the heart one section at a time. This “robot” can build the specific parts, then move them around and place them in their correct positions within the muscle.

The U of L lab is the only one in the world that has this intricate of a 3D printer, made specifically for bioprinting. Williams calls it a “bioassembly tool.”

The Latest on: Bioprinting

[google_news title=”” keyword=”Bioprinting” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Bioprinting

- New technique bioprints live cells inside the body using ultrasonic waveson May 8, 2024 at 10:36 pm

Revolutionary acousto-printing method can be used to circumvent invasive surgery, and has a wide array of potential applications.

- 3D Bioprinting Market Expected to Hit USD 6.9 Billion by 2032 | Market.Uson April 11, 2024 at 11:10 pm

According to a recent report by Market.us, the Global 3D Bioprinting Market size is expected to be worth around USD 6.9 Billion by 2032 from USD 1.9 Billion in 2023, growing at a CAGR of 16.1% during ...

- 3D printing and bioprinting in healthcare - statistics and factson April 10, 2024 at 5:00 pm

Bioprinting is a much newer technology compared to 3D printing and uses bioinks and other biomaterials to create organ-like structures. Some have referred to bioprinting as ‘healthcare’s next ...

- Advancing gastric cancer treatment through personalized 3D bioprintingon March 21, 2024 at 10:37 am

By using 3D bioprinting to accurately replicate the biological environment surrounding gastric cancer cells, the researchers have achieved a significant feat—predicting a patient's response to ...

- Bioprinting News and Researchon March 17, 2024 at 5:00 pm

FluidForm Bio, a leader in developing life-like human tissue to treat disease, shares recent advancements in building human cardiac tissues using FRESH™ 3D bioprinting. FluidForm Bio ...

- TissueFab® bioink Conductive for 3D bioprintingon November 22, 2023 at 11:00 pm

TissueFab ® bioink Conductive Vis/405 nm, low endotoxin, is a bioink tailored for 3D bioprinting with electrical conductivity. This specialized bioink is designed to create optimal conditions for ...

- Revolutionising osteoarthritis treatment through bioprintingon September 25, 2023 at 7:40 am

In collaboration with clinicians and cell biologists and using the unique capability of The University of Manchester’s Bioprinting Platform, Dr Marco Domingos is developing new technology-driven ...

- 26 Million New Cases, Three Dimensions, And One New Technology: How Bioprinting Can Improve Cancer Treatmentson July 11, 2023 at 3:30 pm

printed from a model (such as the gold bracelet model seen on the laptop screen). Bioprinting, also known as 3D bioprinting, uses cells, growth factors (naturally occurring substances that help ...

- Will 'Bioprinting' Body Parts Lead To Crazy Cosmetic Requests?on July 19, 2022 at 5:00 pm

Please confirm that you would like to log out of Medscape. If you log out, you will be required to enter your username and password the next time you visit. Log out ...

- How bioprinting workson May 8, 2011 at 5:00 pm

The first bioprinters were jury-rigged desktop inkjet printers. Now, some labs use machines, made specifically for bioprinting, that cost up to $300,000. Cornell labs make multipurpose 3-D ...

via Bing News