Image: Daniel Preston/Device Research Lab

New technique offers precise, durable control over tiny mirrors or stages.

Microelectromechanical systems, or MEMS, are tiny machines fabricated using equipment and processes developed for the production of electronic chips and devices. They’ve found a wide variety of applications in today’s consumer electronics, but their moving parts can wear out over time as a result of friction.

A new approach developed by researchers at MIT could offer a new way of making movable parts with no solid connections between the pieces, potentially eliminating a major source of wear and failure.

The new system uses a layer of liquid droplets to support a tiny, movable platform, which essentially floats on top of the droplets. The droplets can be water or some other fluid, and the precise movements of the platform can be controlled electrically, through a system that can alter the dimensions of the droplets to raise, lower, and tilt the platform.

The new findings are reported in a paper in Applied Physics Letters, co-authored by Daniel Preston, an MIT graduate student; Evelyn Wang, the Gail E. Kendall Associate Professor of Mechanical Engineering; and five others.

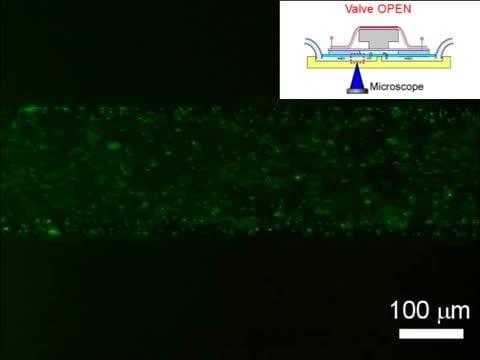

Video: Melanie Gonick/MIT

Preston explains that the new system could be used to make devices such as stages for microscope specimens. The focus of the microscope could be controlled by raising or lowering the stage, which would involve changing the shapes of supporting liquid droplets.

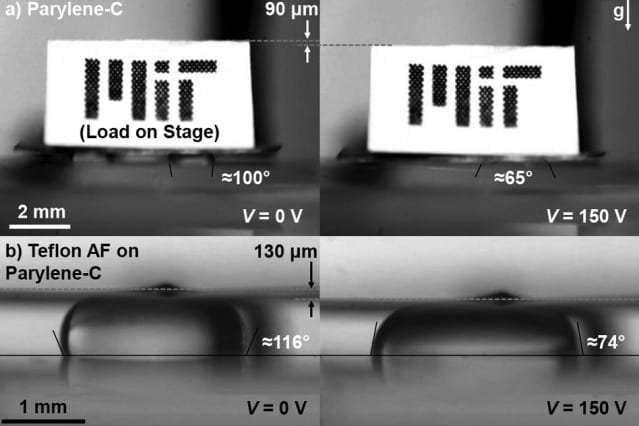

The system works by altering the way the droplets interact with the surface below them, governed by a characteristic known as the contact angle. This angle is a measure of how steep the edge of the droplet is at the point where it meets the surface. On hydrophilic, or water-attracting, surfaces, droplets spread out nearly flat, producing a very small contact angle, while hydrophobic, or water-repelling, surfaces cause droplets to be nearly spherical, barely touching the surface, with very large contact angles. On certain kinds of dielectric surfaces, these qualities can be “tuned” across that whole range by simply varying a voltage applied to the surface.

As the surface gets more hydrophobic and the droplets get rounder, their tops rise farther from the surface, thus raising the platform — in these tests, a thin sheet of copper — that floats on them. By selectively changing different droplets by different amounts, the platform can also be selectively tilted. This could be used, for example, to change the angle of a mirrored surface in order to aim a laser beam, Preston says. “There are a lot of experiments that use lasers, that could really benefit from a way to make these small-scale movements.”

The new system could be used to make devices such as stages for microscope specimens. The focus of the microscope could be controlled by raising or lowering the stage, which would involve changing the shapes of supporting liquid droplets. (Image: Daniel Preston/Device Research Lab)

In order to maintain the positioning of the droplets rather than letting them slide around, the team treated the underside of the floating platform. They made the overall surface hydrophobic, but with small circles of hydrophilic material. That way, all the droplets are securely “pinned” to those water-attracting surfaces, keeping the platform securely in position.

In the group’s initial test device, the vertical positioning can be controlled to within a precision of 10 microns, or millionths of a meter, over a range of motion of 130 microns.

MEMS devices, Preston says, “often fail when there’s a solid-solid contact that wears out, or just gets stuck. At these very small scales, things break down easily.”

While the basic technology behind the alteration of droplet shapes on a surface is not a new idea, Preston says, “nobody has used it to move a stage, without any solid-solid contact. The real innovation here is being able to move a stage up and down, and change its angle, without any solid material connections.”

