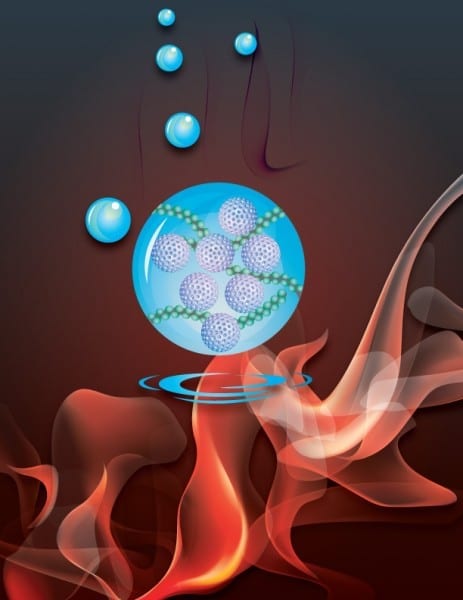

A new technology developed by Penn State researchers, called Cold Sintering Process (CSP), has opened a window on the ability to combine incompatible materials, such as ceramics and plastics, into new, useful compound materials, and to lower the energy cost of many types of manufacturing.

Ceramics is the oldest known man-made material, dating back tens of thousands of years. Throughout that time most all ceramics have been made by heating them to high temperatures, either by firing in kilns or sintering ceramic powders in furnaces, both of which require large amounts of energy.

“In this day and age, when we have to be incredibly conscious of the CO2 budget, the energy budget, rethinking many of our manufacturing processes, including ceramics, becomes absolutely vital,” said Clive Randall, professor of materials science and engineering at Penn State who developed the process with his team. “Not only is it a low temperature process (room temperature up to 200 degrees Celsius), but we are also densifying some materials to over 95 percent of their theoretical density in 15 minutes. We can now make a ceramic faster than you can bake a pizza, and at lower temperatures.”

In a recent article in the journal Advanced Functional Materials, Randall and his coauthors describe the co-sintering of ceramic and thermoplastic polymer composites using CSP. Three types of polymer were selected to complement the properties of three types of ceramics, a microwave dielectric, an electrolyte and a semiconductor, in order to highlight the diversity of applicable materials. These composite materials demonstrate new possibilities for dielectric property design, and both ionic and electronic electrical conductivity design. These composites can be sintered to high density at 120 degrees C in a time frame of 15 to 60 minutes.

Just add water

According to the researchers, the process involves wetting ceramic powder with a few drops of water or acid solution. The solid surfaces of the particles decompose and partially dissolve in the water to produce a liquid phase at particle-particle interfaces. Adding temperature and pressure causes the water to flow and the solid particles to rearrange in an initial densification process. Then in a second process, clusters of atoms or ions move away from where the particles are in contact, which aids diffusion, which then minimizes surface free energy, allowing the particles to pack tightly together. The key is knowing the exact combination of moisture, pressure, heat and time required to capture the reaction rates so the material fully crystallizes and gets to very high density.

“I see cold sintering process as a continuum of different challenges,” Randall said. “In some systems, it’s so easy you don’t need pressure. In others you do. In some you need to use nanoparticles. In others, you can get away with a mixture of nanoparticles and larger particles. It really all depends on the systems and chemistries you are talking about.”

The Penn State team has begun building a library of the precise techniques required to use CSP on various materials systems, with 50 processes verified to-date. These include ceramic-ceramic composites, ceramic-nanoparticle composites, ceramic-metals, as well as the ceramic-polymers discussed in this paper.

Other areas that are now open to exploration by CSP include architectural materials, such as ceramic bricks, thermal insulation, biomedical implants and many types of electronic components.

“My hope is that a lot of the manufacturing processes that already exist will be able to use this process, and we can learn from polymer manufacturing practices,” Randall concluded.

Learn more: LOWERING THE HEAT MAKES NEW MATERIALS POSSIBLE WHILE SAVING ENERGY

The Latest on: Cold Sintering Process

[google_news title=”” keyword=”Cold Sintering Process” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Cold Sintering Process

- Study: Zinc may reduce cold symptoms by two dayson May 9, 2024 at 7:01 am

Zinc might indeed reduce the duration of common cold symptoms by about two days, a new evidence review says. However, the evidence is not conclusive, and taking zinc can come with some unpleasant side ...

- Cold sintering may rescue plastic, ceramics, battery components from landfillson May 8, 2024 at 5:00 pm

Cold sintering — the process of combining powder-based materials into dense forms at low temperatures through applied pressure using solvents — allows for materials to be recycled again and again.

- Cold and Flu Newson May 7, 2024 at 5:00 pm

Mar. 26, 2024 — Simply asking patients to get the flu vaccine, and combining it with helpful video and print messages, is enough to persuade many who visit emergency departments to roll up their ...

- Penn State University Recognizes Five Faculty Members with Evan Pugh University Professorshipson May 4, 2024 at 5:17 am

Five Penn State professors have been named Evan Pugh University Professors, an elite and prestigious distinction conferred by the University on only 79 faculty members since the establishment of the ...

- 11 Best Cold Plunge Tubs in 2024on April 29, 2024 at 5:00 pm

If you buy through links on this page, we may earn a small commission. Here’s our process. Our best overall cold plunge tub honor goes to the aptly named Plunge, while your wallet might love the ...

- laser sinteringon April 24, 2023 at 5:01 pm

At the level pursued by many Hackaday readers, the advent of affordable 3D printing has revolutionised prototyping, as long as the resolution of a desktop printer is adequate and the part can be ...

- Hot & Cold Isostatic Pressingon March 8, 2022 at 9:30 am

This research CIP is used to shape form powders into a green body, prior to sintering. This model allows the pressing of various shapes, including discs, bars, and tubes, and is therefore a ...

- 6.4. Process Variableson February 25, 2018 at 12:55 pm

The most important factors involved during sintering process are temperature, time and furnace atmosphere. The influence of these factors on the sintering process is described below:5 Sintering ...

via Bing News