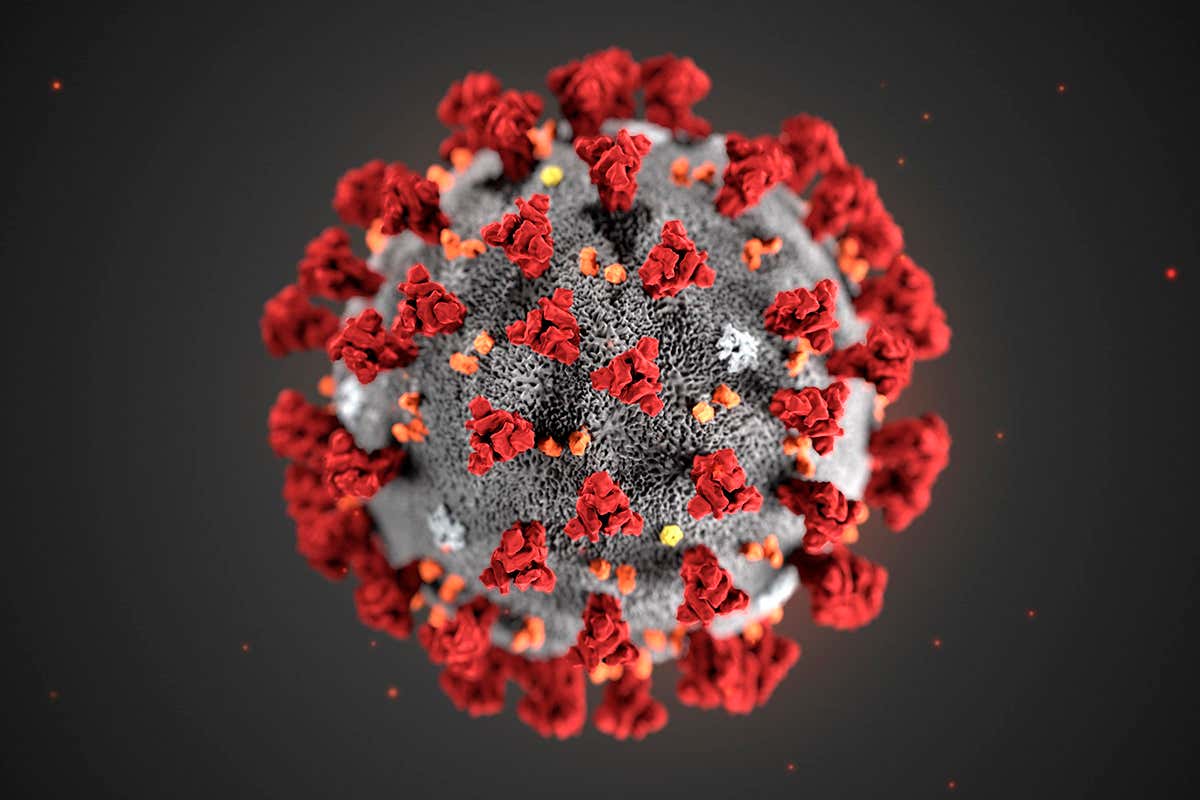

When woven into clothes, piezoelectric fibres will transform mechanical energy into electric energy every time a person moves.

Credit: Katharina Maisenbacher, Max Planck Institute

Scientists have found a way to generate electricity from nylon, raising hopes that the clothes on our backs will become an important source of energy.

Researchers have found a way to produce nylon fibres that are smart enough to produce electricity from simple body movement, paving the way for smart clothes that will monitor our health through miniaturised sensors and charge our devices without any external power source.

This discovery – a collaboration between the University of Bath, the Max Planck Institute for Polymer Research in Germany and the University of Coimbra in Portugal – is based on breakthrough work on solution-processed piezoelectric nylons led by Professor Kamal Asadi from the Department of Physics at Bath and his former PhD student Saleem Anwar.

