“Now is a critical time to develop promising solutions for sustainable humanity,” Yang notes. “This year, we witnessed heat waves and record-breaking temperatures in North America, Europe, Asia, and Australia. It is essential that we find solutions to this climate challenge, and we are very excited to be working on this new technology that addresses it.”

Yu adds that he used to think that white was the most unattainable color: “When I studied watercolor painting years ago, white paints were the most expensive. Cremnitz white or lead white was the choice of great masters, including Rembrandt and Lucian Freud. We have now demonstrated that white is in fact the most achievable color. It can be made using nothing more than properly sized air voids embedded in a transparent medium. Air voids are what make snow white and Saharan silver ants silvery.”

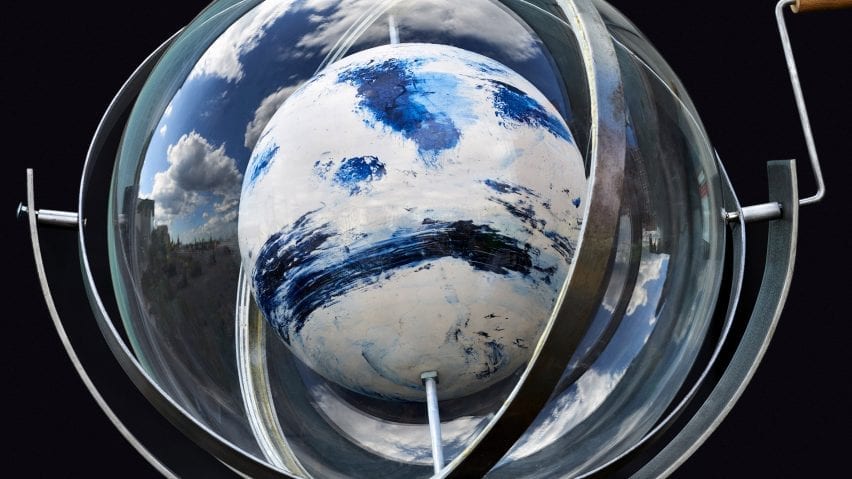

Columbia Engineers make white paint whiter—and cooler—by removing white pigment and invent a polymer coating, with nano-to-microscale air voids, that acts as a spontaneous air cooler and can be fabricated, dyed, and applied like paint.

With temperatures rising and heat-waves disrupting lives around the world, cooling solutions are becoming ever more essential. This is a critical issue especially in developing countries, where summer heat can be extreme and is projected to intensify. But common cooling methods such as air conditioners are expensive, consume significant amounts of energy, require ready access to electricity, and often require coolants that deplete ozone or have a strong greenhouse effect.

An alternative to these energy-intensive cooling methods is passive daytime radiative cooling (PDRC), a phenomenon where a surface spontaneously cools by reflecting sunlight and radiating heat to the colder atmosphere. PDRC is most effective if a surface has a high solar reflectance (R) that minimizes solar heat gain, and a high, thermal emittance (?) that maximizes radiative heat loss to the sky. If R and ? are sufficiently high, a net heat loss can occur, even under sunlight.

Developing practical PDRC designs has been challenging: many recent design proposals are complex or costly, and cannot be widely implemented or applied on rooftops and buildings, which have different shapes and textures. Up to now, white paints, which are inexpensive and easy to apply, have been the benchmark for PDRC. White paints, however, usually have pigments that absorb UV light, and do not reflect longer solar wavelengths very well, so their performance is only modest at best.

Researchers at Columbia Engineering have invented a high-performance exterior PDRC polymer coating with nano-to-microscale air voids that acts as a spontaneous air cooler and can be fabricated, dyed, and applied like paint on rooftops, buildings, water tanks, vehicles, even spacecraft—anything that can be painted. They used a solution-based phase-inversion technique that gives the polymer a porous foam-like structure. The air voids in the porous polymer scatter and reflect sunlight, due to the difference in the refractive index between the air voids and the surrounding polymer. The polymer turns white and thus avoids solar heating, while its intrinsic emittance causes it to efficiently lose heat to the sky. The study is published online today in Science.

Passive daytime radiative cooling (PDRC) involves simultaneously reflecting sunlight and radiating heat into the cold sky to achieve a net heat loss. The process, which is spontaneous, can cool down structures to sub-ambient temperatures.

“This simple but fundamental modification yields exceptional reflectance and emittance that equal or surpass those of state-of-the-art PDRC designs, but with a convenience that is almost paint-like,” says Mandal.

The researchers found their polymer coating’s high solar reflectance (R > 96%) and high thermal emittance (? ~ 97%) kept it significantly cooler than its environment under widely different skies, e.g. by 6?C in the warm, arid desert in Arizona and 3?C in the foggy, tropical environment of Bangladesh. “The fact that cooling is achieved in both desert and tropical climates, without any thermal protection or shielding, demonstrates the utility of our design wherever cooling is required,” Yang notes.

