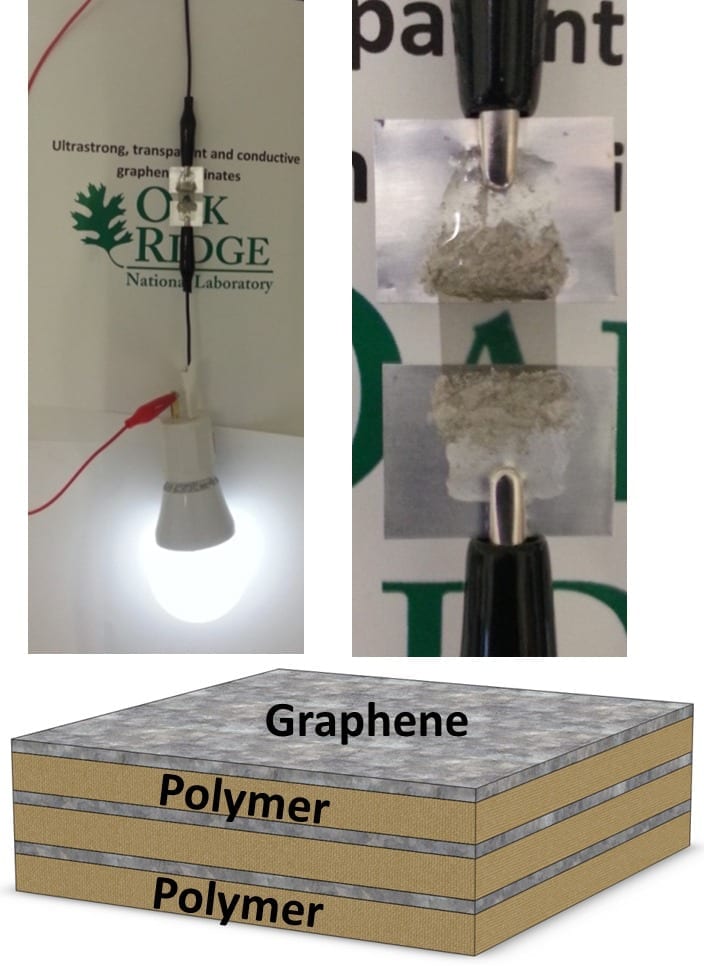

One of the barriers to using graphene at a commercial scale could be overcome using a method demonstrated by researchers at the Department of Energy’s Oak Ridge National Laboratory.

Graphene, a material stronger and stiffer than carbon fiber, has enormous commercial potential but has been impractical to employ on a large scale, with researchers limited to using small flakes of the material.

Now, using chemical vapor deposition, a team led by ORNL’s Ivan Vlassiouk has fabricated polymer composites containing 2-inch-by-2-inch sheets of the one-atom thick hexagonally arranged carbon atoms.

The findings, reported in the journal Applied Materials & Interfaces, could help usher in a new era in flexible electronics and change the way this reinforcing material is viewed and ultimately used.

“Before our work, superb mechanical properties of graphene were shown at a micro scale,” said Vlassiouk, a member of ORNL’s Energy and Transportation Science Division. “We have extended this to a larger scale, which considerably extends the potential applications and market for graphene.”

While most approaches for polymer nanocomposition construction employ tiny flakes of graphene or other carbon nanomaterials that are difficult to disperse in the polymer, Vlassiouk’s team used larger sheets of graphene. This eliminates the flake dispersion and agglomeration problems and allows the material to better conduct electricity with less actual graphene in the polymer.

“In our case, we were able to use chemical vapor deposition to make a nanocomposite laminate that is electrically conductive with graphene loading that is 50 times less compared to current state-of-the-art samples,” Vlassiouk said. This is a key to making the material competitive on the market.

If Vlassiouk and his team can reduce the cost and demonstrate scalability, researchers envision graphene being used in aerospace (structural monitoring, flame-retardants, anti-icing, conductive), the automotive sector (catalysts, wear-resistant coatings), structural applications (self-cleaning coatings, temperature control materials), electronics (displays, printed electronics, thermal management), energy (photovoltaics, filtration, energy storage) and manufacturing (catalysts, barrier coatings, filtration).

Read more: ORNL demonstrates first large-scale graphene composite fabrication

The Latest on: Large-scale graphene composite fabrication

[google_news title=”” keyword=”Large-scale graphene composite fabrication” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Large-scale graphene composite fabrication

- Enhancing Electronics with Advanced Composite Phase Change Materialson May 7, 2024 at 5:42 am

Composite PCMs enhance thermal management in electronics, offering improved heat dissipation and device longevity.

- Graphene Manufacturing Group Announces Pricing of Marketed Unit Offeringon April 26, 2024 at 3:29 am

Graphene Manufacturing Group Ltd. (TSX-V: GMG) (“GMG” or the “Company”) is pleased to announce pricing of its previously announced marketed offering (the “Offering”) of units (the ...

- Alfa Chemistry Intensifies Efforts on Transfer, Manufacturing and Modification of Graphene-Based Silicon-Carbon Compositeson April 24, 2024 at 5:00 pm

Manufacturing of Graphene-Based Silicon-Carbon Composites Graphene-based silicon-carbon composites can be used in new energy vehicles, smartphones, wearable smart devices, large-scale energy storage, ...

- Graphene Manufacturing Group Ltd (GMGMF)on April 21, 2024 at 9:30 am

As of 12:24 PM EDT. Market Open. NOT FOR DISTRIBUTION TO UNITED STATES NEWSWIRE SERVICES OR FOR DISSEMINATION IN THE UNITED STATES BRISBANE, Australia, May 07, 2024 (GLOBE NEWSWIRE) -- Graphene ...

- Composites end markets: Batteries and fuel cells (2024)on April 17, 2024 at 5:00 pm

Firepel R003 resins are designed for use in liquid molding processes such as vacuum infusion, resin transfer molding (RTM) and wet molding for the manufacture of high-performance composite ... process ...

- Can Graphene Be Mass Produced?on April 7, 2024 at 5:00 pm

10 Another study proposes combining ball milling with shear-mixing in supercritical CO 2 for large-scale graphene production ... by up to 20 % through reduced cement content. 16 Graphene manufacturing ...

- Large-scale additive system prints industrial molds for compositeson July 26, 2023 at 5:00 pm

After having established a strong foundation in kinetic models in a previous webinar, part two delves into the exciting realm of machine learning and its transformative potential for composite ...

- Research Areason July 23, 2022 at 4:56 am

The setup in the MDLab’s testbed offers a unique space to study the scaling from more fundamental principles to large-scale functional composites manufacturing. Industry 4.0 represents the fusion of ...

- About the Composites Manufacturing Simulation Centeron October 13, 2021 at 10:53 am

The second accomplishment is the establishment of the Thermwood Large Scale Additive Manufacturing Laboratory in 2021. Thermwood Corporation is the developer of composites additive manufacturing ...

- Global Graphene Companies – Manufacturers and Supplierson August 14, 2020 at 11:38 pm

One of the greatest challenges being faced today in commercializing graphene is how to produce high quality material, on a large scale at ... by reducing the manufacturing costs effectively. The ...

via Bing News