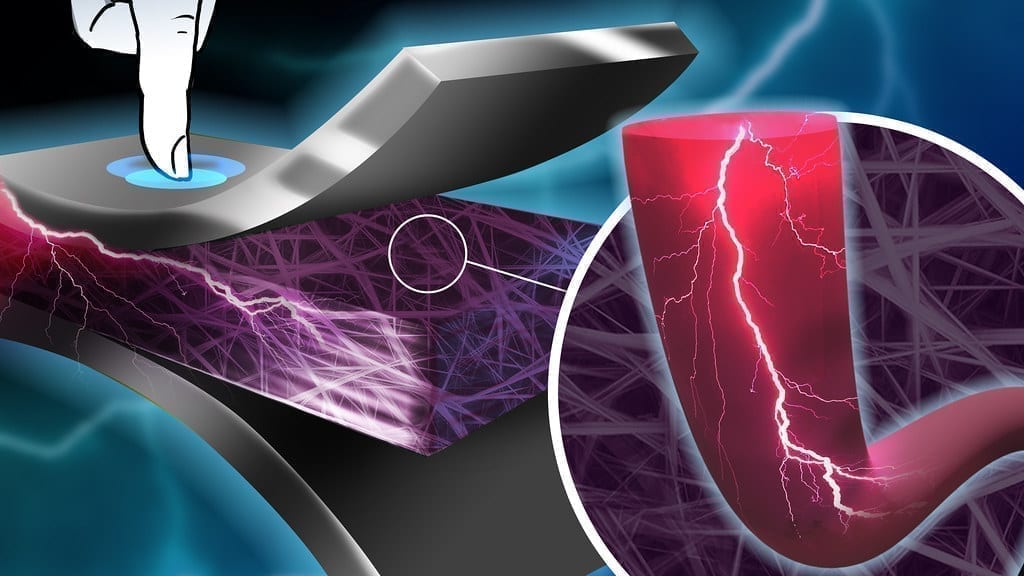

Piezoelectricity describes the phenomenon where mechanical energy is transformed into electric energy. To put it simply, when you tap on or distort a piezoelectric material, it generates a charge. Add a circuit and the charge can be taken away, stored in a capacitor for instance and then put to use – for example, to power your mobile phone.

While wearing piezoelectric clothing, such as a shirt, even a simple movement like swinging your arms would cause sufficient distortions in the shirt’s fibres to generate electricity.

Professor Asadi said: “There’s growing demand for smart, electronic textiles, but finding cheap and readily available fibres of electronic materials that are suitable for modern-day garments is a challenge for the textile industry.

“Piezoelectric materials make good candidates for energy harvesting from mechanical vibrations, such as body motion, but most of these materials are ceramic and contain lead, which is toxic and makes their integration in wearable electronics or clothes challenging.”

Scientists have been aware of the piezoelectric properties of nylon since the 1980s, and the fact that this material is lead-free and non-toxic has made it particularly appealing. However, the silky, man-made fabric often associated with cheap T-shirts and women’s stockings is “a very difficult material to handle”, according to Professor Asadi.

“The challenge is to prepare nylon fibres that retain their piezoelectric properties,” he said.

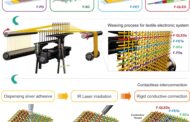

In its raw polymer form, nylon is a white powder that can be blended with other materials (natural or man-made) and then moulded into myriad products, from clothes and toothbrush bristles to food packaging and car parts. It’s when nylon is reduced to a particular crystal form that it becomes piezoelectric. The established method for creating these nylon crystals is to melt, rapidly cool and then stretch the nylon. However this process results in thick slabs (known as ‘films’) that are piezoelectric but not suited to clothing. The nylon would need to be stretched to a thread to be of woven into garments, or to a thin film to be used in wearable electronics.

The challenge of producing thin piezoelectric nylon films was thought to be insurmountable, and initial enthusiasm for creating piezoelectric nylon garments turned to apathy, resulting in research in this area virtually grinding to a halt in the 1990s.

