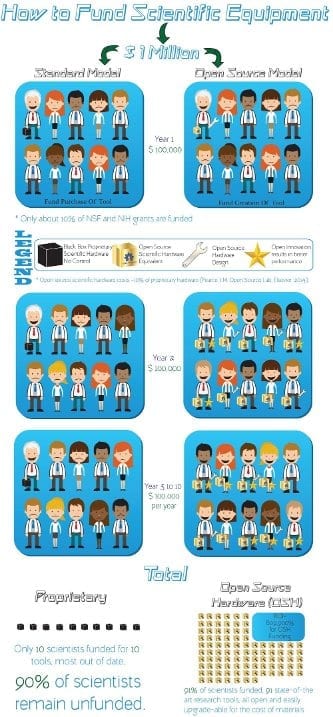

Science can be expensive. But making customized scientific equipment doesn’t have to be. Researchers at Michigan Technological University have compiled economic data on the effectiveness of open source hardware in the laboratory—and the process looks promising.

The new study, published in Science and Public Policy, was led by Joshua Pearce, an associate professor of materials science and engineering as well as electrical and computer engineering at Michigan Tech. Pearce says that distributed digital manufacturing of open source hardware will make science both cheaper and more accessible.

Open Source

Defining open source as “free” is too simple. While it does mean free access to papers, downloads and data, open source focuses primarily on sharing knowledge in order to refine and apply that knowledge. Free, or even inexpensive, is currently hard to come by in research.

“In science, we all have this problem where we pay so much for scientific equipment that it overwhelms our budgets,” Pearce says, explaining that a lot of equipment is simple—mechanically speaking—and can even be manufactured with a do-it-yourself 3-D printer like the RepRap.

Pearce proposes that instead of spending millions of dollars every year replacing quickly obsolescent equipment, that money could be redirected to developing open source tools that are “upgradeable and transformable—they will be continuously updated” using digital manufacturing techniques such as 3-D printing.

The benefits could be huge: research would cost less, the equipment would improve each year, grant competition would be less inflamed and educational tools would provide better inspiration and instruction. Outside the lab, open source tools could help spur innovation and diversity in the science manufacturing market. While these big impacts would take time to grow, Pearce and his Michigan Tech Open Sustainability Technology lab did quantify the impact of open source syringe pumps.

Making an Accessible Syringe Pump

Syringe pumps are ubiquitous and an iconic scientific tool. Their prices range from several hundred bucks to a couple of thousand dollars, and depending on how they’re used, the designs vary.

Pearce and his group created 3-D printable models—completely customizable—for $97 for a single pump and $154 for a double pump, using open source CAD software and off-the-shelf motor parts. They posted the designs and codes on Youmagine and Thingiverse; within ten months, they had 1,035 downloads. And each download counterbalances the cost of purchasing a syringe pump.

“We know at the very least that our design is more cost-effective than low end syringe pumps,” Pearce says. “You look at our syringe pump, and it’s way better than the low end ones—it matches performance of high end syringe pumps that anyone can build themselves.”

To calculate a return on investment, the team examined the download substitution value. Basically, they took the price of a syringe pump and the cost of manufacturing their own tool design—the difference between them represents a savings. Then they multiplied that savings by the number of people who downloaded the design and made the tool. Pearce and his team estimate the return on investment for this case study is between 460 percent and 12,000 percent.

Read more: Making a Difference with Open Source Science Equipment

The Latest on: Open Source Science Equipment

[google_news title=”” keyword=”Open Source Science Equipment” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Open Source Science Equipment

- Russian Gains, U.S. Aid, Kremlin Shakeup: State of the Ukraine Waron May 19, 2024 at 3:00 am

The Cipher Brief spoke with three former Senior CIA Officers to discuss the state of the Ukraine war as Russia gains momentum.

- Nation’s First Commercial Hydrogen Fueling Station to Openon May 17, 2024 at 9:36 am

The truck fueling station, set to open this summer in West Oakland, has the potential over six years to stop nearly 25,000 metric tons of carbon dioxide from fouling the air and harming nearby ...

- How AI Could Shake Up Your Future Fitness Routineon May 16, 2024 at 6:00 am

AI is making waves in just about every industry you could name.AI technology isn't particularly new in the fitness world. It's used in smartwatches, smart mirrors, smart home gyms (like Tonal and ...

- Scientific & Medical Equipment Houseon May 14, 2024 at 5:00 pm

Source: FactSet Indexes ... Change value during the period between open outcry settle and the commencement of the next day's trading is calculated as the difference between the last trade and ...

- Superheavy Elements Are Breaking the Periodic Tableon May 14, 2024 at 6:00 am

A t the far end of the periodic table is a realm where nothing is quite as it should be. The elements here, starting at atomic number 104 (rutherfordium), have never been found in nature. In fact, ...

- Is private 5G too technologically advanced?on May 14, 2024 at 1:40 am

webinar, noting that his company had around $40 million in “open pipeline” a year ago ... better served with a more simplified technology package using a single-source of equipment or relying on an ...

- Experience the Wonders of Marine Science Up-Close at a Free Coral Lab Open Houseon May 10, 2024 at 4:44 pm

The marine science team for the Butler Bay Coral Restoration Project will host an up-close marine science experience at a free open house event at the project’s pop-up coral laboratory at the Feather ...

- Analysis: will US export curbs on proprietary AI models be effective?on May 10, 2024 at 5:14 am

Experts are questioning how effective curbs on proprietary AI software will be as the industry increasingly veers towards open source.

- Special Issue on Open Science Policies as an Accelerator for Achieving the Sustainable Development Goalson December 21, 2022 at 11:20 am

including access to open source scientific equipment. This article discusses how conventional, black box, proprietary approaches to science hardware reinforce inequalities in science and slow down ...

- scientific equipmenton February 5, 2022 at 3:59 pm

The principles of open-source hardware are starting to make great strides in scientific research fields. [Walker Arce] tells us about his paper co-authored with [Jeffrey R. Stevens], about a dog ...

via Bing News