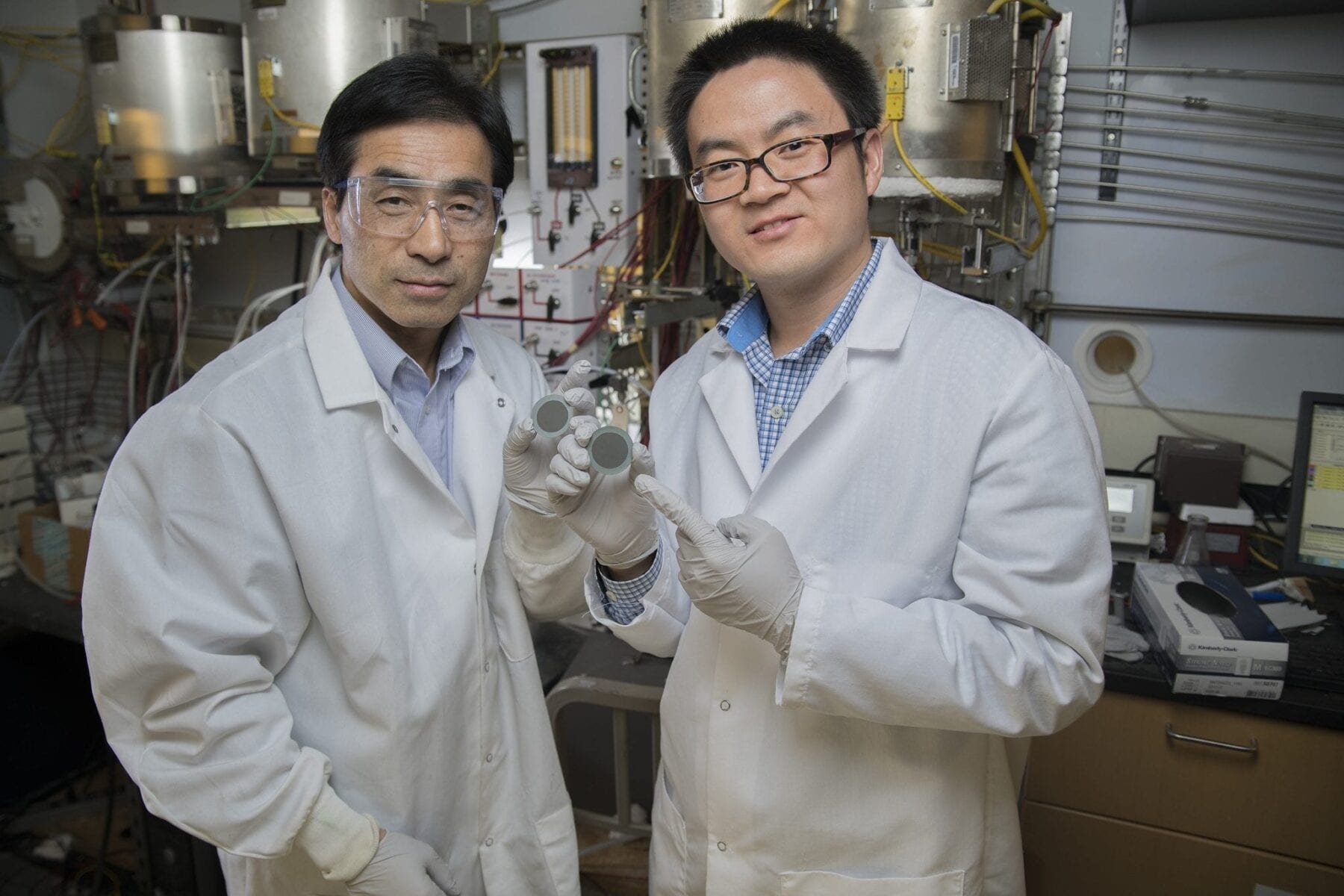

Dr. Tarek Loubani has worked as an emergency room physician in hospitals during some of their most desperate times. In 2012, he was practising in a hospital in Gaza, and found himself sharing his one stethoscope with ten other doctors who were trying to treat more than 100 patients.

“We weren’t just low on medical supplies, but even the basics, like stethoscopes, were totally missing,” said Loubani, who is an associate professor at Western’s Schulich School of Medicine & Dentistry, associate scientist at Lawson Health Research Institute and an emergency room physician at London Health Sciences Centre.

Loubani decided he needed to find a way health care providers could create their own supplies on site and eliminate the medical supply chain when access to medical supplies was limited.

