“We think it’s going to change materials research in the future.”

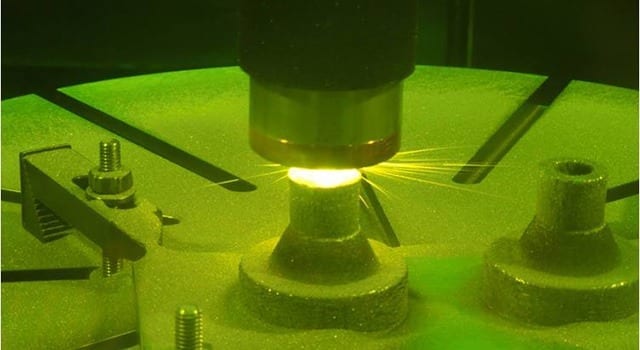

3-D printers can create all kinds of things, from eyeglasses to implantable medical devices, straight from a computer model and without the need for molds. But for making spacecraft, engineers sometimes need custom parts that traditional manufacturing techniques and standard 3-D printers can’t create, because they need to have the properties of multiple metals. Now, researchers at NASA’s Jet Propulsion Laboratory in Pasadena, California, are implementing a printing process that transitions from one metal or alloy to another in a single object.

“You can have a continuous transition from alloy to alloy to alloy, and you can study a wide range of potential alloys,” said R. Peter Dillon, a technologist at JPL. “We think it’s going to change materials research in the future.”

Although gradient alloys have been created in the past in research and development settings, this is the first time these composite materials have been used in making objects, such as a mount for a mirror, said John Paul Borgonia, a JPL mechanical engineer.

Why would you need to make a machine part like this? Say you want a metal object where you would like the ends to have different properties. One side could have a high melting temperature and the other a low density, or one side could be magnetic and the other not. Of course, you could separately make both halves of the object from their respective metals and then weld them together. But the weld itself may be brittle, so that your new object might fall apart under stress. That’s not a good idea if you are constructing an interplanetary spacecraft, for example, which cannot be fixed once it is deployed.

JPL scientists have been developing a technique to address this problem since 2010. An effort to improve the methods of combining parts made of different materials in NASA’s Mars Science Laboratory mission, which safely landed the Curiosity rover on the Red Planet in 2012, inspired a project to 3-D print components with multiple alloy compositions.

Researchers from JPL, the California Institute of Technology, Pasadena, and Pennsylvania State University, University Park, joined forces to tackle the issue. The result has implications for space travel and machinery on our own planet.

Read more . . .

The Latest on: 3D printing metals

[google_news title=”” keyword=”3D printing metals” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: 3D printing metals

- Desktop Metal's Reactive Safety Kit enables binder jet 3D printing of titanium & aluminium materialson May 8, 2024 at 8:01 am

Users of Desktop Metal’s Production System P-1 will now be able to process reactive metals like titanium and aluminium after the company launched the Reactive Safety Kit.

- MIT spin-off Rapid Liquid Print raises $7M for 3D printingon May 7, 2024 at 1:30 pm

MIT spin-off Rapid Liquid Print has raised $7 million in funding for its novel liquid-based 3D printing technology.

- Farsoon introduces large-format 12-laser metal 3D printer at TCT Asiaon May 7, 2024 at 9:46 am

The developer of polymer laser sintering and metal laser melting systems says the FS811M features one of the biggest build volumes on the metal laser powder bed fusion market at 840 × 840 x 960mm.

- This gigantic 3D printer could reinvent manufacturingon May 7, 2024 at 2:00 am

A massive additive manufacturing device that can build houses, and a whole lot more has just been unveiled at the University of Maine.

- Marriage of synthetic biology and 3D printing produces programmable living materialson May 4, 2024 at 10:24 am

Scientists are harnessing cells to make new types of materials that can grow, repair themselves and even respond to their environment. These solid 'engineered living materials' are made by embedding ...

- 3D Printing Finds a Homeon May 2, 2024 at 8:49 am

“Prefabricated 3D printed homes reduce the amount of labor required to build a home, thereby making homes safer, potentially cheaper, and much faster from design to completion,” says Buff López, an ...

- Study unveils 3D printing PQD-polymer architectures at room temperatureon May 2, 2024 at 7:52 am

A technology enabling the fabrication of intricate three-dimensional (3D) quantum dot (QD)-based structures at room temperature has been developed.

- Engineered living materials: Scientists 3D print with bio-ink made from tobacco cellson May 1, 2024 at 5:03 am

Also known as EPLMs, “engineered plant living materials” are a new frontier that marries synthetic biology and 3D printing, an invention that’s inspired many improvements to the mechanism itself as ...

- Crafting Programmable Living Materials With Synthetic Biology & 3D Printingon May 1, 2024 at 4:59 am

New study uses 3D printing and genetically modified plant cells to create complex, self-repairing materials that could revolutionize biomanufacturing and construction. Scientists are harnessing cells ...

- Shhh! 3 Secret 3D Printing Stocks Flying Below Wall Street’s Radaron May 1, 2024 at 3:30 am

InvestorPlace - Stock Market News, Stock Advice & Trading Tips One of the best investment strategies for long-term growth is twofold: pick an ...

via Bing News