The idea behind it is over 100 years old

DYSPROSIUM and neodymium are not exactly the best-known elements in the periodic table, but for makers of high-end electric motors they have become vital. Both are strongly magnetic and thus crucial to the construction of powerful motors of the sort used, for example, in electric cars. Unfortunately, they lurk in the part of the table known as the rare-earth metals and, as that name suggests, workable deposits of them are scarce. At the moment, the main source of supply is in China, whose government has used its near-monopoly to restrict availability and push up the price. So there is a lot of interest in inventing motors that can do without them. And several groups of researchers think they have come up with one.

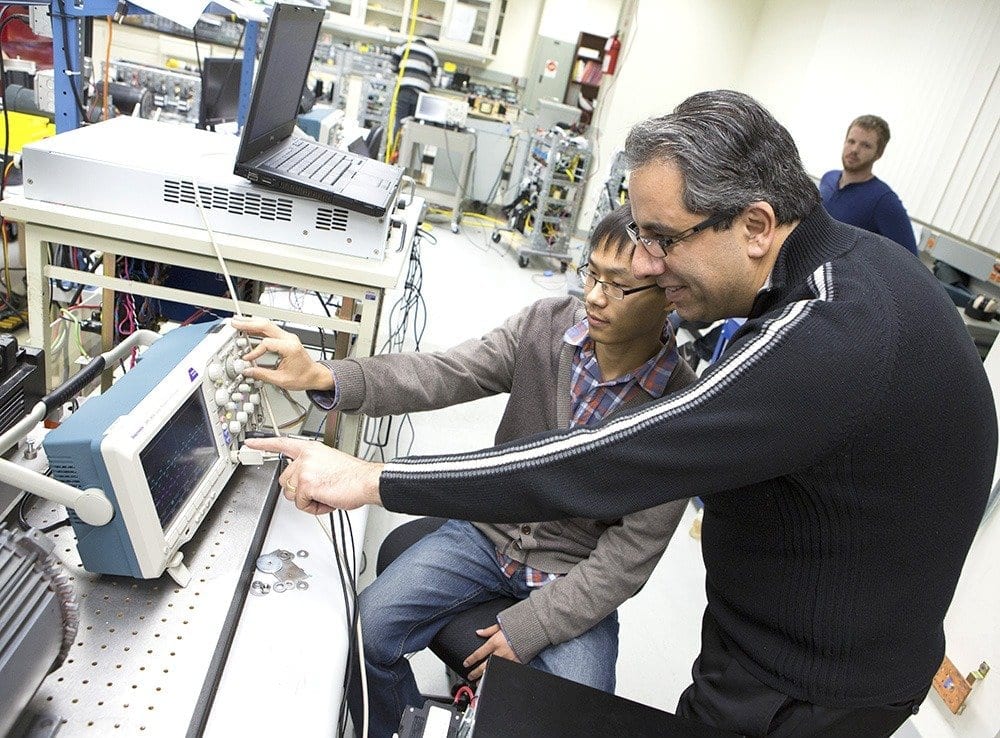

The device in question is known as a switched reluctance motor. The idea behind it is over 100 years old, but making a practical high-performance version suitable for vehicles has not been possible until recently. A combination of new motor designs and the advent of powerful, fast-switching semiconductor chips, which can be used to build more sophisticated versions of the electronic control systems required to operate a reluctance motor, is giving those motors a new spin.

One of the leading contenders is Inverto, a research and development company based in Ghent, Belgium. Inverto’s engineers, led by John De Clercq, the firm’s research director, are collaborating with the University of Ghent and the University of Surrey, in Britain, and also with an unnamed carmaker. They already have a motor running in a car. At Newcastle University, also in Britain, researchers are working with several companies to produce reluctance motors for both cars and lorries. And studies are being carried out in America and Japan too. A team led by Nobukazu Hoshi of the Tokyo University of Science, for example, has experimented with a reluctance motor in a Mazda sports car.

Let’s twist again

The main practical difference between a reluctance motor and a normal one is that the reluctance motor has no permanent magnets. A normal motor (one that runs on direct current, at least) has two parts. One, the rotor, moves. The other, the stator, does not. The stator usually forms the casing and houses a set of permanent magnets. The rotor, which turns inside that casing, is surrounded by copper windings that act as electromagnets. The motor works by the periodic reversal of the current running through these windings. That reverses the polarity of the electromagnets and causes the rotor to be pulled around by attraction and repulsion between the electromagnets and the permanent magnets.

Traditionally, this current reversal was achieved with a rotary switch known as a commutator, which transmitted electricity to the windings through brushes that made contact with conductive strips which passed under them as the rotor turned. Modern motors use electronic control systems rather than a commutator, but the principle is the same.

A switched reluctance motor is like a normal modern motor in this respect—it is also brushless. But unlike a normal motor it has no need of permanent magnets, rare-earth or otherwise, for it works on a different principle: least magnetic reluctance.

Reluctance in magnetism is analogous to resistance in electricity. Just as a current travels along the path of least resistance, so the flux of a magnetic field (the “lines of force”, for those who remember childhood experiments with bar-magnets, sheets of paper and iron filings) takes the path of least reluctance. And iron, a material that is nice and cheap, has very low reluctance.

Inverto’s reluctance motor has a rotor made of iron sheets, while the inside of the stator is covered with copper windings. Current is fed to these windings on the say-so of the control system, generating flux. That flux then follows the path of least reluctance—ie, through the sheet-iron rotor. The rotor attempts to align itself to the flux in a way that reduces reluctance to a minimum, and that causes it to turn.

The control system, however, constantly anticipates the rotor’s movement and switches the current between windings so as to stop the rotor settling into its preferred alignment. As a result, it keeps on turning.

Reluctance motors still have disadvantages, even now that the control problem has been solved. For example, to deliver a given amount of twisting force—or torque—a reluctance motor has to be larger than an equivalent permanent-magnet motor. But the materials needed to build them are significantly cheaper. Moreover, according to Dr De Clercq, the motors’ torque characteristics make them particularly suitable for cars.