The team also created colored polymer coatings with cooling capabilities by adding dyes. “Achieving a superior balance between color and cooling performance over current paints is one of the most important aspects of our work,” Yu notes. “For exterior coatings, the choice of color is often subjective, and paint manufacturers have been trying to make colored coatings, like those for roofs, for decades.”

The group took environmental and operational issues, such as recyclability, bio-compatibility, and high-temperature operability, into consideration, and showed that their technique can be generalized to a range of polymers to achieve these functionalities. “Polymers are an amazingly diverse class of materials, and because this technique is generic, additional desirable properties can be conveniently integrated into our PDRC coatings, if suitable polymers are available,” Mandal adds.

“Nature offers many ways for heating and cooling, some of which are extremely well known and widely studied and others that are poorly known. Radiative cooling—by using the sky as a heat sink—belongs to the latter group, and its potential has been strangely overlooked by materials scientists until a few years ago,” says Uppsala University Physics Professor Claes-Göran Granqvist, a pioneer in the field of radiative cooling, who was not involved with the study. “The publication by Mandal et al. highlights the importance of radiative cooling and represents an important breakthrough by demonstrating that hierarchically porous polymer coatings, which can be prepared cheaply and conveniently, give excellent cooling even in full sunlight.”

Yang, Yu, and Mandal are refining their design in terms of applicability, while exploring possibilities such as the use of completely biocompatible polymers and solvents. They are in talks with industry about next steps.

“Now is a critical time to develop promising solutions for sustainable humanity,” Yang notes. “This year, we witnessed heat waves and record-breaking temperatures in North America, Europe, Asia, and Australia. It is essential that we find solutions to this climate challenge, and we are very excited to be working on this new technology that addresses it.”

Yu adds that he used to think that white was the most unattainable color: “When I studied watercolor painting years ago, white paints were the most expensive. Cremnitz white or lead white was the choice of great masters, including Rembrandt and Lucian Freud. We have now demonstrated that white is in fact the most achievable color. It can be made using nothing more than properly sized air voids embedded in a transparent medium. Air voids are what make snow white and Saharan silver ants silvery.”

Learn more: Polymer Coating Cools Down Buildings

The Latest on: Passive daytime radiative cooling

[google_news title=”” keyword=”passive daytime radiative cooling” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Passive daytime radiative cooling

- Towngas backs TERA-Award winner i2Cool in Series A to drive global green energy expansionon May 9, 2024 at 8:12 am

The Hong Kong and China Gas Company Limited (Towngas) is pleased to announce its participation in the Series A funding round ...

- Reducing PV module temperature with radiative cooling based on polymeric coatingson April 16, 2024 at 5:01 pm

Researchers from the King Abdulaziz University in Saudi Arabia investigated the use of polymeric coatings for passive radiative cooling (PRC) of PV modules. Radiative cooling occurs when the ...

- $8 Raspberry Pi 5 Passive Cooling Open CNC caseon April 10, 2024 at 5:00 pm

If you are searching for a way to keep your Raspberry Pi mini PC components cool at an affordable price you might be interested in a new $8 Pi 5 passive cooling case aptly named the Passive ...

- 5 next-gen passive cooling techniques to chill buildings for freeon April 4, 2024 at 12:13 pm

For example, ancient Hittite buildings in modern-day ... (radiative cooling) to transfer heat from the device directly through the air and into space. Another interesting development in high-tech ...

- Intelligent metasurfaces enable ultra-high performance passive radiative coolingon April 4, 2024 at 11:27 am

2024.230194, discusses intelligent metasurfaces enable ultra-high performance passive radiative cooling. Daytime passive radiative cooling is a recently demonstrated disruptive technology that ...

- The chameleon’s guide to making buildings greenon December 20, 2023 at 4:58 am

It could one day help bring down the energy use of heating and cooling ... on small building models along with white paint, blue steel tiles, and a passive radiative cooling paint. They placed the ...

- How To Survive A Wet Bulb Eventon July 27, 2023 at 12:14 am

What you learn here could end up saving your life one day. The body has methods of maintaining ... Our body’s inbuilt cooling system is an amazing thing. In extremely dry, low-humidity ...

- Cooling Paint You Can Actually Makeon July 3, 2023 at 9:37 am

[NightHawkInLight] has been working on radiative sky paint ... The result is a passive system that keeps materials a few degrees cooler in direct sunlight than an untreated piece in the shade.

- eLearning course on Passive Urban Cooling Solutions (Self-paced)on May 11, 2023 at 1:13 pm

(2) Technical Solutions to Urban Heat and Barriers to Implementing Them: This module will introduce the concept of passive and active urban cooling and present a series of technical solutions to ...

via Bing News