Electric power and electronics are playing an ever-increasing role in all kinds of vehicles.

Currently copper is the conductive material of choice. But in comparison to aluminum copper is heavy and expensive. In particular for fully electric vehicles the switch to the cheaper and lighter aluminum would be an interesting option. That is why the optimization of intricate power supply networks is now in the focus of engineering research. Scientists from the Technische Universitaet Muenchen (TUM), in collaboration with BMW engineers, have now found out what tricks make it possible to replace copper with aluminum.

Electric power and electronics are playing an ever-increasing role in all kinds of vehicles. Currently copper is the conductive material of choice. But in comparison to aluminum copper is heavy and expensive. In particular for fully electric vehicles the switch to the cheaper and lighter aluminum would be an interesting option. That is why the optimization of intricate power supply networks is now in the focus of engineering research. Scientists from the Technische Universitaet Muenchen (TUM), in collaboration with BMW engineers, have now found out what tricks make it possible to replace copper with aluminum.

At first glance it is not at all clear why copper is still used as conductor in modern electric or semi-electric vehicles — when aluminum is lighter and significantly less costly. However, before aluminum can replace copper in power supply systems, a number of technological challenges need to be surmounted. When temperatures are high — and there are many places in a car where that is the case — aluminum displays a distinct creep behavior. Conventional connectors could thus not be used, as they would become loose with time.

One possible alternative — the use of aluminum-based elements in cables and copper-based elements in connection areas — also entails problems. Because there is a high electrochemical potential between a copper contact and an aluminum cable, this kind of wiring would be very prone to corrosion. Besides, joining copper to aluminum is rather demanding with the current state of technology. In order to counteract the aforementioned difficulties, scientists of the chairs for High Voltage Technology and Power Transmission and for Metal Casting and Forming, in cooperation with the respective departments of the BMW Group, developed an innovative aluminum-based electrical connection concept in the project LEIKO.

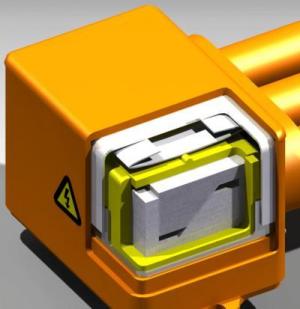

A sheet metal cage, which is an electromagnetic compatibility requirement anyway, enhances the mechanical stability of the plug and guarantees the long-term support of the contact pressure spring. Because the necessary contact force is no longer provided by the contact elements themselves, the originally problematic creep behavior of aluminum turns into a contact stabilizing, and thus, positive property. This, in turn, also guarantees a constant contact force over a lifetime of ten years.