In principle, it would be possible to use a large array of electrodes that could be adjusted to move a platform across a surface in precise ways, in addition to up and down. For example, it could be used for “lab on a chip” applications, where a biological sample could be mounted on the platform and then moved around from one test site to another on the microchip.

He says the system is relatively simple to implement and that it would be possible to develop it for specific real-world application fairly rapidly. “It depends how motivated people are,” he says. “But I don’t see any huge barriers to large-scale use. I think it could be done within a year.”

“Controlled movements of a stage in microscale are difficult, because the miniature versions of the familiar motors and gear mechanisms do not exist, and if they existed, they would be too weak and frictional, respectively,” says Chang-Jin Kim, a professor of mechanical and aerospace engineering at the University of California at Los Angeles, who was not involved in this research. “Since this challenge is rather fundamental, it is only logical (albeit exotic) to use liquid droplets as a mechanical element,” he says. “There are numerous questions remaining before this stage becomes practical, but this is a good start proving the main design concept.”

“This approach is simpler and hence is expected to provide a significant cost benefit over existing techniques in practical applications,” says Prosenjit Sen, an assistant professor at the Centre for Nano Science and Engineering at the Indian Institute of Science, who also was not involved in this work. “The use of droplet supports additionally provides some degree of vibration isolation, which is not possible in all-solid stages.”

Learn more: Movable microplatform floats on a sea of droplets

[osd_subscribe categories=’mems’ placeholder=’Email Address’ button_text=’Subscribe Now for any new posts on the topic “MEMS”‘]

Receive an email update when we add a new MEMS article.

The Latest on: Microelectromechanical systems

[google_news title=”” keyword=”microelectromechanical systems” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Microelectromechanical systems

- Nvidia Supplier SK Hynix Says HBM Chips Almost Sold Out for 2025on May 2, 2024 at 1:54 am

South Korea's SK Hynix said on Thursday that its high-bandwidth memory (HBM) chips used in AI chipsets were sold out for this year and almost sold out for 2025 as businesses aggressively expand ...

- Buy Rating Affirmed for Knowles Corporation on Revenue Rebound and Strategic Acquisitionson May 1, 2024 at 6:15 pm

Knowles (KN – Research Report), the Technology sector company, was revisited by a Wall Street analyst yesterday. Analyst Tristan Gerra ...

- Positive outlook for Dnexon May 1, 2024 at 3:00 pm

Despite recording its lowest net profit in three years, Dagang NeXchange Bhd (Dnex) remains optimistic about its future prospects backed by the global semiconductor market recovery, favourable oil ...

- Amkor Technology, Inc. (NASDAQ:AMKR) Q1 2024 Earnings Call Transcripton May 1, 2024 at 5:21 am

Thomas Diffely: I guess first another margin question for Megan. When you look at the ramp in Vietnam over the next several quarters, and I know that some costs are already in the system, but how do ...

- Nepalis Fight TikTok Ban in Court, or Ignore It Entirelyon May 1, 2024 at 4:16 am

When Nepal suddenly announced a ban on TikTok last year, lawyer Sunil Rajan Singh was determined to fight what he said was a government effort to hide its wrongdoings. The hugely popular video-sharing ...

- Era of earbud compromises now over; Skyline, xMEMS solid-state acoustic vent, enables earbuds that excel in every situationon April 29, 2024 at 11:45 pm

MEMS introduced the Skyline DynamicVent in 2023 to solve many of the unaddressed consumer experience issues with TWS earbuds. Skyline is a novel, but straightforward extension of xMEMS' innovative ...

- USound and Minami Sign Partnership to Facilitate New Collaborations with Top-Tier Brandson April 29, 2024 at 11:03 pm

USound, the leading global provider of MEMS (micro-electromechanical system) speakers, announced today its partnership with Minami Acoustics Limited, the renowned Original Design Manufacturer (ODM) ...

- Micro-Electro-Mechanical System (MEMS) Market Size, Share, Industry Growth, 2029on April 29, 2024 at 6:30 pm

The Micro-electro-mechanical System (MEMS) market Size is projected to grow from USD 16.5 billion in 2024 and is projected to reach USD 24.2 billion by 2029; it is expected to grow at a CAGR of 7.9% ...

- Underwater mass spectrometry achieves 500-fold sensitivity enhancement for dissolved methane detectionon April 29, 2024 at 1:35 pm

A research team led by Prof. Chen Chilai from Hefei Institutes of Physical Science of Chinese Academy of Sciences, amplified the detection sensitivity of dissolved methane in water by over 500 times, ...

via Bing News