Technology developed by UNSW Canberra researchers could provide an environmentally friendly, cost-effective method of sterilising water.

On 22 March, World Water Day, the United Nations will shine a light on the availability of clean water. Today, 2.1 billion people live without safe water at home and one in four primary schools have no drinking water service.

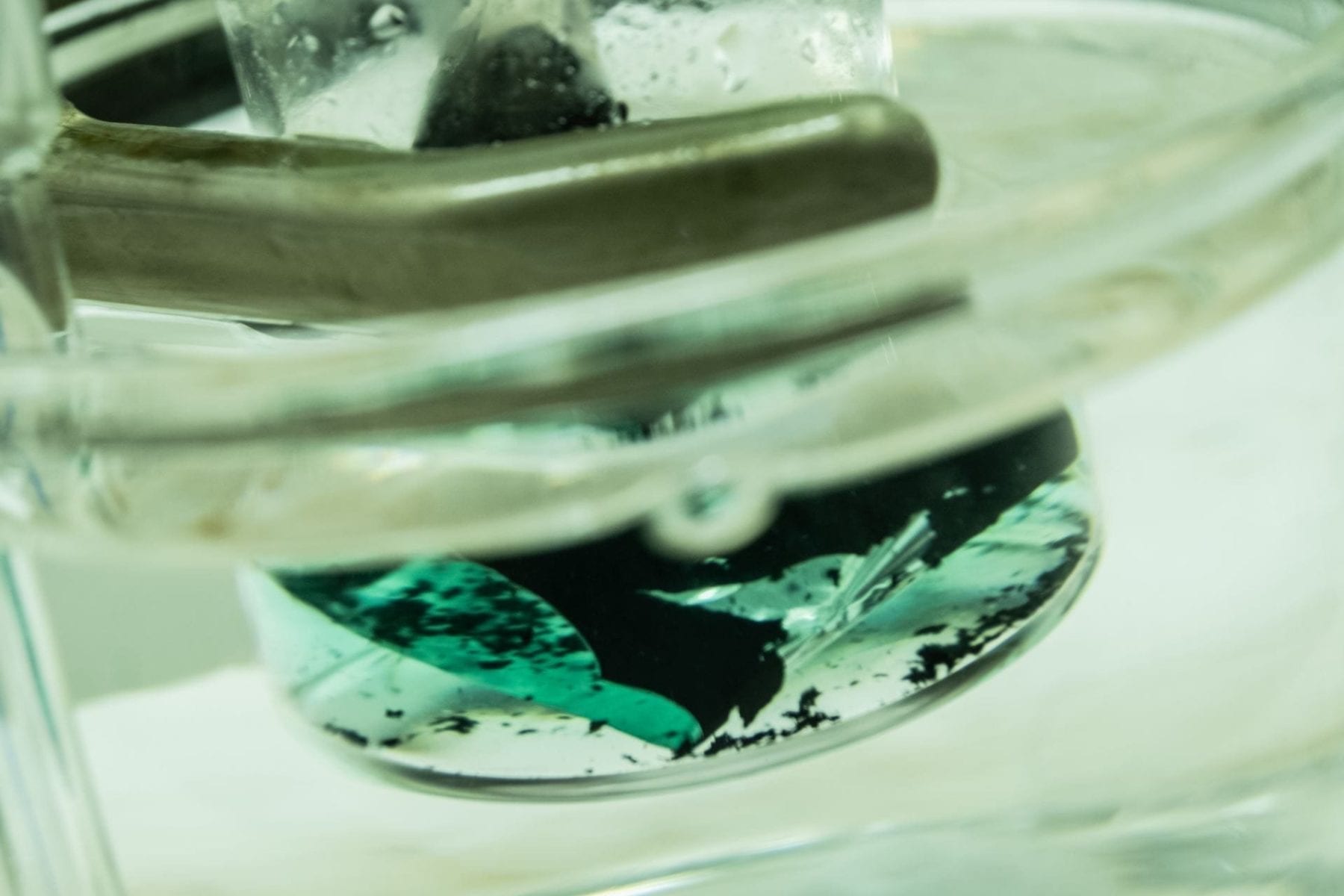

Developed by UNSW Canberra researchers, Dr Adrian Garrido Sanchis, Professor Richard Pashley and Australian National University Emeritus Professor Barry Ninham, the technology bubbles un-pressurised carbon dioxide (CO2) through wastewater in a bubble column, effectively inactivating both bacteria and viruses.

