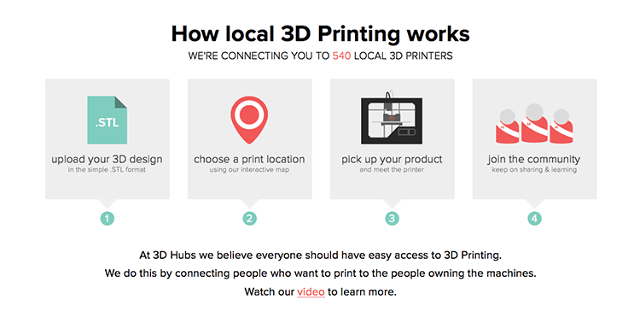

The crystallized oxide (lighter regions) spelling the word “small” was “printed” on a non-crystallized layer (darker gray) by a well-controlled beam in an electron microscope. The area shown is only 160 by 80 nanometers (about a thousandth of the diameter of a human hair). The green background is an enlarged high resolution image of the letter “s”, showing its crystalline, ordered atomic structure.

A new tool allows atomic 3D printing

The Science

A new tool now rests in the 3D printing toolbox. The electron beam in a scanning transmission electron microscope has been exquisitely controlled with specially programmed electronics to tunnel into non-crystalline material and construct 3D features that are in perfect alignment with the underlying substrate (i.e., epitaxial). The result is designer materials with desirable structures, such as microchips, or materials with unique properties. Essentially, any shape can be created by exposing patterned areas to higher numbers of electrons than non-patterned areas, resulting in epitaxial 3D features down to 1-2 nanometers — less that the width of a strand of DNA.

The Impact

Electron microscopes with atomically focused beams, even from older instruments, can easily be transformed from characterization tools to nanoscale fabrication platforms, complementing macroscopic 3D printing. This nanoscale fabrication tool could be used to make integrated circuits and non-equilibrium systems such as strategically concentrated impurities in crystals that lead to unique properties.

Summary

3D printing has revolutionized the way we can make and design materials. Now a team led by scientists at Oak Ridge National Laboratory has added another tool to the 3D printing toolbox. Combining the focused electron beam in a scanning transmission electron microscope with new electronic controls allowed the atomic sculpting of crystalline material from non-crystalline material and the construction of 3D feature sizes down to 1-2 nanometers. The crystalline features have a particular alignment with the underlying atoms, allowing mechanical and electrical properties to extend throughout the material.

The electron beam from the scanning transmission electron microscope sculpted with atomic precision a crystalline oxide feature from a non-crystalline oxide layer on a crystalline substrate. Interestingly, this non-crystalline oxide layer was made by a usually undesirable process: While preparing a sample for the electron microscope, significant redeposition of the initially crystalline substrate occurs. This redeposited material is non-crystalline and is on top of the initial crystalline film. The electron beam can then sculpt and crystallize this non-crystalline material. Also, in order to achieve this atomic manipulation, scientists had to custom program external electronics to control the trajectory of the electron beam. Electrons hitting the non-crystalline material induce growth of crystalline nanostructures.

The number of electrons hitting the sample controlled the growth rate of the 3D feature from the non-crystalline material. At lower electron beam intensities, the material can be imaged without inducing growth. Nanofabrication with atomic-level sculpting can lead to new 3D materials for integrated circuits as well as new fundamental experimental studies ranging from crystallization to diffusion that can complement modeling and simulation.

Learn more: Atomic Sculpting with a Microscope

The Latest on: 3D nanoprinting

[google_news title=”” keyword=”3D nanoprinting” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: 3D nanoprinting

- Best 3D Printer for 2024on April 23, 2024 at 1:26 am

We've tested and reviewed several models to find the top 3D printers, including options from Prusa, Anycubic, Elegoo, Bambu Lab and more. James has been writing about technology for years but has ...

- Optical Cavities: Harnessing Light at the Nanoscaleon April 18, 2024 at 7:44 am

The development of novel materials and fabrication techniques, such as 3D nanoprinting and atomic layer deposition, may enable the realization of advanced optical cavities with unprecedented ...

- Best 3D modeling software of 2024on April 16, 2024 at 6:06 am

If you're all about bringing ideas to life, the best 3D modeling software is essential. Widely used across the automotive industry, film-making, engineering, gaming, product design, and for 3D ...

- 3D Printing: The Latest Architecture and Newson April 14, 2024 at 5:00 pm

As an additive manufacturing method, 3D printing has been characterized by the construction of objects through the horizontal deposition of material, layer by layer. This still restricts ...

- Elusive 3D Printed Nanoparticles Could Lead to New Shapeshifting Materialson March 25, 2024 at 10:55 pm

“We’ve used a 3D nanoprinting technique to produce one of the most promising shapes known – Archimedean truncated tetrahedrons. They are micron-scale tetrahedrons with the tips lopped off.

- 3D Printingon January 25, 2024 at 4:00 pm

3D printing, or additive manufacturing, has advanced rapidly to enable the production of everything from tiny screws to engine components to entire houses ... and it's only just getting started.

- 3D Printing Meets The Billion-Dollar Footwear Industryon July 18, 2023 at 11:26 pm

Opinions expressed by Forbes Contributors are their own. I'm a journalist covering professional and industrial 3D printing. Shoemakers have been flirting with 3D printing for years. The biggest ...

- Why 3D printed food is set to go mainstreamon May 3, 2023 at 3:36 am

But such technology is no longer the stuff of futuristic fiction – it’s here now in the form of 3D food printers. It was back in the ’80s when experimentation began with 3D printing.

- 3D-Printed Rockets Set To Blast Offon June 30, 2022 at 9:31 am

Opinions expressed by Forbes Contributors are their own. I'm a journalist covering professional and industrial 3D printing. Relativity Space stage 1 3D-printed rocket being installed at Cape ...

- Watch: Recognising 3D shapeson July 25, 2020 at 9:11 pm

Faces - A face is a flat surface on a 3D shape. For example a cube has 6 faces. Edges - An edge is where two faces meet. For example a cube has 12 edges. Vertices - A vertex is a corner where ...

via Bing News