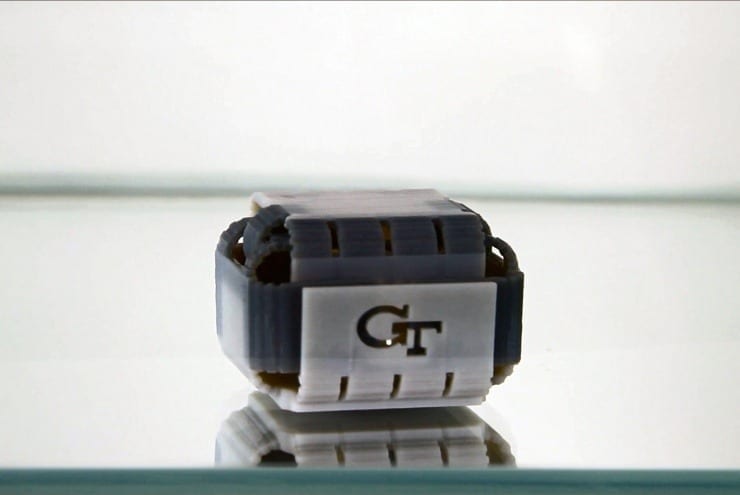

Using components made from smart shape-memory materials with slightly different responses to heat, researchers have demonstrated a four-dimensional printing technology that allowed creation of complex self-folding structures.

The technology, developed by researchers at the Georgia Institute of Technology and the Singapore University of Technology and Design (SUTD), could be used to create 3-D structures that sequentially fold themselves from components that had been flat or rolled into a tube for shipment. The components could respond to stimuli such as temperature, moisture or light in a way that is precisely timed to create space structures, deployable medical devices, robots, toys and range of other structures.

The researchers used smart shape memory polymers (SMPs) with the ability to remember one shape and change to another programmed shape when uniform heat is applied. The ability to create objects that change shape in a controlled sequence over time is enabled by printing multiple materials with different dynamic mechanical properties in prescribed patterns throughout the 3-D object. When these components are then heated, each SMP responds at a different rate to change its shape, depending on its own internal clock. By carefully timing these changes, 3-D objects can be programmed to self-assemble.

The research was reported September 8 in the journal Scientific Reports, which is published by Nature Publishing. The work is funded by the U.S. Air Force Office of Scientific Research, the U.S. National Science Foundation and the Singapore National Research Foundation through the SUTD DManD Centre.

The research creates self-folding structures from 3-D printed patterns containing varying amounts of different smart shape-memory polymers. The patterning, done with a 3-D printer, allows the resulting flat components to have varying temporal response to the same stimuli. Earlier methods required application of differential heating at specific locations in the flat structure to stimulate the shape changes.

“Previous efforts to create sequential shape changing components involved placing multiple heaters at specific regions in a component and then controlling the on-and-off time of individual heaters,” explained Jerry Qi, a professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech. “This earlier approach essentially requires controlling the heat applied throughout the component in both space and time and is complicated. We turned this approach around and used a spatially uniform temperature which is easier to apply and then exploited the ability of different materials to internally control their rate of shape change through their molecular design.”

The team demonstrated the approach with a series of examples including a mechanism that can be switched from a flat strip into a locked configuration as one end controllably bends and threads itself through a keyhole. They also demonstrated a flat sheet that can fold itself into a 3-D box with interlocking flaps. These examples all require the precise control of the folding sequence of different parts of the structure to avoid collisions of the components during folding.

“We have exploited the ability to 3-D print smart polymers and integrate as many as ten different materials precisely into a 3-D structure,” said Martin L. Dunn, a professor at Singapore University of Technology and Design who is also the director of the SUTD Digital Manufacturing and Design Centre. “We are now extending this concept of digital SMPs to enable printing of SMPs with dynamic mechanical properties that vary continuously in 3-D space.”

The team used companion finite element simulations to predict the responses of the 3-D printed components, which were made from varying ratios of two different commercially-available shape-memory polymers. A simplified reduced-order model was also developed to rapidly and accurately describe the physics of the self-folding process.

“An important aspect of self-folding is the management of self-collisions, where different portions of the folding structure contact and then block further folding,” the researchers said in their paper. “A metric is developed to predict collisions and is used together with the reduced-order model to design self-folding structures that lock themselves into stable desired configurations.”

The research team envisions a broad range of applications for their technology. For example, an unmanned air vehicle might change shape from one designed for a cruise mission to one designed for a dive. Also possible would be 3-D components designed to fold flat or be rolled up into tubes so they could be easily transported, and then later deformed into their intended 3D configuration for use.

Read more: 4-D Technology Allows Self-folding of Complex Objects

The Latest on: 4D printing

[google_news title=”” keyword=”4D printing” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: 4D printing

- Ole Miss professor receives NSF grant for work on 4D printingon April 23, 2024 at 3:52 pm

A University of Mississippi engineering professor has won the National Science Foundation's most prestigious award for early career researchers for his upcoming work in 4D printing.

- UM mechanical engineering professor earns NSF CAREER Awardon April 21, 2024 at 5:00 pm

A University of Mississippi engineering professor has won the National Science Foundation's most prestigious award for early career researchers for his upcoming work in 4D printing. The National ...

- Mechanical Engineering Professor Receives NSF CAREER Awardon April 19, 2024 at 6:58 am

The National Science Foundation awarded Yiwei Han, assistant professor of mechanical engineering, with an NSF Faculty Early Career Development Program grant. The award allots more than $576,000 toward ...

- 4D Printed robot dances and crawls via temperature shiftson April 14, 2024 at 5:00 pm

4D printing of the liquid crystal elastomer (LCE) soft crawling robot. a) Schematic diagram of Hot-DIW 4D printing of LCEs. b) Effect of print speed and air pressure on the actuation strains. c) ...

- How 4D printing brings a temporal dimension to additive manufacturingon March 28, 2024 at 5:00 pm

In a world where flexibility and adaptability are the watchwords of transformation, 4D printing is the kind of technology that could offer new solutions. This additive manufacturing technique prod ...

- Harvard Scientists Develop Faster 3D-Printing Method Inspired By Jackson Pollockon November 3, 2023 at 10:30 am

Opinions expressed by Forbes Contributors are their own. I write about the intersection of art, science and technology. A staff member at London's Royal Academy studies the Jackson Pollock ...

- 4D printing process (IMAGE)on July 23, 2023 at 3:01 pm

Specially created software turns an input 3D model, which can be a scan of an existing object, into a 2D pattern that can then be printed. The prints can then be submersed in hot water to self ...

- DIY Self-Assembling 4D Printingon November 28, 2022 at 8:45 pm

The last time we saw 4D printing, there were magnets involved. We think this is an exciting time where people aren’t just trying to get conventional printing to work well, but are pushing the ...

- 4D printingon November 28, 2022 at 4:00 pm

The last time we saw 4D printing, there were magnets involved. We think this is an exciting time where people aren’t just trying to get conventional printing to work well, but are pushing the ...

- Stay smart: it’s all about the materials for 4D printing in biomedicineon April 28, 2021 at 5:00 pm

Where 3D printing was characterized by the new technologies and machinery, 4D printing is defined by the smart materials making waves in drug development and regenerative medicine. The development of ...

via Bing News