On a whim, Professor Asadi and Mr Anwar – a textile engineering– took a completely new approach to producing piezoelectric nylon thin films. They dissolved the nylon powder in an acid solvent rather than by melting it. However, they found that the finished film contained solvent molecules that were locked inside the materials, thereby preventing formation of the piezoelectric phase.

“We needed to find a way to remove the acid to make the nylon useable,” said Professor Asadi, who started this research at the Max Planck Institute for Polymer Research in Germany before moving to Bath in September.

By chance, the pair discovered that by mixing the acid solution with the acetone (a chemical best known as a paint thinner or nail varnish remover), they were able to dissolve the nylon and then extract the acid efficiently, leaving the nylon film in a piezoelectric phase.

“The acetone bonds very strongly to the acid molecules, so when the acetone is evaporated from nylon solution, it takes the acid with it. What you’re left with is nylon in its piezoelectric crystalline phase. The next step is to turn nylon into yarns and then integrate it into fabrics.”

Developing piezoelectric fibres is a major step towards being able to produce electronic textiles with clear applications in the field of wearable electronics. The goal is to integrate electronic elements, such as sensors, in a fabric, and to generate power while we’re on the move. Most likely, the electricity harvested from the fibres of piezoelectric clothing would be stored in a battery nestled in a pocket. This battery would then connect to a device either via a cable or wirelessly.

“In years to come, we could be using our T-shirts to power a device such as our mobile phone as we walk in the woods, or for monitoring our health,” said Professor Asadi.

The Latest Updates from Bing News & Google News

Go deeper with Bing News on:

Electricity from nylon

- Dior Is Undeniably French, But It’s Also Surprisingly New York

These moments are also what makes the city magnetic, giving it its famous push-and-pull force. It’s the kind of energy that’s drawn visionaries for centuries, the kind from which new paths are forged.

- Music Review: Anitta welcomes listeners into her ‘Funk Generation’ on new album

First, she took over Brazil. Now, the world. The trilingual Brazilian pop star Anitta has returned with a new album, the club-to-bedroom ready “Funk Generation.” ...

- From Apple and Casio to recycling running shoes, how sustainable is fitness tech in 2024?

The use of recycled materials in outdoor tech is growing and it's clear why that is a very good thing all round.

- Capitalize on the Growing Demand: Textile Recycling Market Poised for 3.2% CAGR by 2033

The textile recycling market was worth US$ 4.8 billion in 2023 and is expected to reach US$ 6.6 billion by 2033 at a CAGR of 3.2% between 2023 and 2033. The US is known for producing nearly 25 billion ...

- Best running shorts for women of 2024, tested by editors

We logged more than 10 miles in eight pairs of the most popular running shorts and landed on these four options as the best for their comfort, style, utility and performance.

Go deeper with Google Headlines on:

Electricity from nylon

[google_news title=”” keyword=”electricity from nylon” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]

Go deeper with Bing News on:

Electronic textiles

- E-Textile Market Size to Grow USD 5238.3 Million by 2029 at a CAGR of 8% | Valuates Reports

E-Textile Market is Segmented by Type (Passive Electronic Textiles, Active Electronic Textiles, Ultra-Electronic Textiles), by Application (Military Uses, Civil Uses, Healthcare Uses).

- Extracting Pure Gold From Electrical Trash Just Got Easier

Using fibers, researchers can extract nearly 100 percent of gold from electronic waste, much more than previous methods.

- Eastman Taps Debrand for Textile Recycling Pilot

Eastman and Debrand have teamed up to turn 5,000 pounds of textile waste into Naia Renew fibers through molecular recycling.

- Machine learning used to create a fabric-based touch sensor

A new fabric-based touch sensor used machine learning to control mobile apps, video games and other devices while integrated into clothing.

- Threads to tech: Researchers play video game with just a piece of fabric

A s wearable technology becomes increasingly in demand, so have smart textiles. NC State researchers just took smart fabrics to a whole new level of sophistication—they played a video game with a tiny ...

Go deeper with Google Headlines on:

Electronic textiles

[google_news title=”” keyword=”electronic textiles” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]