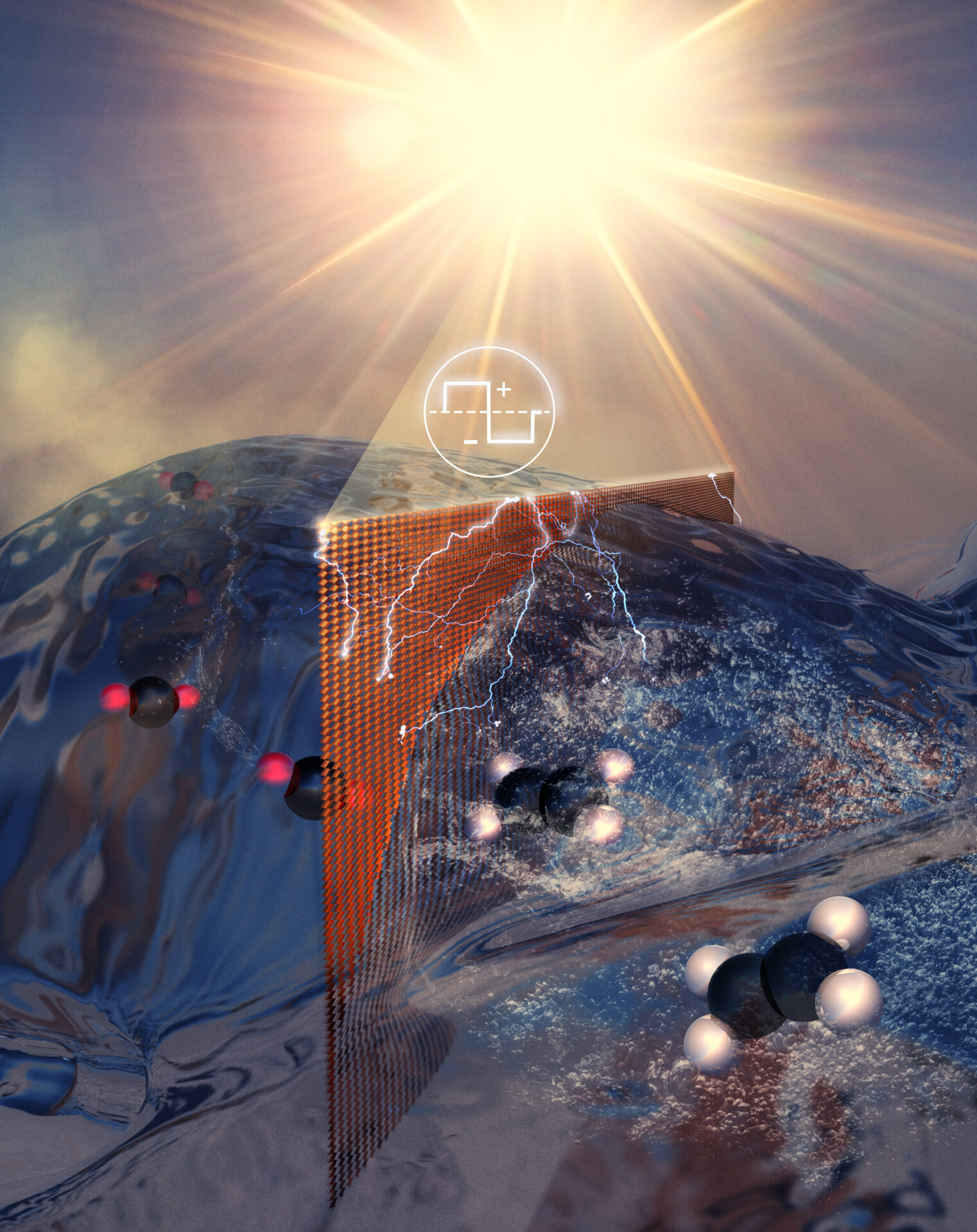

Abstract illustration of atoms passing through water and an electrified membrane under a shining sun.

Illustration: Meenesh Singh.

A team of researchers led by Meenesh Singh at University of Illinois Chicago has discovered a way to convert 100% of carbon dioxide captured from industrial exhaust into ethylene, a key building block for plastic products.

Their findings are published in Cell Reports Physical Science.

While researchers have been exploring the possibility of converting carbon dioxide to ethylene for more than a decade, the UIC team’s approach is the first to achieve nearly 100% utilization of carbon dioxide to produce hydrocarbons. Their system uses electrolysis to transform captured carbon dioxide gas into high purity ethylene, with other carbon-based fuels and oxygen as byproducts.