This new technology is capable of sterilising water with hot CO2, which considerably reduces the energy requirements when compared with boiling water, as heating gas is much more efficient than heating water.

It is also safer than chemical treatments, such as chlorine.

Dr Sanchis first tried to inactivate viruses with a bubble column while he was completing his PhD at UNSW Canberra.

“The collision between the hot air bubbles and the viruses was the mechanism behind the inactivation,” he said.

“Then I tried to improve the inactivation effect with different solutions, with air at different temperatures and finally with different hot gases. This proved that hot carbon dioxide inactivated virus and bacteria faster than the other gases. Therefore, we decided to conduct a specific CO2 pathogen inactivation study.”

Dr Sanchis said current water disinfection technologies have several limitations.

“This new technology could become a new sterilisation technology candidate able to compete with the existing ones,” he said. “The fact that the process can use heated CO2 gas instead of heated water and the possibility of reusing exhaust gas from combustion processes makes the new process potentially more energy efficient.”

Australian Pork Limited (APL) has previously funded research into this new technology and is interested in supporting the next phase of the research towards commercialisation.

“APL funded the construction of a small pilot plant for pure water production from the condensation of the saturated gases from the bubble column,” Dr Sanchis said.

“This pilot plant was able to produce pure condensed water and also sterilise the piggery effluent, producing another output of sterilised water.

“Many waste disposal industries, like landfills, piggeries, waste-water treatment plants, bio-gas plants and coal power plants emit large amounts of CO2. There is the potential for them to use these emissions in water treatment processes to sterilise water.”

The United Nation’s 2030 Agenda for Sustainable Development includes a target to ensure available and sustainable management of water for all by 2030. New technology, including this water sterilisation method, could contribute to achieving that goal.

Learn more: UNSW Canberra researchers develop new water sterilisation method

The Latest on: Sterilizing water

[google_news title=”” keyword=”sterilizing water” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Sterilizing water

- 5 essential gadgets for turning your home into a self-care sanctuaryon May 2, 2024 at 2:58 am

While some people gain energy from going out and talking to people, others gain it from staying at home. Spending a cosy night in can be a comforting and restorative experience, whether you're curling ...

- Gardens of Good and Evilon May 2, 2024 at 2:00 am

These spaces have historically been tied to exclusion and injustice, but we can cultivate them to be ethical and environmentally beneficial.

- Video Questions Clorox Wipes' Safety on 'Food Surfaces' for High Chairs, Countertops and Tables. Here's What Clorox Sayson May 1, 2024 at 3:51 pm

In late April 2024, U.S. TikTok user Chelsie Gilbert (@chelsiegilbert1) posted a video she recorded in a Target store. In the clip, she made several claims about the purported dangers of Clorox ...

- Are Clorox Wipes Not Safe for Use on 'Food Surfaces' for High Chairs, Countertops and Tables?on May 1, 2024 at 3:51 pm

A video went viral in April 2024 showing a mother talking about the purported dangers of cleaning "food surfaces" with Clorox disinfecting wipes.

- New EPA rule says over 200 US chemical plants must reduce toxic emissions linked to canceron May 1, 2024 at 2:59 pm

Ethylene oxide is used as a sterilizing agent for medical equipment ... 70 million Americans drink water from systems reporting PFAS to EPA. Patrice Simms, vice president of the environmental law firm ...

- This experimental indie is exactly the kind of avant-garde original story telling gaming needs right nowon May 1, 2024 at 11:00 am

Odd Meter, the developers behind Indika, have found a way to make this seemingly simple story work with the power of environmental puzzles, dark humor, and light psychological horror. Oh, and just a ...

- Toxic gas adds to a long history of pollution in southwest Memphison May 1, 2024 at 9:00 am

The air in this part of the city has long been considered dangerous. An oil refinery spews a steady plume of white smoke. A coal plant has leaked ash into the ground and the groundwater.

- Livingston Parish Government working to find cause of Killian water system failureon May 1, 2024 at 8:14 am

The Livingston Parish Government is updating Killian residents on the ongoing water system failure in Killian.

- Best Deals Under $100on April 29, 2024 at 9:47 am

Shop great discounts on kitchen products, tech gadgets, and moreWe’re highlighting deals on products that score well in Consumer Reports’ tests and cost less than $100. You don’t have to ...

- I'm an American who gave birth to my 3 kids in Germany. I had a postpartum midwife covered by insurance, and a water birth in the hospital.on April 26, 2024 at 3:32 am

I moved to Germany over a decade ago and had all my three kids here. My insurance covered everything but I didn't know who was attending my birth.

via Bing News