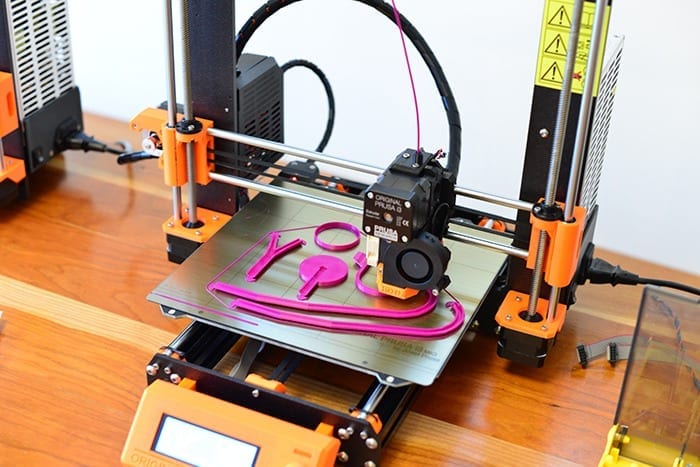

He remembers vividly when a solution came into clear view: the day he was playing with a toy stethoscope and noticed that it performed its function quite well. That was the genesis of the idea that led him and his team to create an open-access template for a 3D-printed stethoscope that could be created using recycled plastic.

Now, the team’s stethoscope has been clinically validated, and their results are published in the journal PLOS ONE.

“As far as we know this is the first open-source medical device that has been clinically validated,” said Loubani. “We wanted physicians and allied health care professionals to be able to have something that was high quality. We found that the acoustic quality was the same in our stethoscope as in a premium brand stethoscope.”

The stethoscope is currently being used by physicians and allied health professionals in Gaza and also here in London at the London Health Sciences Centre.

Loubani says stethoscopes may not been seen as vital for diagnosis and treatment in places such as London, where physicians rely heavily on ultrasound, CT and other diagnostic technologies. However, in war-torn and low-income countries, it is a necessary tool.

“Stethoscope utility goes up as other resources go down. In London, if someone gets shot, I can use an ultrasound and look inside and see if there is a life-threating air pocket called a pneumothorax. In Gaza, ultrasounds are not available in the emergency department, or are dilapidated, so the stethoscope becomes an inexpensive tool that allows us to make life-saving decisions.”

The hope now, is to create templates for other medical devices that can be made or improved on-site, he said.

Learn more: Innovative 3D-printed stethoscope saves lives

The Latest on: Open-source medical device

[google_news title=”” keyword=”open-source medical device” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on:

Open-source medical device

- Insights from The Identity Jedi for shoring up healthcare's cybersecurity defenseson April 30, 2024 at 9:29 am

David Lee, The Identity Jedi and Chief Evangelist and Visionary for Tech Diversity, observes, "Healthcare is an outlier in cybersecurity because they're often playing catch-up due to their reliance on ...

- Autonomous blood drawing device developer Vitestro raises $22Mon April 30, 2024 at 4:00 am

Autonomous blood drawing company Vitestro believes the answer to that lies in robotics.

- iFabric Corp. Receives FDA Medical Device Registration for Apparel Products Utilizing Multiple Textile Technologieson April 30, 2024 at 3:41 am

MARKHAM, ON / ACCESSWIRE / April 30, 2024 / iFabric Corp. ("iFabric" or the "Company") (TSX:IFA.TO)(OTCQX:IFABF), a leading provider of innovative apparel and textile technologies, announces its ...

- Philips will pay $1.1 billion to resolve US lawsuits over breathing machines that expel debrison April 29, 2024 at 2:52 pm

Medical device maker Philips will pay $1.1 billion to settle personal injury lawsuits in the U.S. over its defective sleep apnea machines.

- HiddenLayer Uncovers Deserialization Vulnerability in Open-Source Programming Language, Ron April 29, 2024 at 6:46 am

Vulnerability Threatens Users in Critical Government, Medical, and Financial Sectors ...

- FDA Proposes Updated Guidance Concerning Cybersecurity of Medical Deviceson April 28, 2024 at 5:00 pm

The U.S. Food and Drug Administration ("FDA") has proposed updated guidance, intended to assist individuals in meeting the cybersecurity requirements for FDA medical device submissions. On March 13, ...

- Align Technology Announces $150 Million Open Market Repurchaseon April 26, 2024 at 5:33 am

Today’s announcement of Align’s $150 million open market repurchases reflects the strength of our balance sheet and cash flow generation, as well as management’s and the Board’s continued confidence ...

- EU investigates fair access to China's medical device marketon April 24, 2024 at 7:05 am

The European Commission launched a probe into China's public procurement of medical devices on Wednesday, the latest in a series of moves that ratchet up trade tensions ahead of President Xi Jinping's ...

- The EU will probe whether China is unfairly denying companies access to its medical devices marketon April 24, 2024 at 4:53 am

The European Union says it will investigate whether China is using unfair methods to deprive companies in Europe of access to its market for medical devices.

via Bing News