The process can convert up to 6 metric tons of carbon dioxide into 1 metric ton of ethylene, recycling almost all carbon dioxide captured. Because the system runs on electricity, the use of renewable energy can make the process carbon negative.

According to Singh, his team’s approach surpasses the net-zero carbon goal of other carbon capture and conversion technologies by actually reducing the total carbon dioxide output from industry. “It’s a net negative,” he said. “For every 1 ton of ethylene produced, you’re taking 6 tons of CO2 from point sources that otherwise would be released to the atmosphere.”

Previous attempts at converting carbon dioxide into ethylene have relied on reactors that produce ethylene within the source carbon dioxide emission stream. In these cases, as little as 10% of CO2 emissions typically converts to ethylene. The ethylene must later be separated from the carbon dioxide in an energy-intensive process often involving fossil fuels.

In UIC’s approach, an electric current is passed through a cell, half of which is filled with captured carbon dioxide, the other half with a water-based solution. An electrified catalyst draws charged hydrogen atoms from the water molecules into the other half of the unit separated by a membrane, where they combine with charged carbon atoms from the carbon dioxide molecules to form ethylene.

Among manufactured chemicals worldwide, ethylene ranks third for carbon emissions after ammonia and cement. Ethylene is used not only to create plastic products for the packaging, agricultural and automotive industries, but also to produce chemicals used in antifreeze, medical sterilizers and vinyl siding for houses.

Ethylene is usually made in a process called steam cracking that requires enormous amounts of heat. Cracking generates about 1.5 metric tons of carbon emissions per ton of ethylene created. On average, manufacturers produce around 160 million tons of ethylene each year, which results in more than 260 million tons of carbon dioxide emissions worldwide.

In addition to ethylene, the UIC scientists were able to produce other carbon-rich products useful to industry with their electrolysis approach. They also achieved a very high solar energy conversion efficiency, converting 10% of energy from the solar panels directly to carbon product output. This is well above the state-of-the-art standard of 2%. For all the ethylene they produced, the solar energy conversion efficiency was around 4%, approximately the same rate as photosynthesis.

Original Article: A breakthrough discovery in carbon capture conversion for ethylene production

More from: University of Illinois at Chicago

The Latest Updates from Bing News

Go deeper with Bing News on:

CO2 to ethylene

- Exxon is working on tech to remove CO2 from atmosphere but a breakthrough is needed to slash costs

Exxon CEO Darren Woods said the technology is currently unaffordable with CO2 removal costing between $600 to $1,000 per ton.

- New electrochemical reactor converts CO2 into usable materials

Recovery of CO2 from carbon capture plants is technically complex and expensive to execute. A new approach will make it economically feasible.

- New approach could make reusing captured carbon far cheaper, less energy-intensive

Engineers at Georgia Tech have designed a process that converts carbon dioxide removed from the air into useful raw material that could be used for new plastics, chemicals, or fuels.

- Regulators deny late requests to delay carbon dioxide pipeline decision

In a split vote, the Iowa Utilities Board declined to solicit more evidence before it decides whether to issue a pipeline permit to Summit Carbon Solutions, according to a Thursday board order. In ...

- Coal and new gas power plants will have to meet climate pollution targets

Fifteen years after the EPA said greenhouse gasses are a danger to public health, the agency finalized rules to limit climate-warming pollution from existing coal and new gas power plants.

Go deeper with Bing News on:

Carbon capture conversion

- CO2 capture projects at Wyoming coal plant receive funding

Basin Electric Power Cooperative's coal-fired Dry Fork Station hosts a CCS testing facility which allows CO2 capture technology companies access to the flue gas that would otherwise be released from ...

- New $60m lab in S’pore to drive R&D in carbon capture, biofuels and hydrogen

Transforming Singapore’s energy and chemical sectors will be a priority, says DPM Heng Swee Keat. Read more at straitstimes.com.

- Missoula company lands DOE grant to advance carbon capture tech

A tech company based in Missoula landed a share of an $8 million federal grant on Friday from the U.S. Department of Energy to advance carbon capture technologies in the nation's pursuit of net-zero ...

- Germany plans bilateral debt reforms to push global climate investments

Germany plans to change its bilateral debt relief framework to enable middle-income countries to benefit from climate investment, Chancellor Olaf Scholz said on Friday.

- West Virginia researchers leading the way in carbon capture technology for cleaner energy future

The U.S. Environmental Protection Agency has proposed new rules that would require coal and natural gas power plants to cut or capture almost all carbon dioxide emissions by 2038. Congress approved $3 ...